Anti-explosion dust remover

A dust collector and dust box technology, applied in the field of machinery, can solve problems such as fire extinguishing, explosion, etc., and achieve the effects of saving time, increasing movement routes, and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

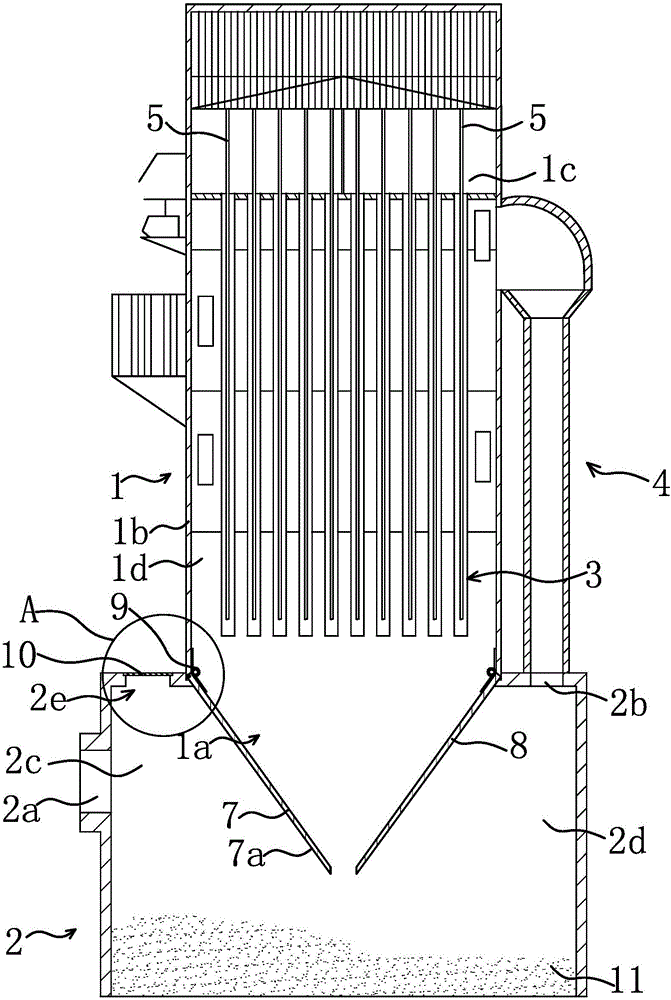

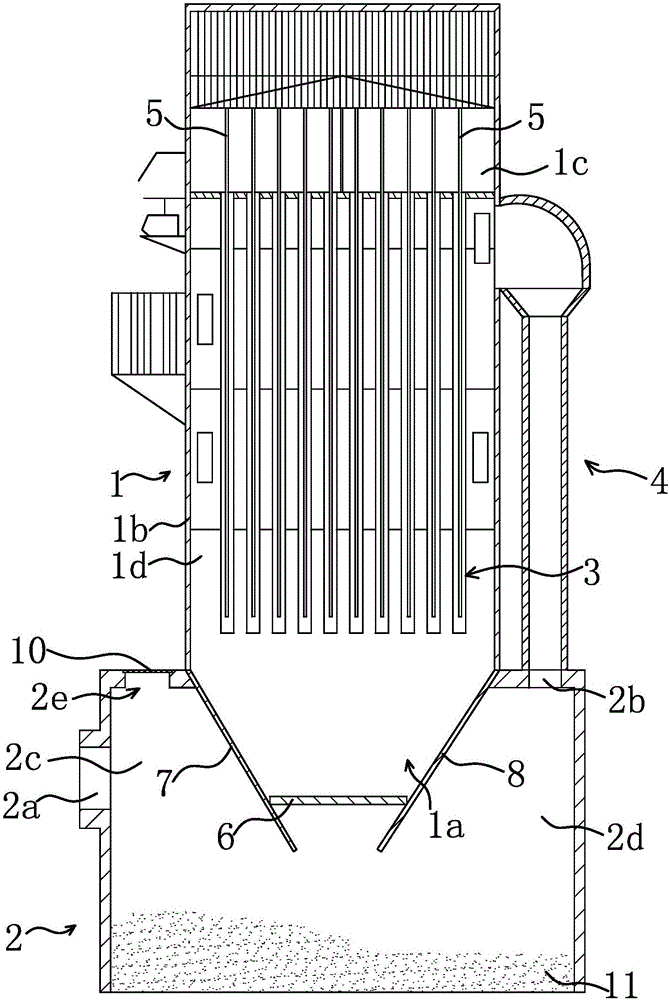

[0041] like figure 1 , Figure 4 As shown, an explosion-proof dust collector includes a dust removal box 1 and an ash storage box 2 located below the dust removal box 1. The dust removal box 1 is fixedly connected with the ash storage box 2. The dust removal box 1 includes a dust removal chamber 1d and a clean air chamber 1c. The cavity 1d is fixedly connected with a filter bag 3, the ash storage box 2 is provided with a primary air inlet 2a and a primary air outlet 2b that communicate with the inner cavity of the ash storage box 2, the dust collector is provided with an explosion-proof assembly, the explosion-proof assembly Including a first explosion-proof baffle 7, the first explosion-proof baffle 7 is located in the ash storage box 2 and can block the dust 11 entering from the primary air inlet 2a and the sparks entrained in the dust 11, and the first explosion-proof baffle 7 makes the ash storage box. 2. The upper part of the inner cavity is divided into an air inlet cha...

Embodiment 2

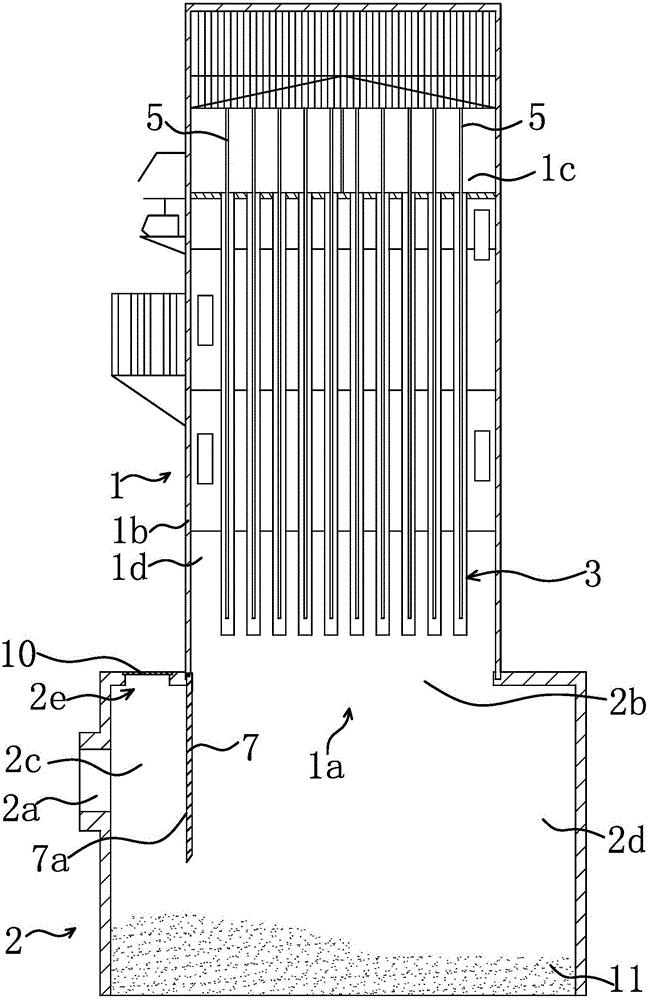

