Application of Tailings Chips Partially Substituting Natural Sand and Cementitious Materials in Concrete

A technology of cementitious materials and tailings, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve problems such as difficult control of concrete quality, secondary pollution of water environment, fluctuation of concrete slump, etc. Achieve the effect of saving social wealth, promoting development and reducing encroachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The preferred embodiments of the present invention are given below to describe the technical solution of the present invention in detail.

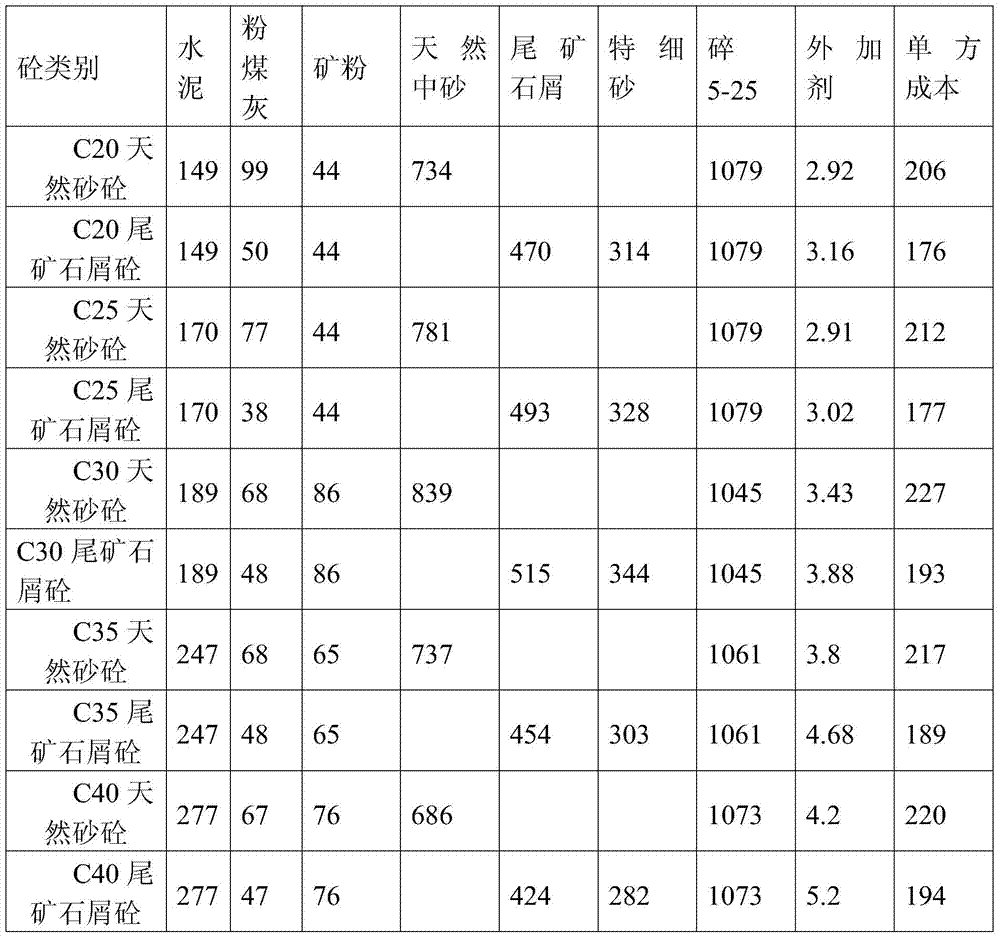

[0010] The present invention adopts tailings chips and ultra-fine sand, and determines that the fineness modulus of tailings chips before mixing is 3.2-3.6, and the fineness modulus of ultra-fine sand is 1.0-1.4. The fineness modulus of the mixed sand after mixing the proportion of %-50% is 2.3-2.6.

[0011] Doped with 1.1%-1.4% polycarboxylate admixture in each square concrete, its concrete water-reducing rate is 25%-30%, and it has good adaptability to tailings debris concrete, and the slump of concrete loses over time in one hour Within 30mm, the shortcomings of poor workability, large water demand, and large loss of slump over time of tailings chip concrete are solved.

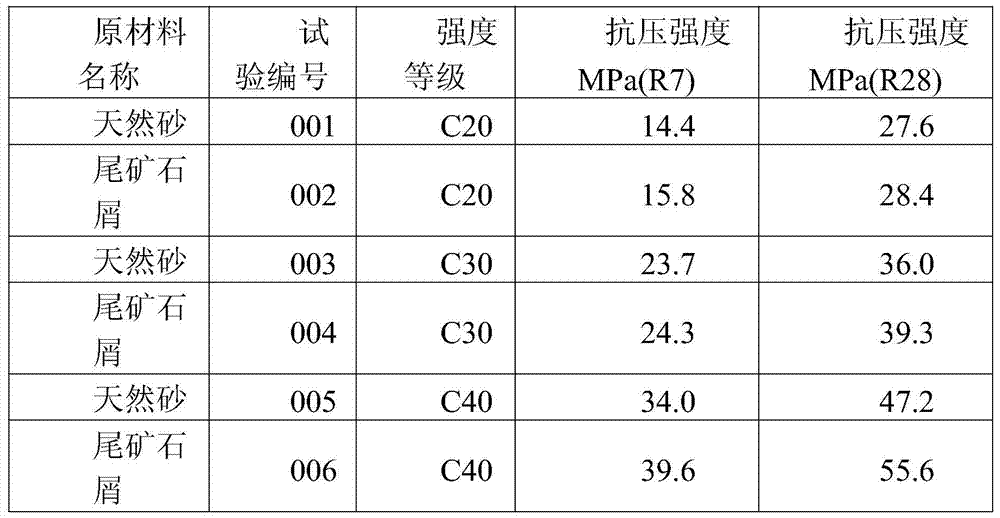

[0012] From the cubic compressive strength test results (Table 1) of tailings chip concrete of various strength grades, it can be seen that commercial concrete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com