Truss manufacturing system and manufacturing process of escalator or automatic sidewalk

A technology of moving walks and escalators, applied in the field of truss systems, can solve problems such as load-bearing structure devices, and achieve good welding posture and position effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

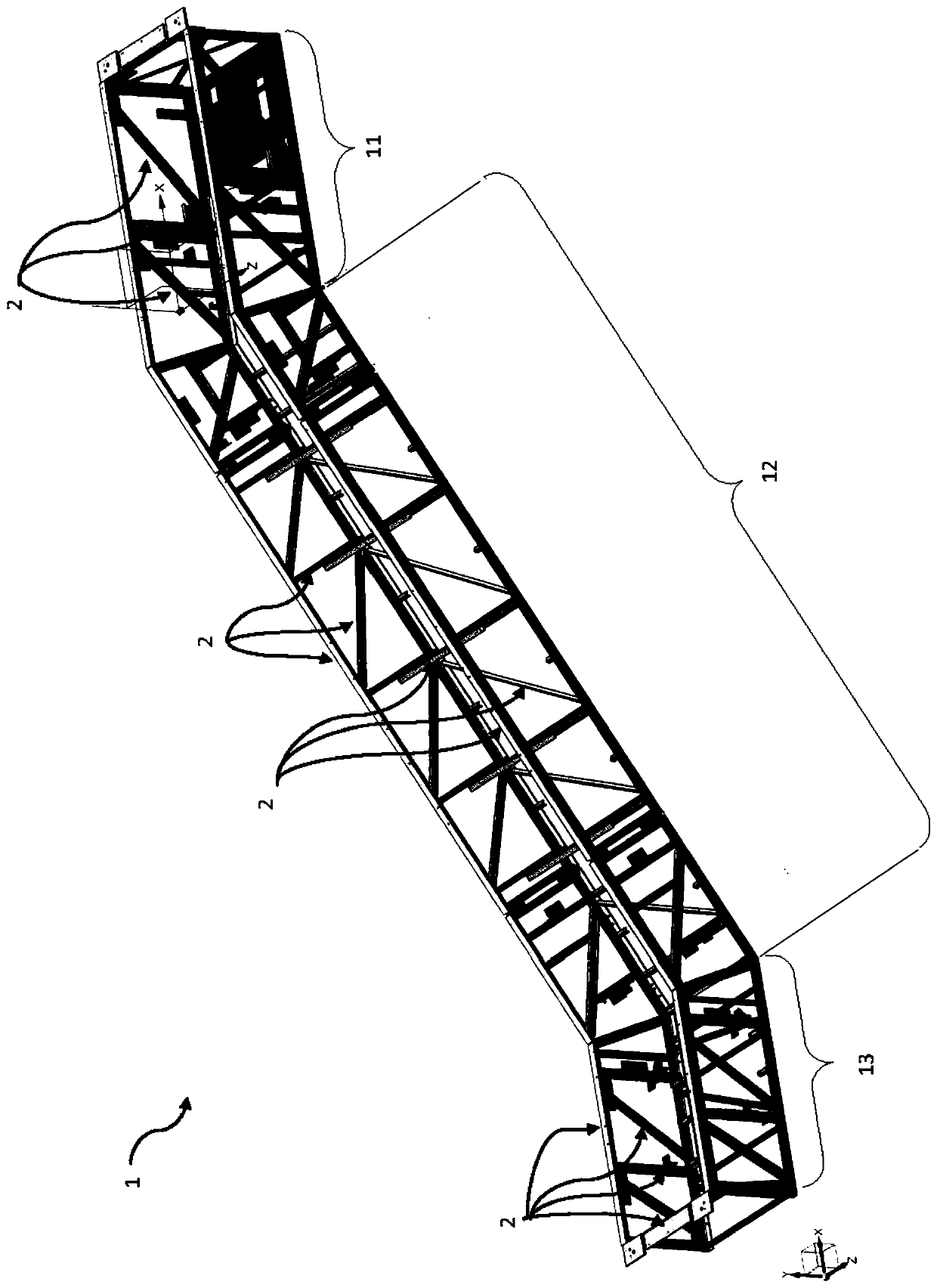

[0076] In the manufacturing system of the truss of the escalator or moving walk provided by the present invention, the truss 1 includes an upper part 11, a middle part 12 and a lower part 13, and the upper part 11, the middle part 12 and the lower part 13 are respectively composed of Components of 2 are connected to each other, such as figure 1 shown.