[0051] like figure 2 As shown, the structure and principle of this embodiment are basically the same as those of the first embodiment, and the difference is that the second explosion-proof baffle 8 is not provided in this embodiment, and the first explosion-proof baffle 7 and the explosion-venting plate 10 are only provided To achieve fire-fighting and explosion-proof. The dust 11 from the air inlet chamber 2c to the air outlet chamber 2d can directly enter the dust removal box 1 through the dust collection channel 1a for dust removal.

Embodiment 3

[0053] like Figure 7 As shown, the structure and principle of this embodiment are basically the same as those of the first embodiment, and the difference is that the control element in this embodiment is a screw conveyor 14, and a screw conveyor is provided outside the dust box 1 for driving the screw conveyor The motor 15 of 14, due to the poor working environment in the dust box 1, if the motor 15 is installed in this, it is easy to cause damage, so the motor 15 is installed at the bottom of the outside of the dust box 1, between the first explosion-proof baffle 7 and the second A screw conveyor 14 is installed between the ash collecting channel 1a formed by the explosion-proof baffle 8 and the motor 15, and the dust 11 at the bottom of the ash storage box 2 is transported to the outside of the box through the screw conveyor 14 for centralized recovery. For example, the ash outlet 14a of the screw conveyor 14 is located outside the dust box 1, and the dust box 16 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com