A kind of south red soil dry land nutrient expansion conditioner and preparation method thereof

A conditioner and soil nutrient technology, applied in the field of soil agricultural chemistry, can solve the problem of limited expansion effect of red soil nutrients, and achieve the effects of increasing soil porosity and the proportion of large aggregates, strong water absorption and water retention performance, and reducing soil bulk density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

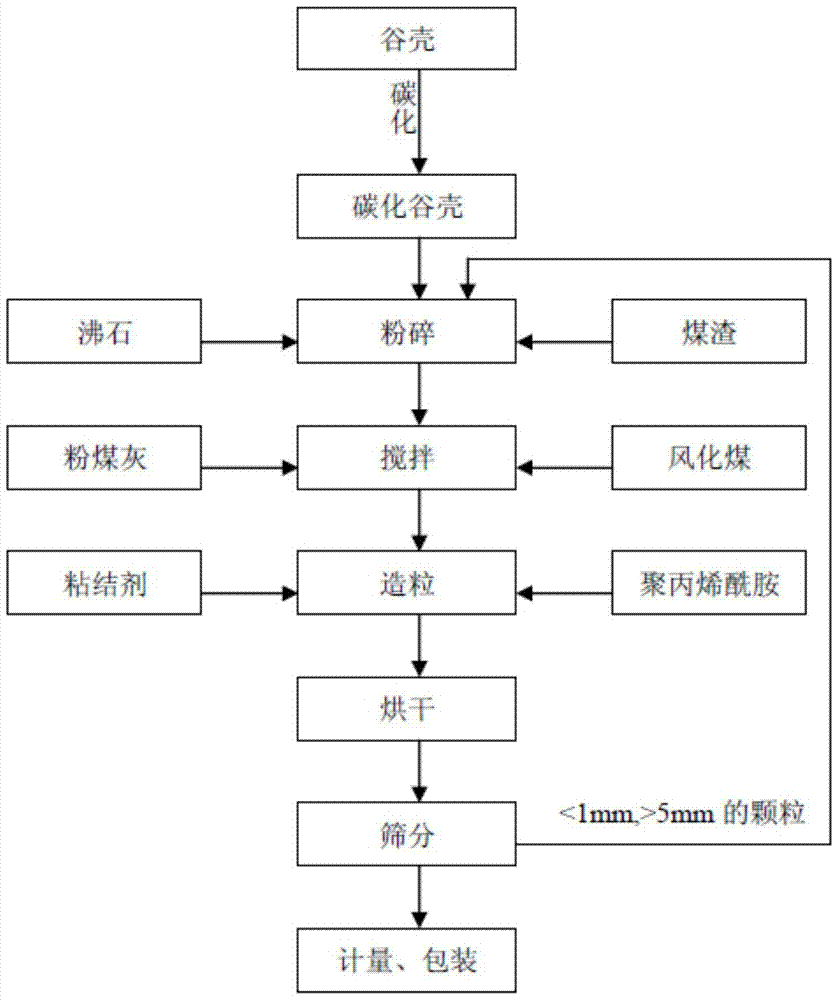

[0031] Step 1: Prepare Carbonized Chaff

[0032] Place the chaff in a carbonization furnace for high-temperature carbonization. The temperature is controlled at 500-600° C., and the carbonization takes about 12 hours. After the carbonization is completed, it is forced to ventilate and cooled to room temperature to obtain carbonized chaff.

[0033] Step 2: Material crushing

[0034] Taking the weight of the soil nutrient expansion conditioning agent as the weight percentage basis, take 30% of zeolite, 10% of coal cinder and 18% of carbonized chaff in the pulverizer to pulverize by weight;

[0035] Step 3: Material Mixing

[0036] Put the above pulverized material in the mixer, and add 12% of fly ash and 20% of weathered coal according to the weight ratio at the same time, and fully mix to obtain the mixed material;

[0037] Step 4: Granulation

[0038] The above-mentioned mixed material is granulated in a disc granulator, and 5% of bentonite is added at the same time, and 5%...

Embodiment 2

[0042] Step 1: Prepare Carbonized Chaff

[0043] Place the chaff in a carbonization furnace for high-temperature carbonization, the temperature is controlled at 500-600°C, and the carbonization takes about 8 hours. After the carbonization is completed, it is cooled to room temperature by forced ventilation to obtain carbonized chaff.

[0044] Step 2: Material crushing

[0045] Taking the weight of the soil nutrient expansion conditioner as the weight percentage basis, take 30% of zeolite, 10% of coal cinder and 27% of carbonized chaff in the pulverizer according to the proportioning by weight;

[0046]Step 3: Material Mixing

[0047] Put the pulverized material in the mixer, add 20% of weathered coal at the same time, and mix well to obtain the mixed material;

[0048] Step 4: Granulation

[0049] The above-mentioned mixed material is granulated in a disc granulator, and 8% of bentonite is added at the same time, and 5% of polyacrylamide is added after the masterbatch is fo...

Embodiment 3

[0053] Step 1: Prepare Carbonized Chaff

[0054] Place the chaff in a carbonization furnace for high-temperature carbonization. The temperature is controlled at 500-600° C., and the carbonization takes about 20 hours. After the carbonization is completed, it is forced to ventilate and cooled to room temperature to obtain carbonized chaff.

[0055] Step 2: Material crushing

[0056] Taking the weight of the soil nutrient expansion conditioner as the weight percentage basis, taking 35% of zeolite and 10% of coal cinder according to the weight ratio and pulverizing in the pulverizer;

[0057] Step 3: Material Mixing

[0058] Put the pulverized material above into a mixer, add 23% of weathered coal and 14% of fly ash at the same time, and fully mix to obtain a mixed material;

[0059] Step 4: Granulation

[0060] The above-mentioned mixed material is granulated in a disc granulator, and 10% of bentonite is added at the same time, and 8% of polyacrylamide is added after the mast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com