Spray non-woven spinning device and spray non-woven spinning method for producing micro-nanofibers

A micro-nano fiber, non-woven technology, used in fiber processing, textile and papermaking, filament/thread forming, etc., to achieve the effects of easy operation, fine fiber diameter, and good fiber web uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

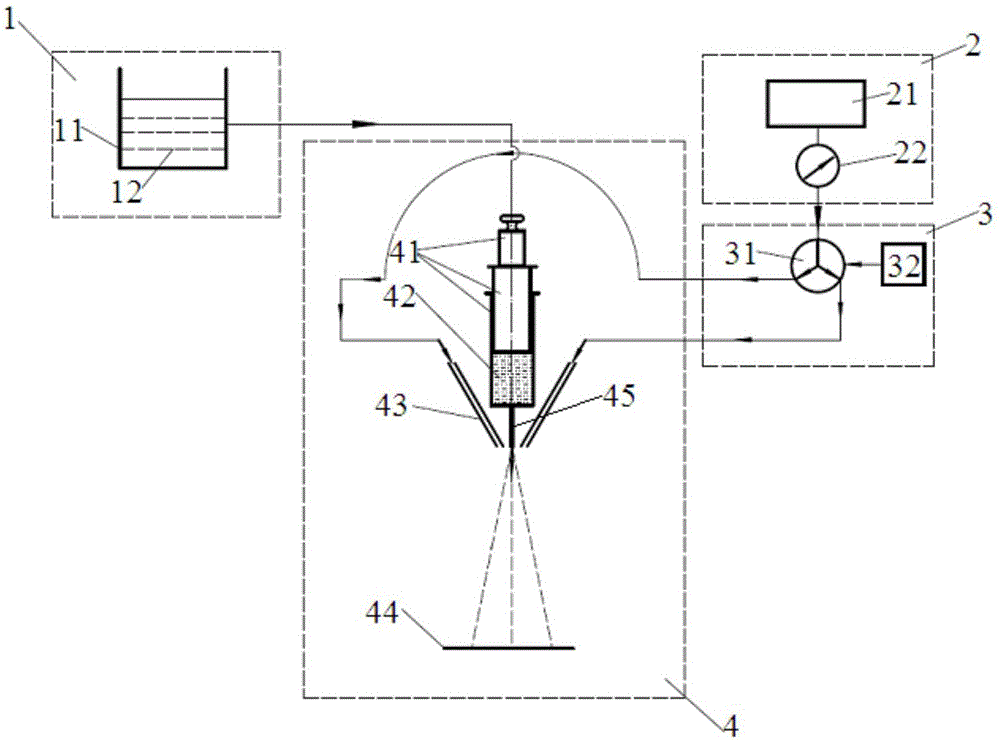

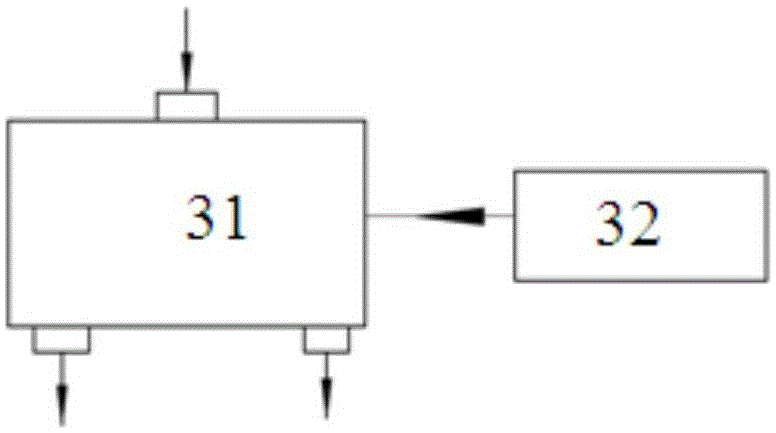

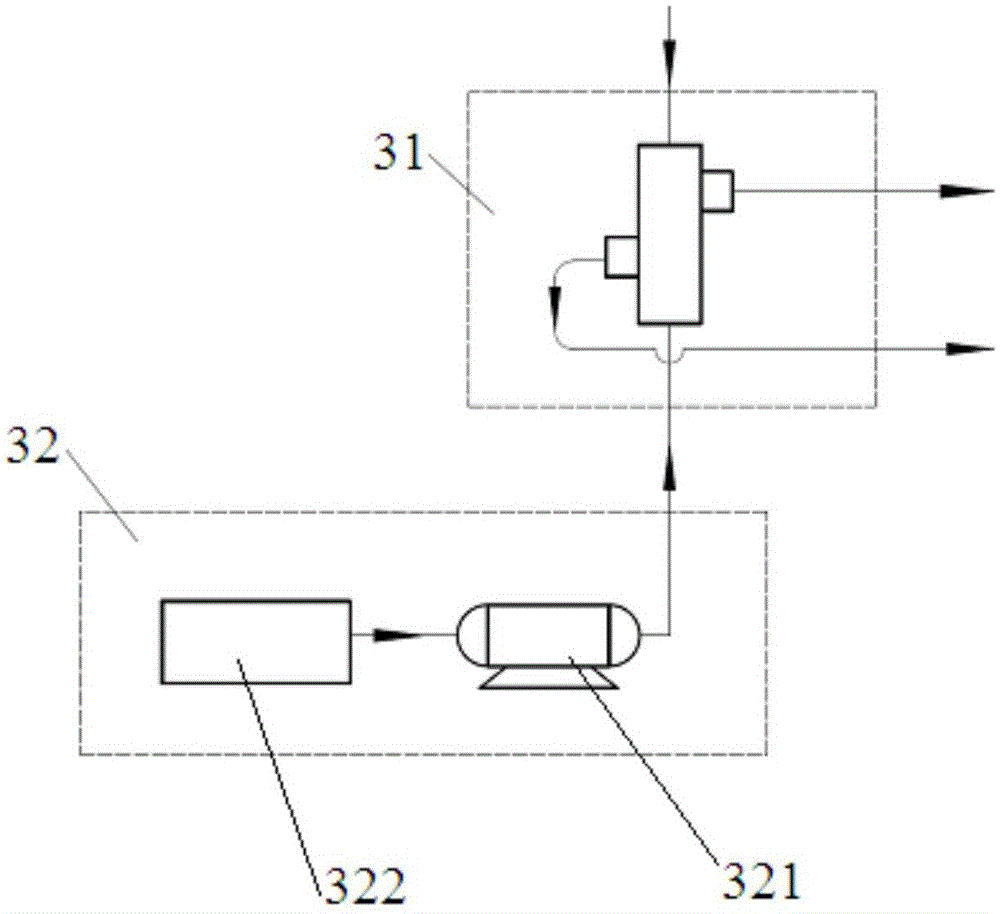

[0040] A device for producing liquid jet nonwoven spinning of micro-nano fibers, such as figure 1As shown, it includes a polymer solution input unit 1 , an air flow input unit 2 , an alternating jet flow generating unit 3 and a liquid jet nonwoven spinning unit 4 . The polymer solution input unit 1 is a solution container 11 for containing the polymer solution 12, and its function is to provide the solution raw material for liquid jet spinning. The air flow input unit 2 includes an air source 21 and a pressure gauge 22, and its function is to provide air with a constant pressure jet source. The liquid jet nonwoven spinning unit 4 is respectively connected with the polymer solution input unit 1 and the alternating jet flow generating unit 3, and the alternating jet flow generating unit 3 is also connected with the airflow input unit 2, and the liquid jet nonwoven spinning unit 4 includes a solution pressure pushing device 41, a solution storage chamber 42, an air jet tank 43, ...

Embodiment 2

[0052] Polyethylene oxide (PEO) was dissolved in distilled water, and a solution with a concentration of 7% was prepared by stirring and heating. Regulate air pressure valve, allow pressure value 0.26Mpa, the internal diameter of spinneret hole is 0.4 millimeter, start spinning, the final fiber diameter that the spinning of ejection forms under the situation that does not use device of the present invention (continuous air flow) is 0.5 Micron.

Embodiment 3

[0054] Liquid jet nonwoven spinning with alternating jet frequency of 1 Hz (using such as Figure 4 Alternating jet generator shown).

[0055] According to the concentration of the solution in Example 2, the pressure and the diameter of the spinneret hole are set, and the speed value of 60 revolutions per minute is input into the PC controller, then an alternating jet with a frequency of 1 Hz can be obtained from the air flow output part, and then the pipes are respectively opened for air flow input The part, the alternating jet flow generating part and the variable frequency motor, start spinning, receive the fiber, and measure the fiber diameter to obtain a final fiber diameter of 0.46 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com