[0077] for manufacturing figure 1 The truss manufacturing system shown includes a first workstation, a second workstation, and a third workstation arranged in sequence.

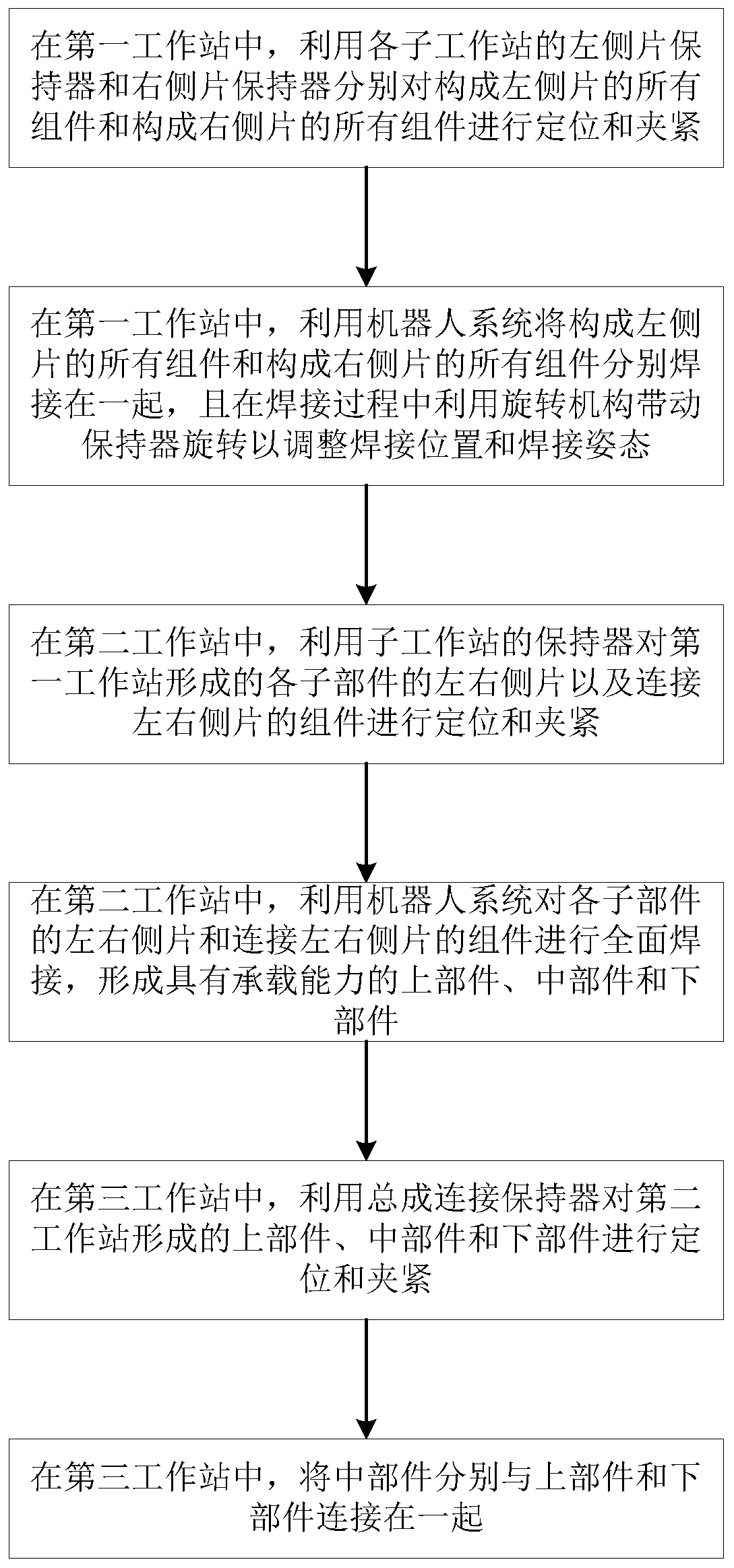

[0078] The first workstation includes at least three sub-workstations: the upper part side piece workstation, the middle part side piece workstation and the lower part side piece workstation. Side pieces, each sub-workstation has a left piece holder for holding the components that make up the left piece, a right piece holder for holding The components that make up the right side piece, the robot system is used to weld the components separately to form the l...

