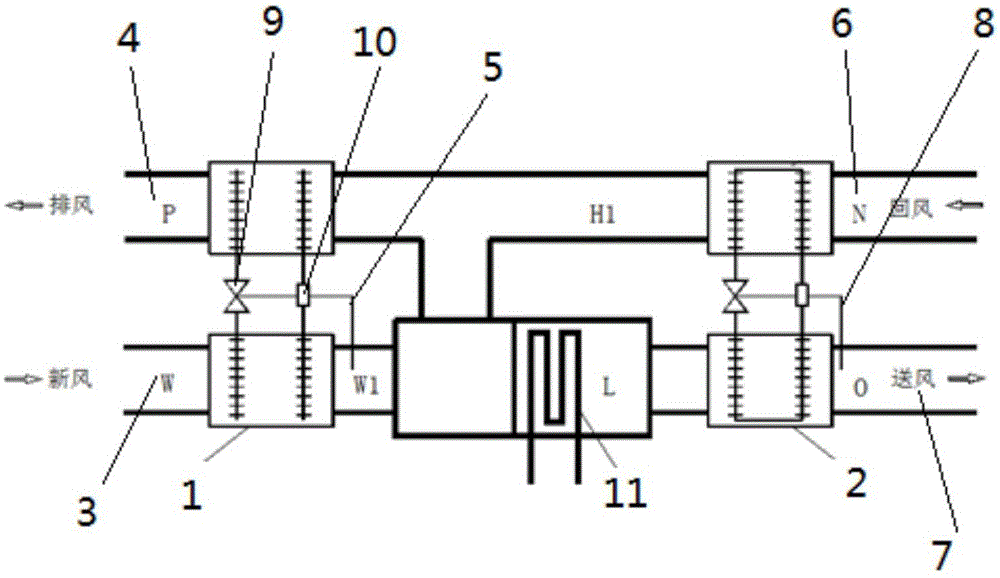

Secondary heat recovery heat-tube type air conditioning system

An air-conditioning system, heat pipe type technology, applied in the field of secondary heat recovery heat pipe type air-conditioning system, can solve the problems of high energy consumption and non-environmental protection of air-conditioning, and achieve the effects of protecting the environment, saving energy, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0014] Taking Hefei as an example, the outdoor design temperature in winter is -7°C, the relative humidity is 75%, the indoor design temperature is 18°C, and the relative humidity is 50%; the outdoor design temperature in summer is 35°C, the relative humidity is 81%, and the indoor design temperature The temperature is 26°C and the relative humidity is 60%. The air supply volume in winter and summer is 5000m 3 / h, of which the fresh air volume accounts for 30% of the total air supply volume. Under the same outdoor air conditions, interior design requirements and air supply conditions, the energy consumption of air conditioners without heat pipe heat recovery systems in winter and summer is 27.17KW and 86.33KW respectively; The heat pipe heat recovery system is 21.17KW and 64.17KW, which can save energy in both winter and summer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com