Method of preparing CdS nano particles through room-temperature solid-phase reaction

A room temperature solid-phase reaction, nanoparticle technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as unsatisfactory results, low degradation efficiency, and achieve high yields , good dispersion, high degree of orientation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation of embodiment 1CdS nanoparticles

[0021] Weigh 3.84g of CdSO 4 ·8H 2 O, 1.2g thiourea, and 2.4g NaOH were ground in an agate mortar for 5 minutes, and 0.5 g of bovine serum albumin was added to continue grinding for 30 minutes to obtain a fine bright light yellow sticky substance. Alternately wash and filter with distilled water and absolute ethanol for 3 times, and dry naturally to obtain light yellow powder, which is stored in N2.

Embodiment 2

[0022] The characterization of embodiment 2 catalyst

[0023] Example 1 The product CdS prepared by solid-state reaction at room temperature is a light yellow powder, which is consistent with the intuitive performance of the quantum size effect of CdS nanoparticles, that is, its color changes from the yellow of the bulk material to the light yellow of the nanoparticles.

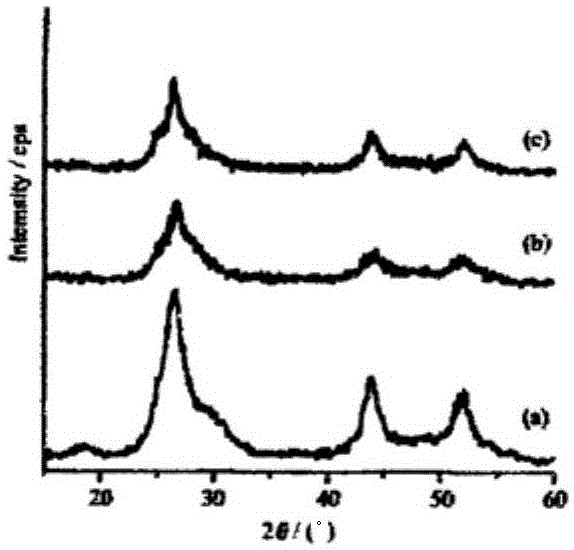

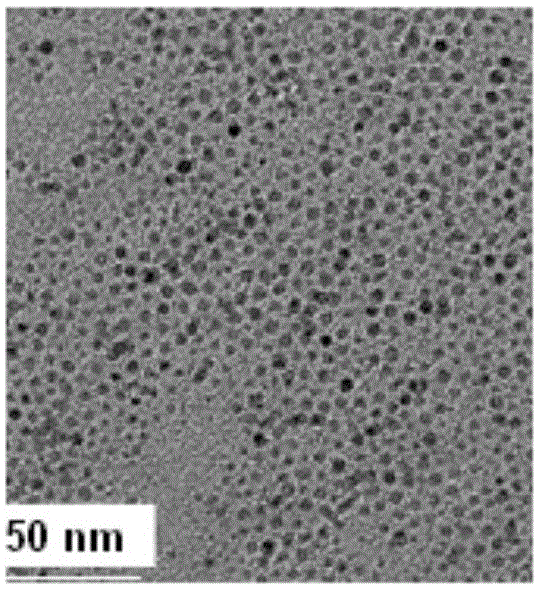

[0024] figure 1 are XRD patterns of products under different conditions. By comparing with the standard PDF card, three strong peaks with 2θ of 26.6°, 44.0°, and 52.2° in (a), (b) and (c) correspond to (111) and (111) of cubic CdS respectively. (220) and (311) crystal planes. It can be known that the CdS particles obtained by solid-phase grinding at room temperature are in the cubic phase crystal form. The XRD pattern also shows that the diffraction peak of the reactant disappears completely, which shows that after the product is washed to remove the soluble reactant, relatively pure CdS is obtained. The a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com