no. 2 example

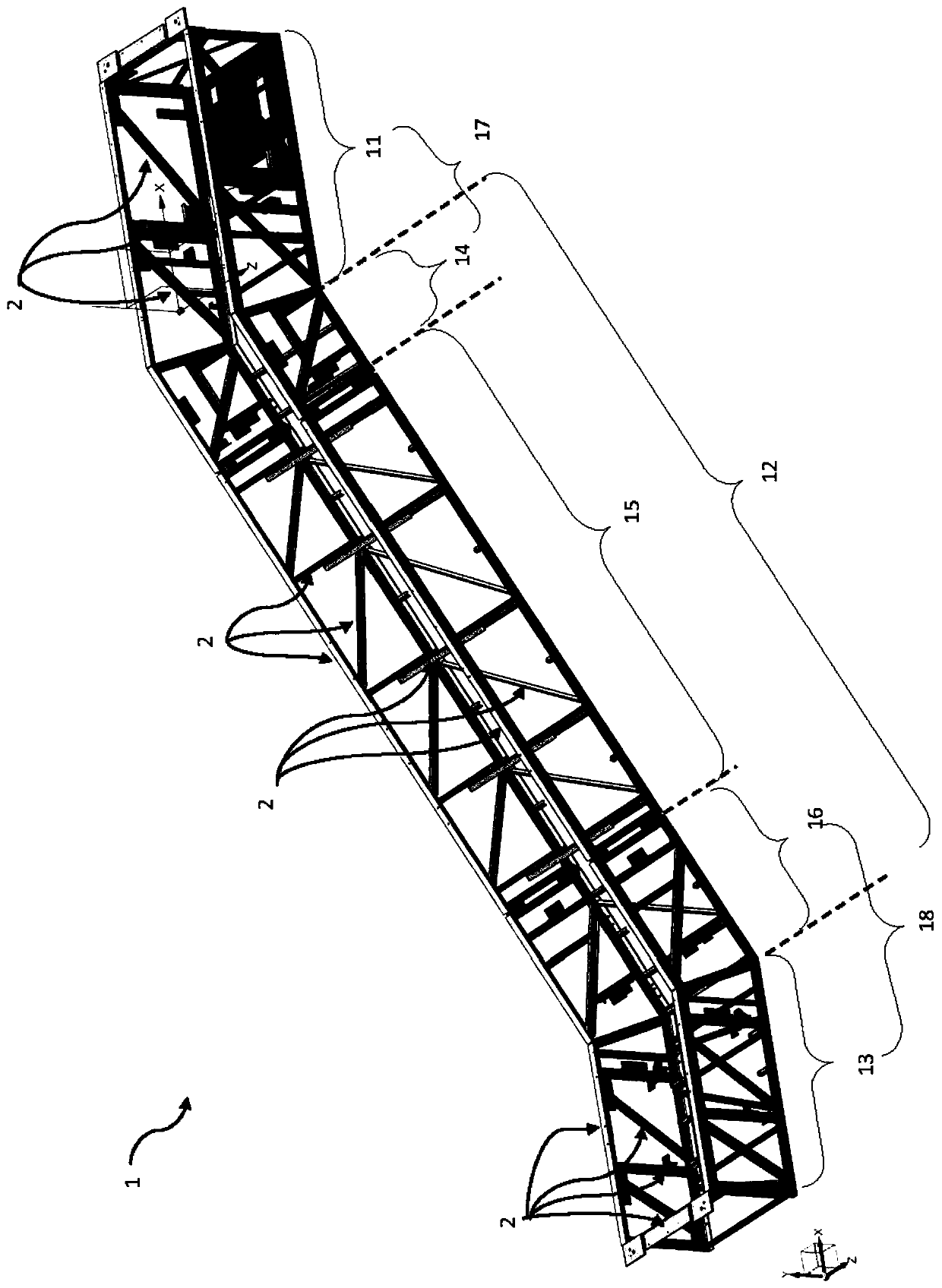

[0107] In the truss manufacturing system of an escalator or moving walk provided by the present invention, the truss 1 includes an upper part subassembly 17, a middle part subassembly 15 and a lower part subassembly 18, and the upper part subassembly 17, The small assembly 15 of the middle part and the small assembly 18 of the lower part are formed by interconnecting the components 2 with carrying capacity respectively, and the small assembly 17 of the upper part includes the upper part 11 and the first connecting part 14 and the first connecting part 14 and An included angle is formed between the upper parts 11, the lower part small assembly 18 includes the lower part 13 and the second connecting part 16 and an included angle is formed between the second connecting part 16 and the lower part 13, and the middle Parts subassembly 15 is respectively connected with the first connection part 14 and the second connection part 16, such as image 3 shown.

[0108] for manufacturing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com