Method for preparing hydrophobic SERS substrate by using silk-screen printing technology

A screen printing, hydrophobic technology, applied in Raman scattering, material excitation analysis, etc., can solve the problems of lack of serial comparability, complicated preparation methods, uncontrollable roughness, etc., to achieve rapid testing, low price, and high sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Mix 0.12g of siloxane-modified epoxy resin, 0.87g of nano-silver particles and 5mL of diethylene glycol ether acetate, and then add 0.01g of 5-decyne-4,7-diol-479- Tetramethyl (DDTM) dispersant, magnetically stirred until uniformly mixed to obtain a slurry.

[0035] The paste configured above was screen printed with 420 mesh polyester. Place the pretreated ITO film on a flat substrate, place the screen flat on the ITO film, and drop an appropriate amount of slurry on the surface of the screen. The amount of slurry can be quickly scraped from the surface of the screen with a soft scraper. After that, a thin film was obtained.

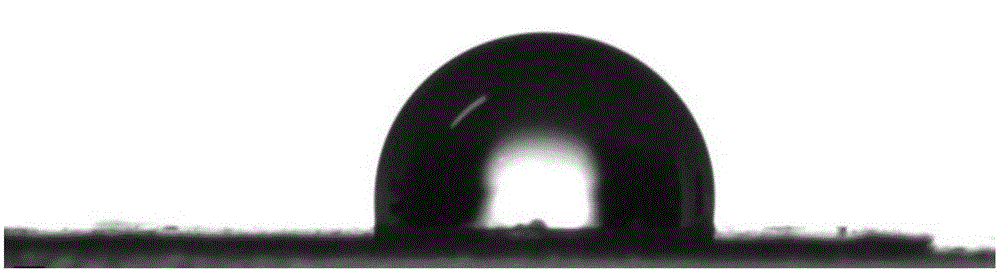

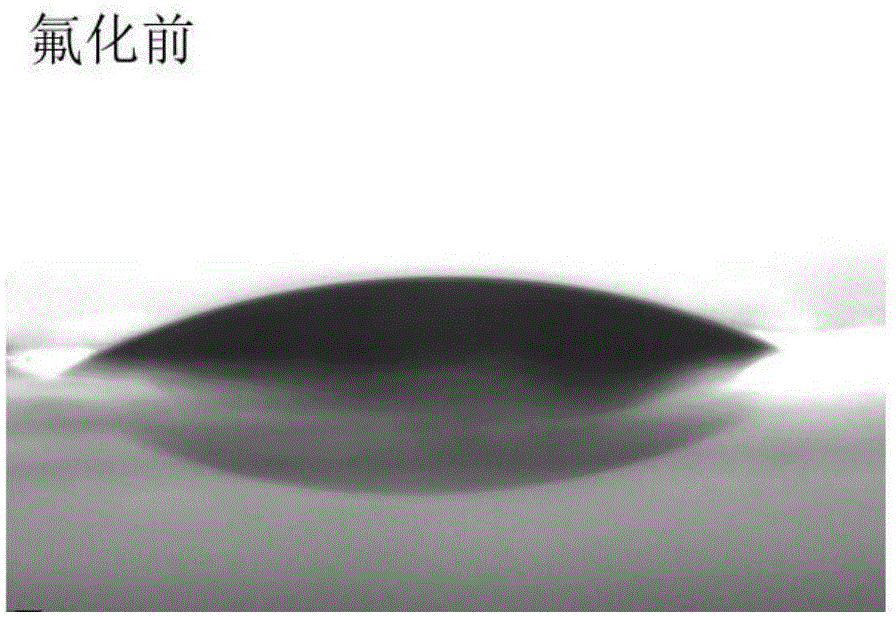

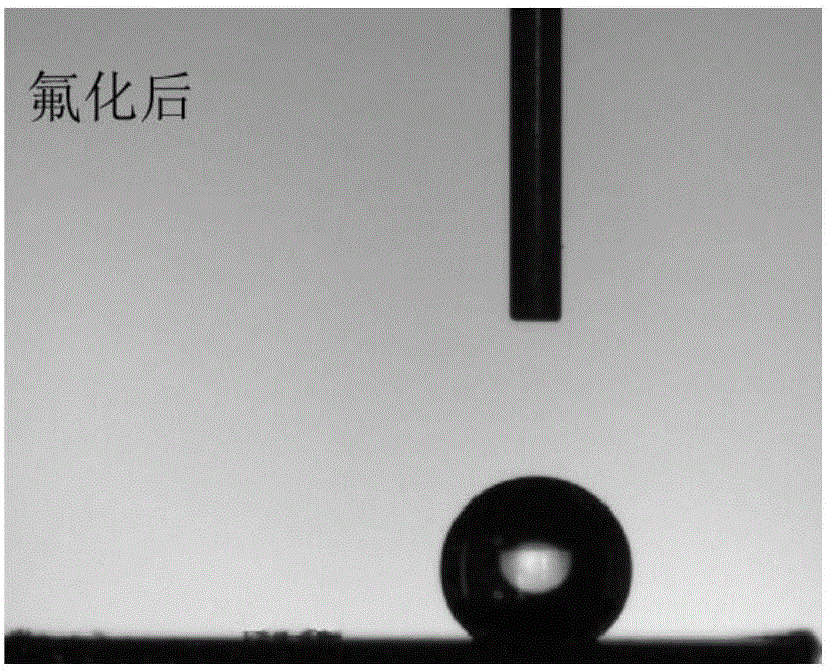

[0036] Place it horizontally at room temperature for 10 minutes, then bake and solidify at 150°C for 30 minutes. The surface was cleaned with methyl ketone to obtain a hydrophobic SERS substrate, the SEM of which is shown in image 3 , the nano-silver particles are uniformly distributed and densely arranged, and the contact angle of water dropl...

Embodiment 2

[0038] Mix 0.12g of siloxane-modified epoxy resin, 0.87g of nano-gold particles and 5mL of diethylene glycol ether acetate evenly, then add 0.01g of DDTM dispersant, stir magnetically until uniformly mixed, and use it as a slurry. The paste configured above was screen printed with 420 mesh polyester. Place the pretreated ITO film on a flat substrate, place the screen flat on the ITO film, and drop an appropriate amount of slurry on the surface of the screen. The amount of slurry can be quickly scraped from the surface of the screen with a soft scraper. After that, a thin film was obtained. Place horizontally at room temperature for 10 minutes, then bake at 150°C for 30 minutes. Clean the surface with methyl ketone to obtain a film layer that is the hydrophobic SERS substrate.

Embodiment 3

[0040]Mix 0.12g of siloxane-modified epoxy resin, 0.87g of Au / Ag core-shell structure nano-metal particles and 5mL of diethylene glycol ethyl ether acetate, then add 0.01g of DDTM dispersant, magnetically stir until mixed Uniformly, as a slurry. The paste configured above was screen printed with 420 mesh polyester. Place the pre-shrunk ITO film (preheated at 150°C for 60 minutes) on a flat substrate, place the screen flat on the ITO film, and drop an appropriate amount of slurry on the surface of the screen. The quality scraper quickly scrapes across the surface of the screen to obtain a thin film. Place horizontally at room temperature for 10 minutes, then bake at 150°C for 30 minutes. Clean the surface with methyl ketone to obtain a film layer that is the hydrophobic SERS substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com