A preparation method of binary copolymerized fluorescent microsphere emulsion for measuring dissolved oxygen concentration

A binary copolymerization fluorescence, dissolved oxygen concentration technology, applied in the direction of fluorescence/phosphorescence, material excitation analysis, etc., can solve the problems of easy leakage and stability of indicators, low oxygen sensitivity, and non-environmental solvents, etc., to achieve long-term preservation, Excellent monodispersity and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0031] Embodiment 1: A method for preparing a binary copolymerized fluorescent microsphere emulsion for measuring dissolved oxygen concentration in this embodiment is carried out in the following steps:

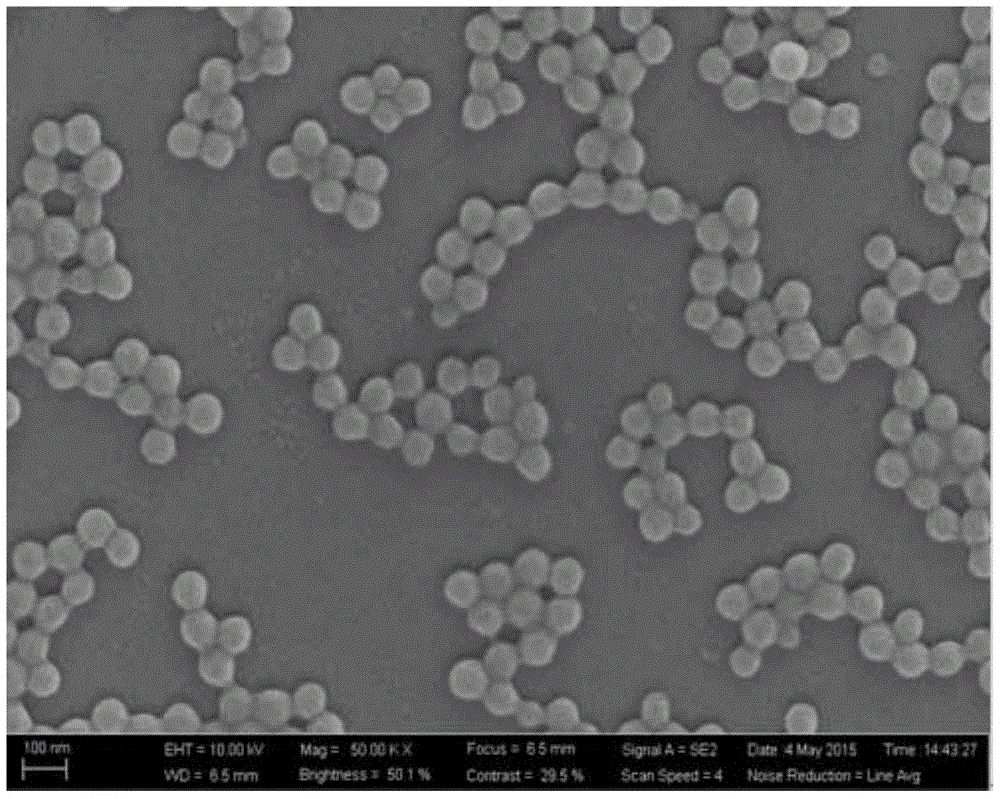

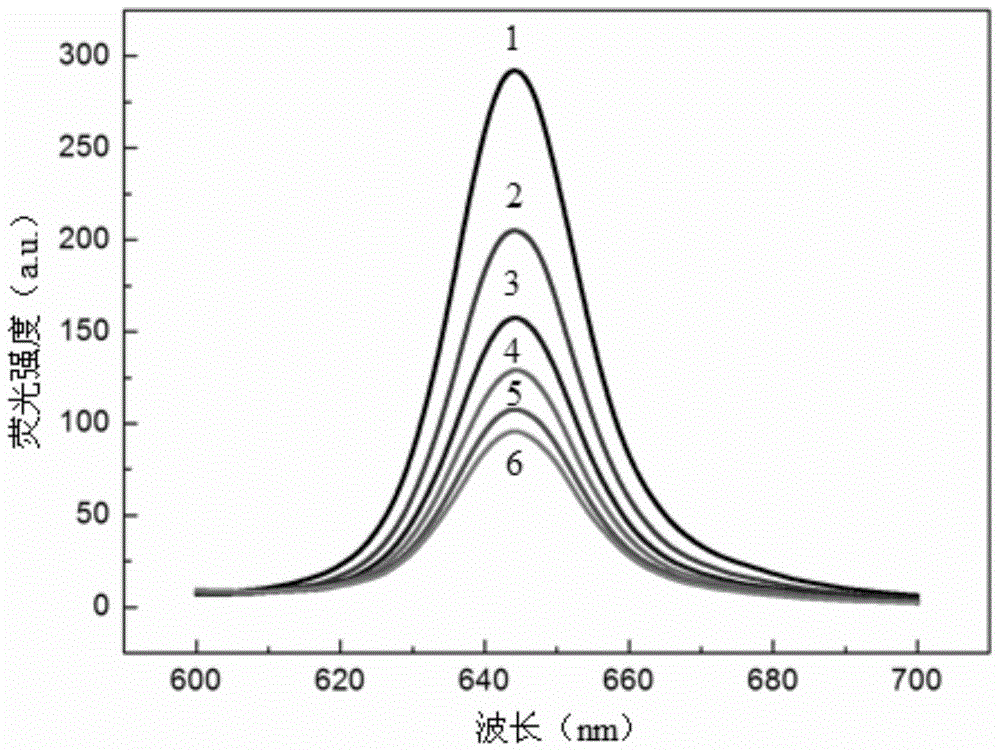

[0032] Mix methyl methacrylate and trifluoroethyl methacrylate to obtain a copolymer emulsion, then add octaethylporphyrin platinum to the copolymer emulsion, mix well and then add azobisisobutyronitrile and dodecane Sodium sulfate, stir for 0.8h to 1.2h at a temperature of 35 to 45°C and a rotational speed of 250r / min to 300r / min, add ultrapure water and ultrasonicate at room temperature and at an ultrasonic frequency of 20kHz to 45kHz 2min to 4min, and then reflux reaction at a temperature of 60-70°C for 4.5h-5.5h to obtain a binary copolymerized fluorescent microsphere emulsion;

[0033] The volume ratio of the methyl methacrylate to trifluoroethyl methacrylate is 1: (1.5-2.5);

[0034] The ratio of the volume sum of the methyl methacrylate and trifluoroethyl methacrylate...

specific Embodiment approach 2

[0038] Embodiment 2: This embodiment is different from Embodiment 1 in that: the volume ratio of methyl methacrylate to trifluoroethyl methacrylate is 1:2. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0039] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the ratio of the volume sum of methyl methacrylate and trifluoroethyl methacrylate to the mass of platinum octaethylporphyrin For 9mL: 8mg. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com