A High Thermal Stability Ion Thruster Screen Barrel

A technology of ion thruster and screen cylinder, which is applied in the field of ion propulsion technology and thermal control, can solve the influence of discharge chamber stability and beam straightness, the distance between screen grid cylinder and anode cylinder is reduced, and the linear expansion coefficient The uncontrollability of the screen grid tube and other issues can be achieved to reduce the temperature, improve the heat dissipation capacity, and reduce the risk of structural failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0029] The present invention mainly starts with structural reinforcement, while considering positioning and thermal stress release, and adopts thermal control measures such as surface coating, which greatly improves the thermal stability of the grid cylinder and can meet the use requirements of high-power ion thrusters.

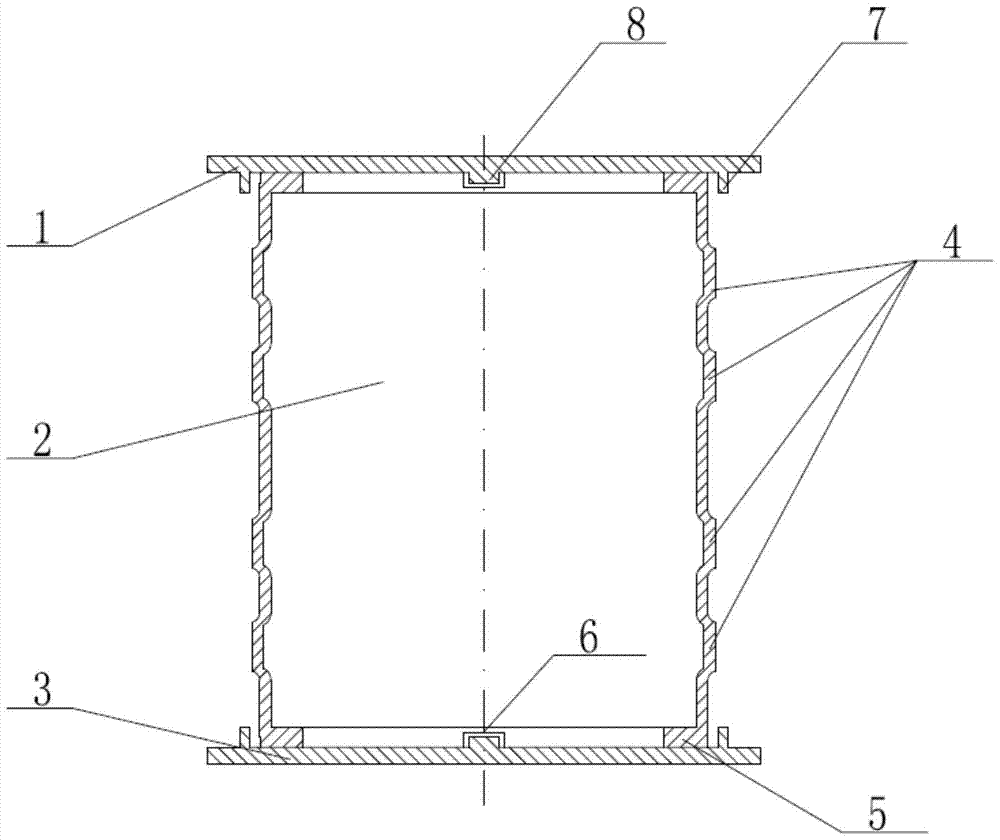

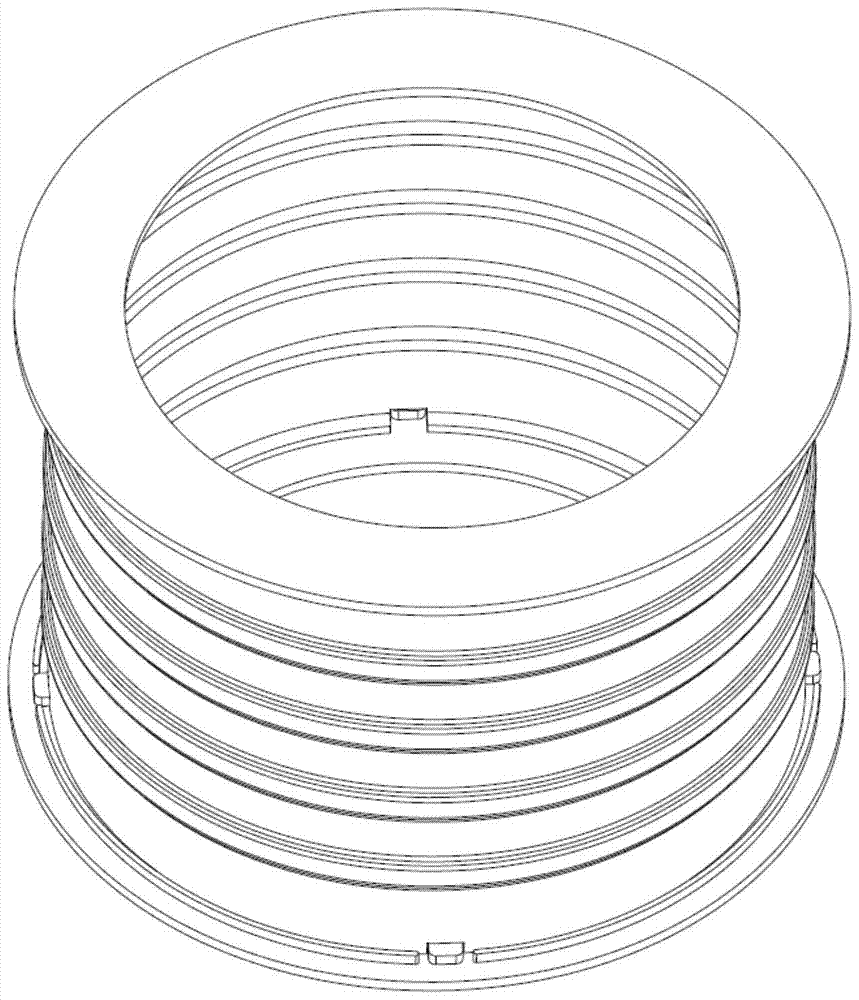

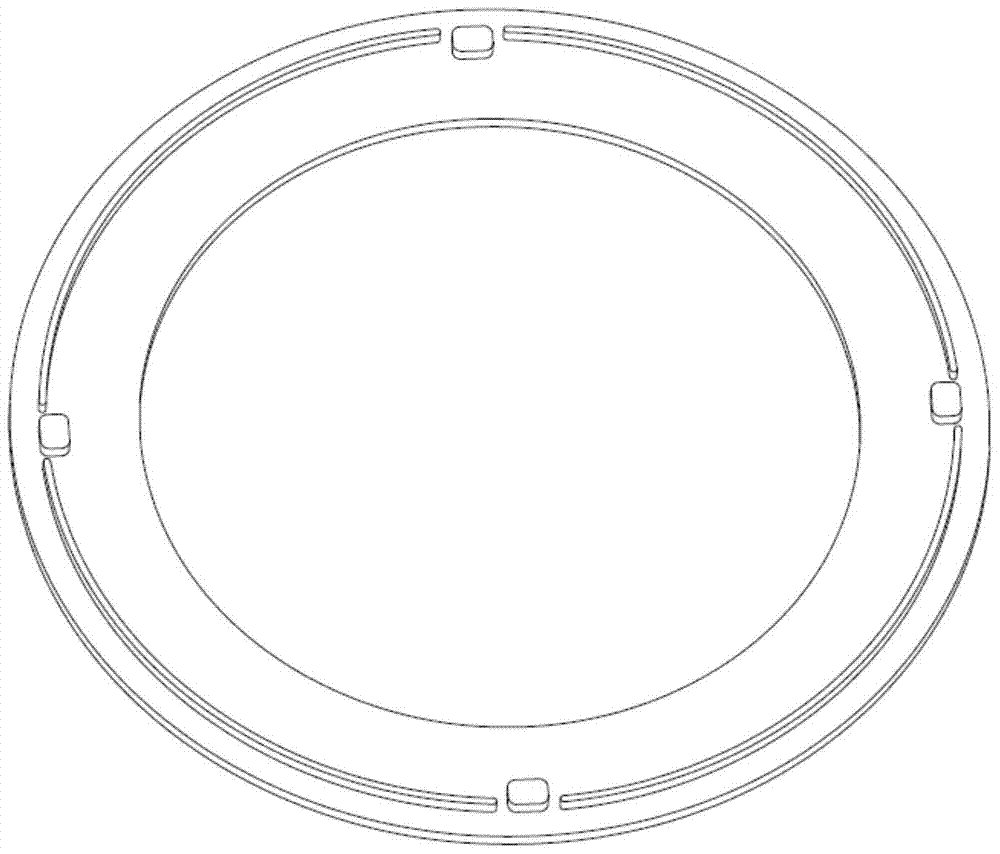

[0030] The highly thermally stable ion thruster screen grid cylinder structure of the embodiment of the present invention is as follows figure 1 As shown, it includes a screen cylinder body 2 , and an upper fixing structure 1 and a lower fixing structure 3 installed on both ends of the screen cylinder body 2 . Wherein, the fixed structure 1 and the lower fixed structure 3 are annular structures, such as figure 2 shown.

[0031] The screen cylinder body 2 adopts a cylindrical thin-walled structure, and outwardly protruding ribs 4 with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com