A kind of method for producing hcl gas from chlorosilane raffinate

A chlorosilane residual liquid and gas technology, applied in the direction of chlorine/hydrogen chloride, etc., can solve the problems of difficult cleaning, caking at the bottom of the pool, pipeline blockage, etc., so as to reduce the generation of silicate radicals, reduce the processing pressure, and prevent the generation of silicate radicals. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

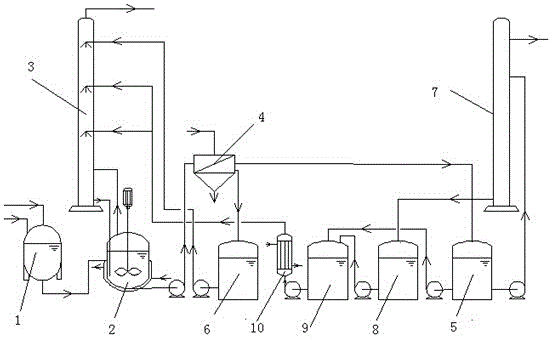

[0033] The method for producing HCl gas from a chlorosilane raffinate described in this embodiment is characterized in that it comprises the following steps:

[0034] The main component of the chlorosilane raffinate that this embodiment handles is 40% SiCl 4 , 40% SiHCl 3 , 15% SiH 2 Cl 2 , 5% HCl, a small amount of silicon powder and metal chloride, the treatment capacity is 0.5t / h.

[0035] (1) Transfer the chlorosilane raffinate that has been filtered to remove most of the silicon powder and metal chlorides to the raffinate storage tank 1, and use N 2Press the chlorosilane raffinate from the raffinate storage tank 1 to the stirred reactor 2 and the absorption liquid from the absorption tower 3 for hydrolysis reaction, the reaction residence time is 6 minutes, and the temperature of the stirred reactor 2 is controlled at 45-50°C.

[0036] (2) Use dilute hydrochloric acid to absorb the volatile gas produced by the stirred reactor 2 in the absorption tower 3, and the absor...

Embodiment 2

[0044] The method for producing HCl gas from a chlorosilane raffinate described in this embodiment is characterized in that it comprises the following steps:

[0045] The main component of the chlorosilane raffinate that this embodiment handles is 60% SiCl 4 , 30% SiHCl 3 , 9% SiH 2 Cl 2 , 1% HCl, a small amount of silicon powder and metal chloride, the processing capacity is 0.5t / h.

[0046] (1) Transfer the chlorosilane raffinate that has been filtered to remove most of the silicon powder and metal chlorides to the raffinate storage tank 1, and use N 2 Press the chlorosilane raffinate from the raffinate storage tank 1 to the stirred reactor 2 and the absorption liquid from the absorption tower 3 for hydrolysis reaction, the reaction residence time is 8 minutes, and the temperature of the stirred reactor 2 is controlled at 40~45°C.

[0047] (2) Use dilute hydrochloric acid to absorb the volatile gas produced by the stirring reactor 2 in the absorption tower 3, and the abs...

Embodiment 3

[0055] The method for producing HCl gas from a chlorosilane raffinate described in this embodiment is characterized in that it comprises the following steps:

[0056] The main component of the chlorosilane raffinate that this embodiment handles is 90% SiCl 4 , 5% SiHCl 3 , 4.5% SiH 2 Cl 2 , 0.5% HCl, a small amount of silicon powder and metal chloride, the treatment capacity is 0.5t / h.

[0057] (1) Transfer the chlorosilane raffinate that has been filtered to remove most of the silicon powder and metal chlorides to the raffinate storage tank 1, and use N 2 Press the chlorosilane raffinate from the raffinate storage tank 1 to the stirred reactor 2 and the absorption liquid from the absorption tower 3 for hydrolysis reaction, the reaction residence time is 10 minutes, and the temperature of the stirred reactor 2 is controlled at 35-40°C.

[0058] (2) Use dilute hydrochloric acid to absorb the volatile gas produced by the stirred reactor 2 in the absorption tower 3, and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com