Multifunctional leaf collecting vehicle

A collection vehicle and multi-functional technology, which is applied in solid separation, construction, and separation of solids from solids with airflow, can solve the problems that leaves cannot be used in time, the efficiency of leaves is not obvious, and the suction cup area is not large, etc., to achieve The effect of high degree of automation, beautification of city appearance and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Working process of the present invention is:

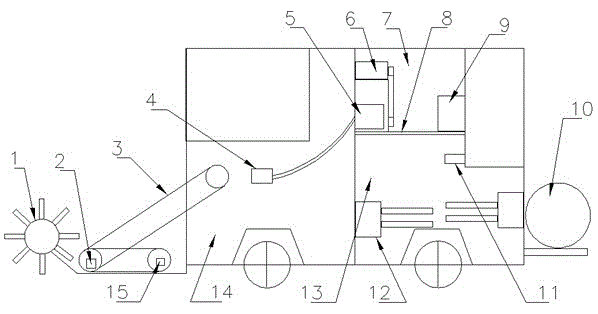

[0015] A kind of multifunctional leaf collection vehicle, comprising a car body, a rolling brush 1 is arranged at the lower part of the front end of the car body, and the rolling brush 1 is connected with a brush motor 2; Slope-type conveyor belt 3, the conveyor belt 3 is driven by the conveyor belt motor 15, the front end of the conveyor belt 3 is adapted to the rolling brush 1, including the adaptation of each movement and width during work, and the rear end of the conveyor belt 3 extends into the garbage bin 14 ; At the rear end exit of the conveyor belt 3, a suction nozzle 4 is arranged, and its structure is a bell mouth, and the suction nozzle 4 is connected with the spiral cutter 5 arranged in the collection bin 7 through a conduit; a blower 9 is provided in the collection bin 7; Both the cutter 5 and the blower 9 are connected with the drive motor 6; two side-by-side baffles 8 are arranged below the helical cutter 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com