Nylon zipper tooth counting mechanism for zipper fixed-dimension tooth remover

A technology of sizing and removing teeth and zipper chains, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the size difference and error, ranging from 1-2 pieces, as many as 3-4 pieces, affecting clothing Aesthetics and other issues, to achieve the same number of teeth, improve quality, and accurate size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

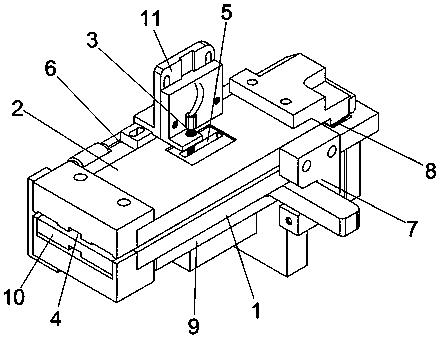

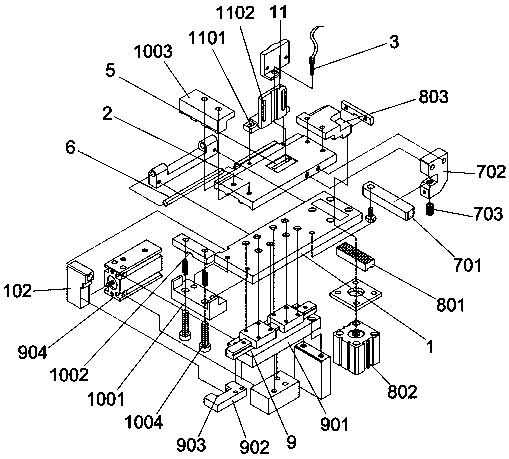

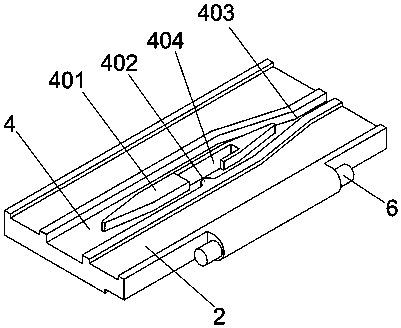

[0026] Such as Figure 1-4 As shown, a nylon zipper tooth counting mechanism of a zipper fixed size tooth removal machine includes a bottom plate 1, an upper cover plate 2 and a tooth counting device 3, and a chain guide groove 4 is formed between the upper cover plate 2 and the bottom plate 1, The chain guide groove 4 is provided with a divided tooth part, and the divided tooth part is used to temporarily increase the interval between the chain teeth 1501 of the zipper chain 15. The upper cover plate 2 has an observation port 5, and the observation port 5 is located at the branch. The upper position of the tooth part, the said digital tooth device 3 is arranged above the viewing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com