Device and method for recovering disulfide from condensate oil desulfurized alcohol and alkali liquor

A technology for disulfide and desulfurization, which is applied in the field of devices for desulfurization of condensate and regeneration of lye to recover disulfides, can solve the problem of large consumption of alkali residues and discharge of alkali residues, corrosion of condensate oil fractionation devices, Problems such as corrosion of downstream condensate processing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

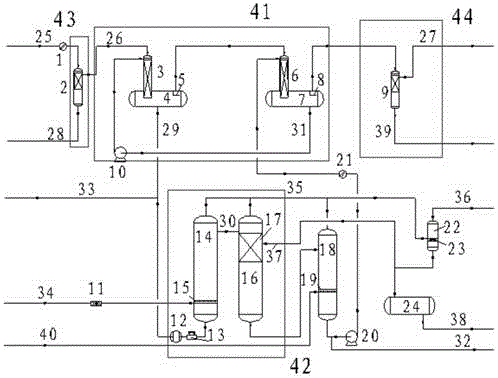

[0085] Such as figure 1 As shown, the condensate oil enters the device through the feed pipe 25, and the condensate oil feed pipe 25 is connected to the condensate oil filter 1 and the coalescence dehydrator 2, and the condensate oil is filtered through the condensate oil filter 1 to remove mechanical impurities, The entrained water is removed through the coalescing dehydrator 2, the oily sewage pipe 28 is connected to the bottom of the coalescing dehydrator 2, and the coalescing dehydrator 2 is connected to the first-stage liquid film contactor 3 through the condensate oil connecting pipe 26, and the first-stage liquid film contactor 3 The contactor 3 is installed on the primary sweetening separation tank 4 through a flange, and the top of the primary sweetening separation tank 4 has a condensate oil outlet, and the condensate oil outlet is provided with a first-stage sweetening separation tank condensate oil outlet stop in the tank Plate 5, the condensate oil outlet is conne...

Embodiment 2

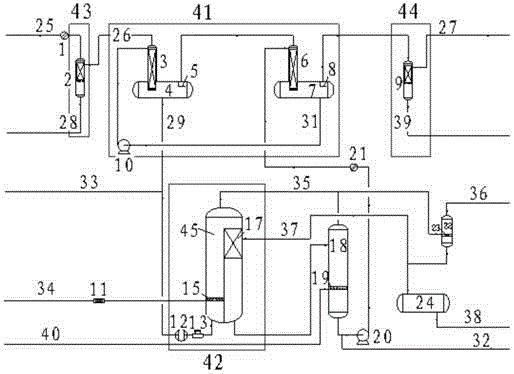

[0087] Such as figure 2 As shown, the condensate oil enters the device through the condensate oil feed pipe 25, and the condensate oil feed pipe 25 is connected to the condensate oil filter 1 and the coalescence dehydrator 2, and the condensate oil is filtered and removed by the condensate oil filter 1 Mechanical impurities are removed from the entrained water through the coalescing dehydrator 2. The oily sewage pipe 28 is connected to the bottom of the coalescing dehydrator 2. The coalescing dehydrator 2 is connected to the first-stage liquid film contactor 3 through the condensate oil connecting pipe 26. The first-stage liquid film contactor 3 is installed on the first-stage sweetening separation tank 4 through a flange, and the top of the first-stage sweetening separation tank 4 has a condensate oil outlet, and the condensate oil outlet is provided with a baffle 5 in the tank, and the condensate oil The outlet is connected to the secondary liquid film contactor 6 through t...

Embodiment 3

[0089] Such as Figure 9As shown, the condensate oil enters the device through the feed pipe 25, and the condensate oil feed pipe 25 is connected to the condensate oil filter 1 and the coalescence dehydrator 2, and the condensate oil is filtered through the condensate oil filter 1 to remove mechanical impurities, The entrained water is removed through the coalescing dehydrator 2, the oily sewage pipe 28 is connected to the bottom of the coalescing dehydrator 2, and the coalescing dehydrator 2 is connected to the first-stage liquid film contactor 3 through the condensate oil connecting pipe 26, and the first-stage liquid film contactor 3 The contactor 3 is installed on the primary sweetening separation tank 4 through a flange. There is a condensate oil outlet on the top of the primary sweetening separation tank 4. The condensate oil outlet is provided with a baffle 5 in the tank. The condensate oil outlet passes through the condensate The oil analysis connecting pipe 26 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com