Plug-in assembly

A component and plug-in technology, which is applied in the direction of electrical components, two-part connection devices, parts of connection devices, etc., can solve problems such as complex production process and complex structure, and achieve the effect of simple process, small size and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

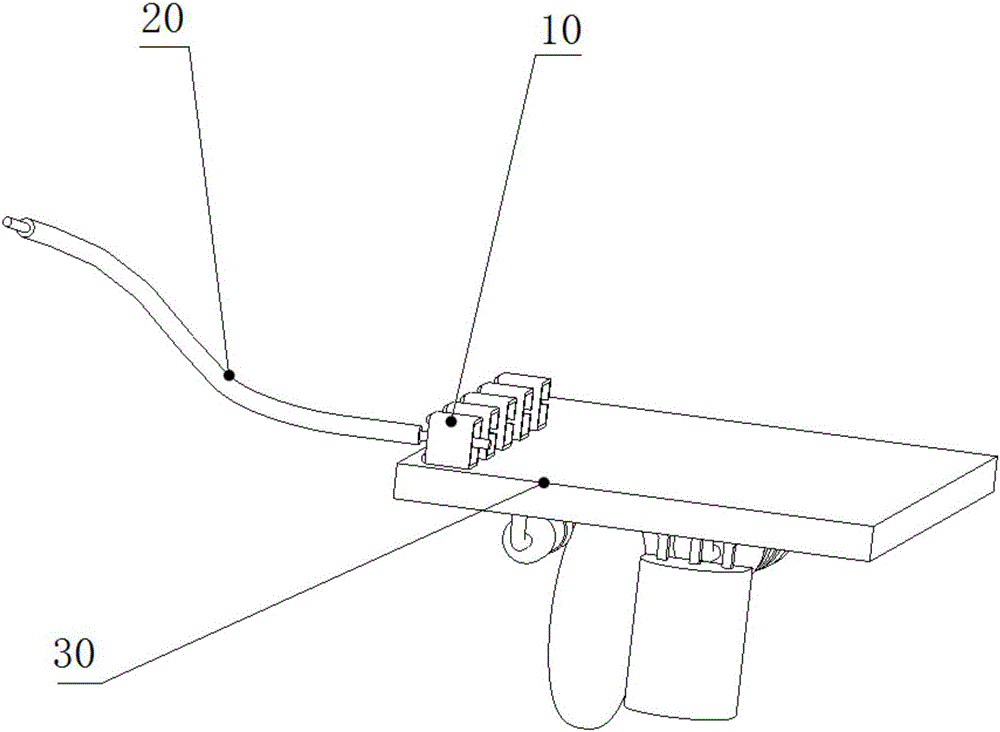

[0038] This embodiment provides a plug-in component, refer to figure 1 with figure 2 , the plug-in assembly of this embodiment includes a lead wire 20 and a plug-in female head 10 made of conductive material, and an elastic card slot 12 for inserting the lead wire 20 is arranged on the plug-in female head 10, and the elastic card slot 12 is placed on the plug-in female head 10. When the lead wire 20 is inserted, it is pressed by the lead wire 20 to be elastically deformed, and the elastic locking groove 12 that is squeezed and elastically deformed clamps the lead wire 20 by elastic restoring force.

[0039] The above technical solution is the core technical solution of this embodiment. The plug-in female head 10 of this embodiment can directly cooperate with the lead wire 20, and the elastic locking groove 12 of the plug-in female head 10 is elastically deformed when the lead wire is inserted, so that Clamp the lead wire 20, therefore, the plug-in assembly of this embodiment...

