Metal piece surface imitative copper plating technique

A technology for metal parts and copper plating, applied in the field of green technology, can solve the problems of high energy consumption and great harm to health, and achieve the effects of low energy consumption, pollution avoidance and low raw material prices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with embodiment the present invention is described in further detail.

[0028] Taking the cast steel workpiece as an example to illustrate the imitation copper plating process on the surface of metal parts, it includes the following steps:

[0029] 1) Shot blasting is performed on the surface of the cast steel workpiece to remove burrs and oil stains on the surface. Shot blasting is a conventional method.

[0030] 2) Spray a layer of primer on the treated substrate surface.

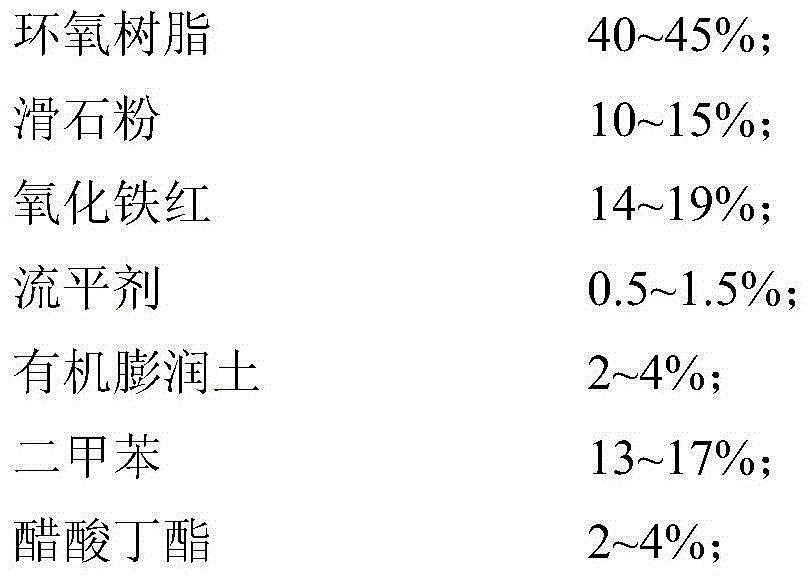

[0031] The primer includes a primer composition and a first diluent. Wherein primer composition comprises following quality composition:

[0032]

[0033] The leveling agent can be selected from conventional leveling agents in the prior art as required.

[0034] The mass composition of the first diluent is:

[0035]

[0036] The mixing ratio of the primer composition and the first thinner is 1:0.5-0.6, and the viscosity of the paint is adjusted to 15S by using a Tu 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com