Organic wastewater treatment and recycling method

A technology of organic wastewater and pretreatment tank, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Achieve the effect of improving treatment efficiency and slowing down the rate of fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

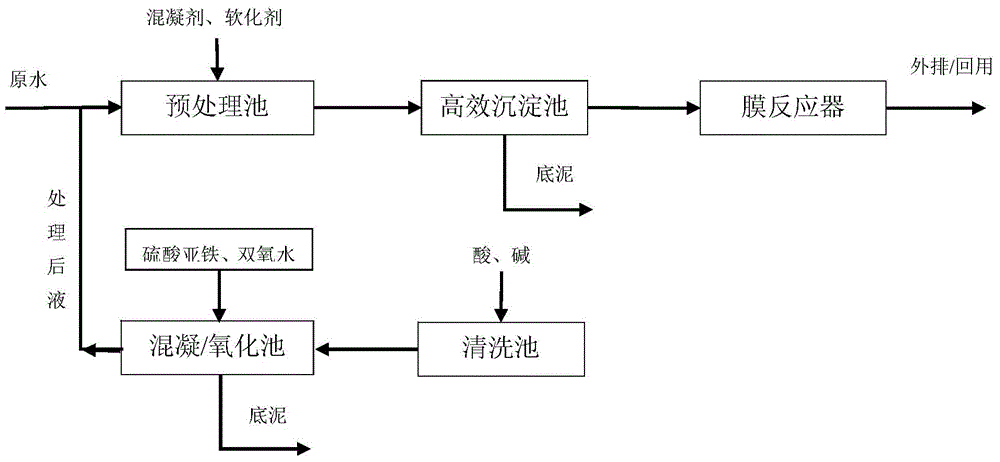

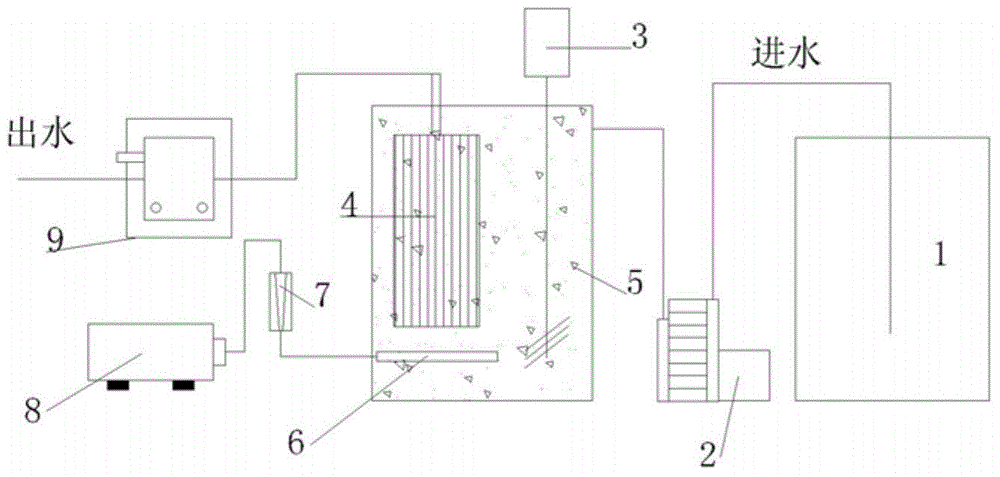

Method used

Image

Examples

Embodiment 1

[0027] A mineral processing wastewater contains toxic and refractory characteristic pollutants such as heavy metals, aniline black, and butyl xanthate. The water quality is as follows: [Pb]=70.35mg L -1 , [Zn 2+ ]=12.26 mg·L -1 , COD cr =400mg·L -1 , BOD 5 =45mg·L -1 ,pH=9.66

[0028] Implementation steps:

[0029] 1) Transport the raw water to the pretreatment tank through the lift pump, and add 40mg L of polyferron to the pretreatment tank -1 , polyacrylamide 5mg·L -1 , and stirred for 30 minutes.

[0030] 2) In step (1), the mixed liquid overflows to the high-efficiency solid-liquid separation tank.

[0031] 3) The effluent from step (2) overflows into the membrane reaction vessel (1 for standby and 1 for use). The average pore size of the PVDF hollow fiber membrane is 0.1 μm, and the membrane module is connected to an external self-priming pump to realize continuous treatment of wastewater. Add 50g L of organically modified bentonite-based adsorbent to the reacto...

Embodiment 2

[0039] A mineral processing wastewater contains characteristic pollutants such as ethyl thiazolin, butyl xanthate, and heavy metals. The water quality is as follows: [Cu]=0.90mg·L -1 , [Zn 2+ ]=0.32 mg L -1 , [Pb 2+ ]=5.59 mg·L -1 , CODcr=350mg·L -1 ,pH=9.25

[0040] Implementation steps:

[0041] 1) Transport the raw water to the pretreatment tank through the lift pump, and add 60mg·L of polyiron to the pretreatment tank -1 , polyacrylamide 5mg·L -1 , and stirred for 20 minutes.

[0042] 2) Step (1) The mixed liquid overflows to the high-efficiency solid-liquid separation tank, and the supernatant is pre-filtered through a security filter with a precision of 50 μm.

[0043] 3) The effluent from step (2) overflows into the membrane reaction vessel (1 for standby and 1 for use). The average pore size of the PVDF hollow fiber membrane is 0.2 μm, and the membrane module is connected to an external self-priming pump to realize continuous treatment of wastewater. Add 100g ...

Embodiment 3

[0052] The characteristic pollutants of a certain printing and dyeing wastewater are high-salt and biorefractory azo dyes. The water quality is as follows: conductivity = 15200μs·cm -1 , COD cr =900mg·L -1 , SS is 180mg·L -1 , chroma=400, pH=7.52.

[0053] Implementation steps:

[0054] 1) Transport the raw water to the pretreatment tank through the lift pump, and add high-efficiency polyaluminum chloride (HPAC) 120mg L to the pretreatment tank -1 , polyacrylamide 2mg·L -1 , and stirred for 20 minutes.

[0055] 2) Step (1) The mixed liquid overflows to the high-efficiency solid-liquid separation tank, and the supernatant is pre-filtered through a security filter with a precision of 30 μm.

[0056] 3) The effluent from step (2) overflows into the membrane reaction vessel (1 for standby and 1 for use). The average pore size of the PVDF hollow fiber membrane is 0.5 μm, and the membrane module is connected to an external self-priming pump to realize continuous treatment of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cod | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com