Water-based anti-dazzle UV coating, hard coated film and preparation method of hard coated film

A hardened film, water-based technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problem that the hardness and wear resistance of the coating film are not as good as those of solvent-based anti-glare UV coatings, and the tightness is not as good as that of solvent-based anti-glare UV coatings. low level problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

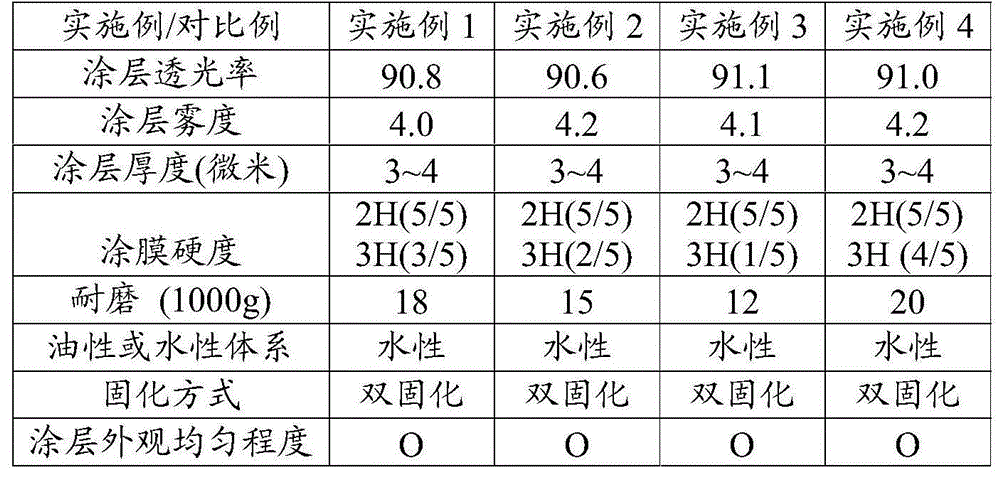

Examples

preparation example Construction

[0058] The present invention also provides a kind of preparation method of cured film, comprises the following steps:

[0059] A) In parts by weight, 30-90 parts of water-based urethane acrylate prepolymer, 10-60 parts of diluted monomer, 5-100 parts of anti-glare particles, 0.05-10 parts of water-based wetting and dispersing agent, 0.05-5 1 part of water-based leveling agent, 1-20 parts of water, 0.5-10 parts of water-based photoinitiator and 1-30 parts of water-based isocyanate curing agent are mixed to obtain a water-based anti-glare UV coating;

[0060] B) coating the water-based anti-glare UV coating obtained in the step A) on the surface of the substrate, and irradiating with ultraviolet light to obtain a semi-finished hardened film;

[0061] C) thermally curing the semi-finished cured film obtained in step B) to obtain a cured film.

[0062] The present invention is preferably prepared according to the dosage of each component in the step A) and according to the prepar...

Embodiment 1

[0073] The raw materials and consumption (parts by weight) used in this embodiment are shown in Table 1.

[0074] Raw material and consumption of table 1 embodiment of the present invention 1

[0075] Waterborne polyurethane acrylate

UCECOAT 7200

40 copies

Aliphatic Polyurethane Dispersions

UCECOAT 7699

20 copies

pentaerythritol triacrylate

EM 235

20 copies

Dipentaerythritol Pentaacrylate

Miramer M500

20 copies

Deionized water

Deionized water

10 copies

2-Hydroxy-4'-(2-hydroxyethoxy)-2-methylpropiophenone

IRGACURE 2959

2 copies

1-Hydroxy-cyclohexyl-phenylmethanone

IRGACURE 184

3 copies

Silica matting powder

HP230 slurry

10 copies

Organically modified 500nm silica

NSI 500P

10 copies

10-15nm silicon dioxide

IPA-ST

20 copies

Alkanolamine with acidic group polymer copolyester

DISPERBYK-180

0.4 parts

Polyether ...

Embodiment 2

[0085] The raw materials and consumption (parts by weight) used in this embodiment are shown in Table 2.

[0086] Raw material and consumption of table 2 embodiment of the present invention 2

[0087] Waterborne Aliphatic Polyurethane Dispersions

UCECOAT 7655

40 copies

Waterborne polyurethane acrylate

UCECOAT 7200

20 copies

dipentaerythritol hexaacrylate

EM 264

15 copies

pentaerythritol triacrylate

EM 235

25 copies

Deionized water

Deionized water

5 copies

2-Hydroxy-2-methyl-1-phenyl-1-propanone

IRGACURE 1173

3 copies

2-Hydroxy-4'-(2-hydroxyethoxy)-2-methylpropiophenone

IRGACURE 2959

2 copies

Silica matting powder

OK 520

10 copies

Organically modified 600nm silica

NSI 650S

8 servings

70~100nm silicon dioxide

IPA-ST-L

15 copies

Pigment affinity group polymer interpolymer

DISPERBYK-184

0.3 parts

Polyether mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com