no. 2 approach

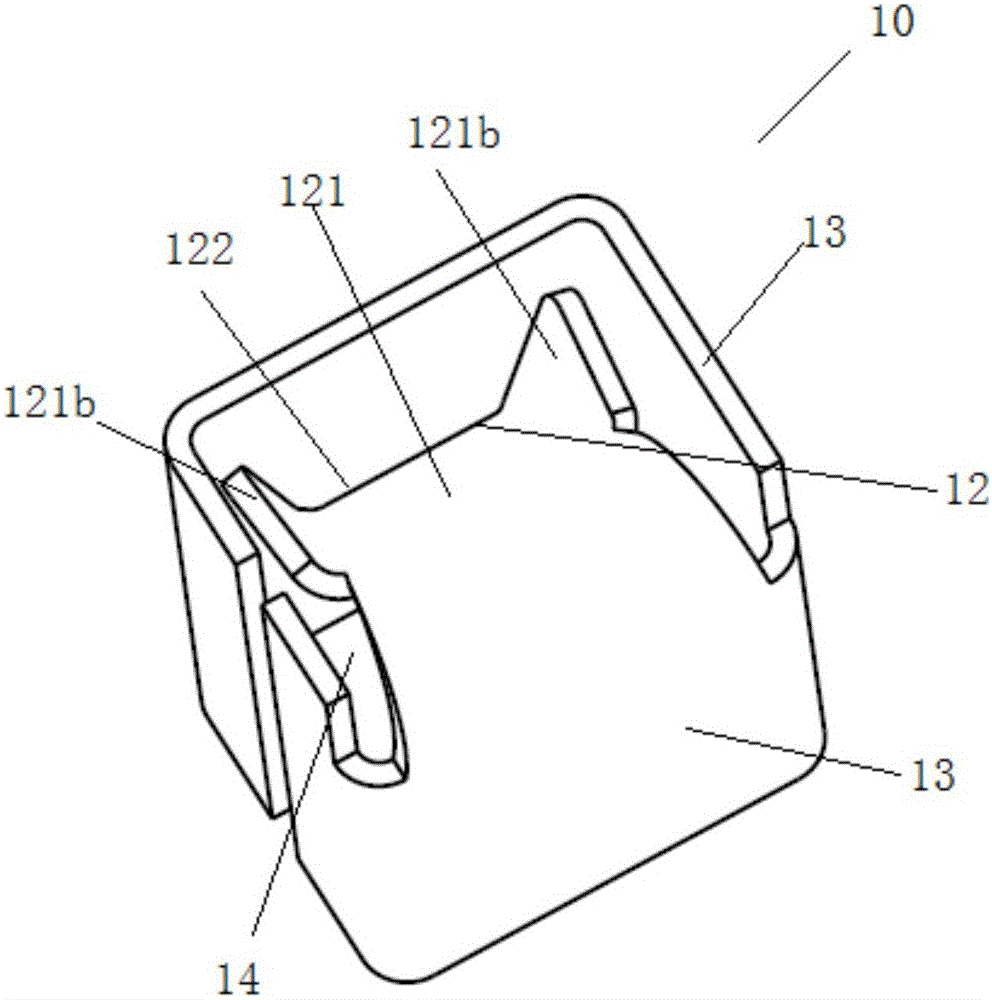

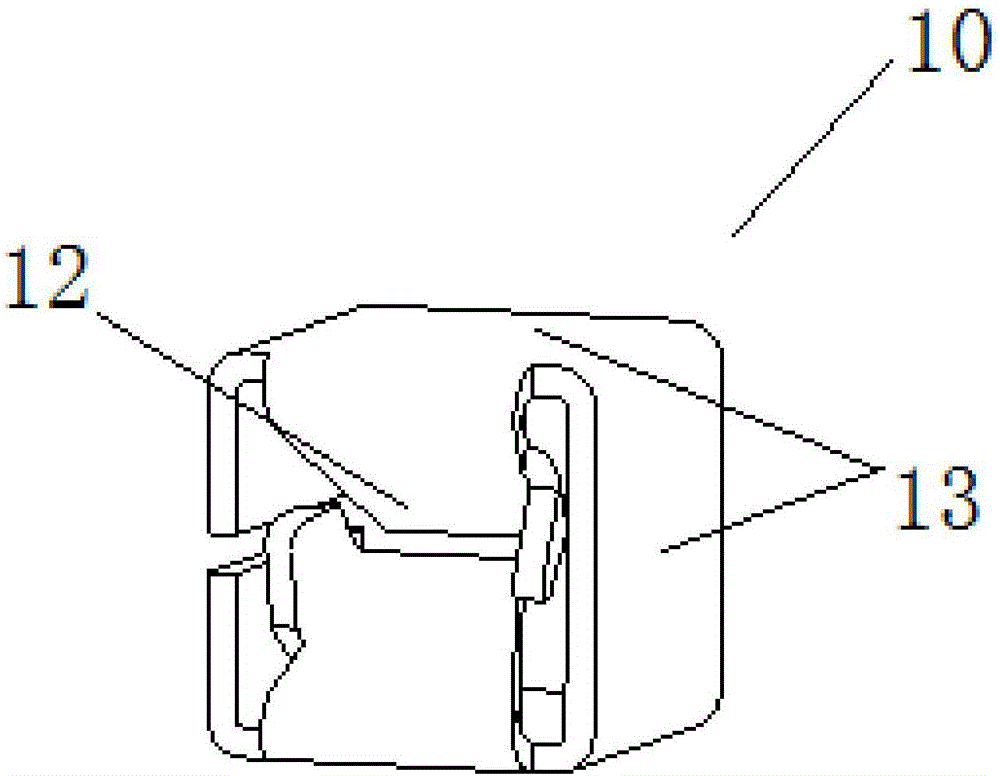

[0050] Such as Figure 3-Figure 5 As shown, this embodiment provides a plug-in component. The difference between the plug-in component in this embodiment and the plug-in component in the first embodiment is:

[0051] In this embodiment, the elastic slot 12 of the plug-in female head 10 is designed with double clamping arms, specifically: the plug-in female head 10 is in the shape of a square tube, including a tube wall 13 and a wall surrounded by the tube wall 13. Cavity 14; the elastic slot 12 includes clamping arms 121 that are formed on the front edges of the corresponding two cylinder walls 13, extend toward the insertion direction of the lead wire 20 in the cavity 14, and are obliquely close to each other, The clamping arm 121 is made of the same material as the clamping arm 121 of the first embodiment, preferably integrally formed with the cylinder wall forming it, and a gap for the lead wire 20 to be inserted is formed between the two clamping arms 121 122 , the width ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com