Automatic putting device for mechanical parts

A technology of mechanical parts and delivery devices, which is applied in the direction of conveyor objects, packaging, loading/unloading, etc., can solve the problems of increasing the manufacturing cost of automatic delivery structures, many electronic components and transmission structures, and increasing the probability of device failure, etc., to achieve increased Large elasticity, low maintenance difficulty, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

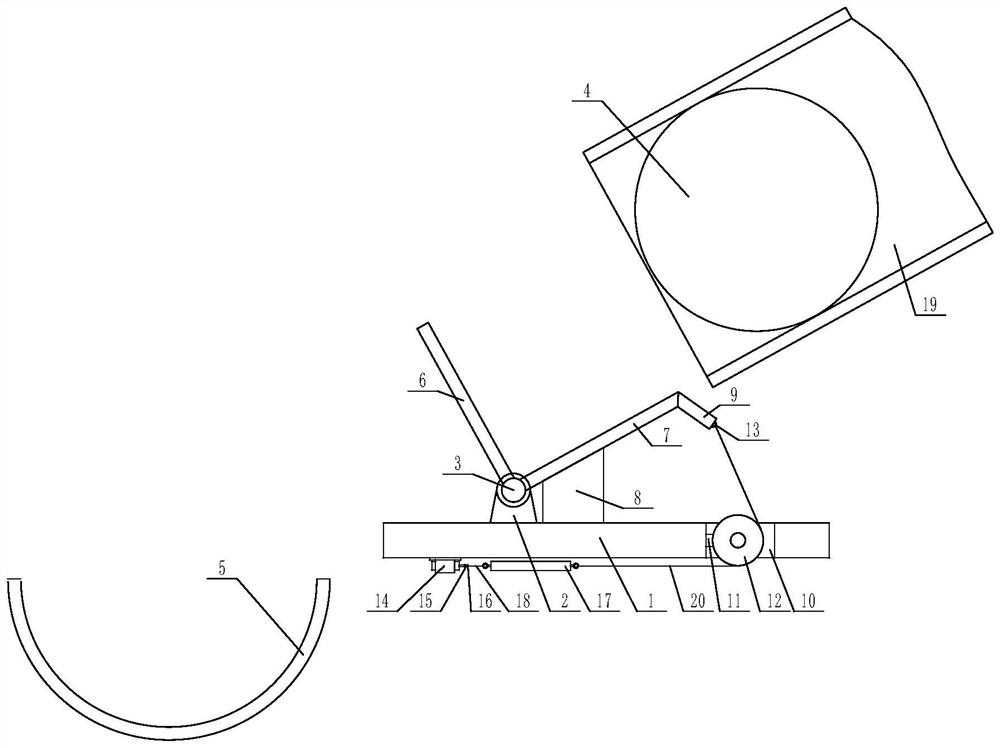

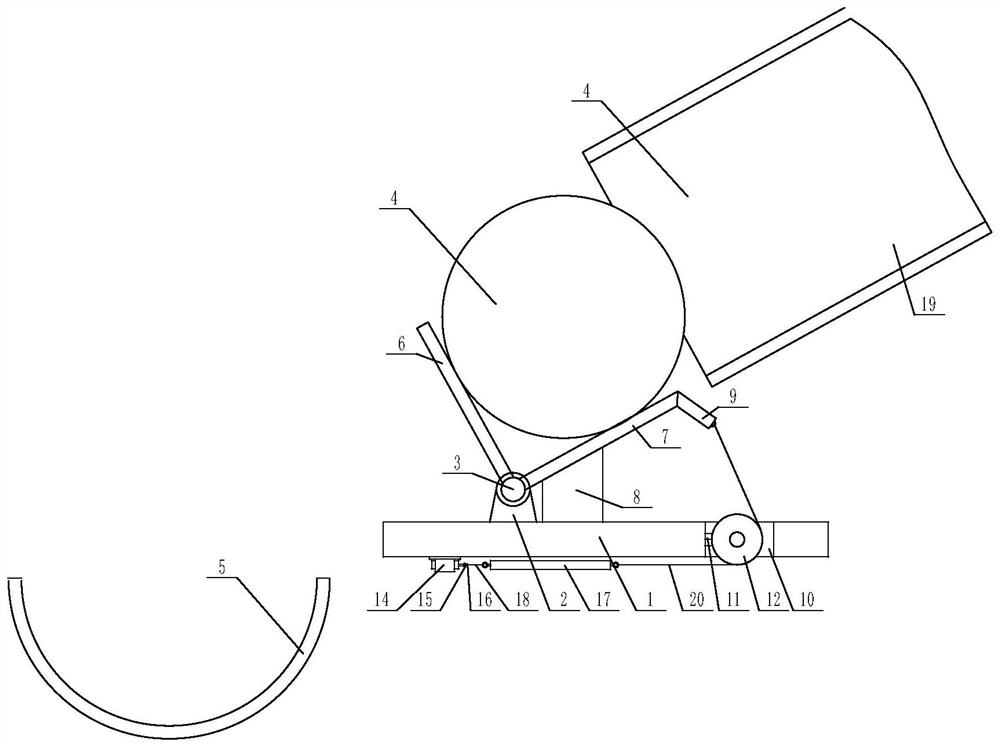

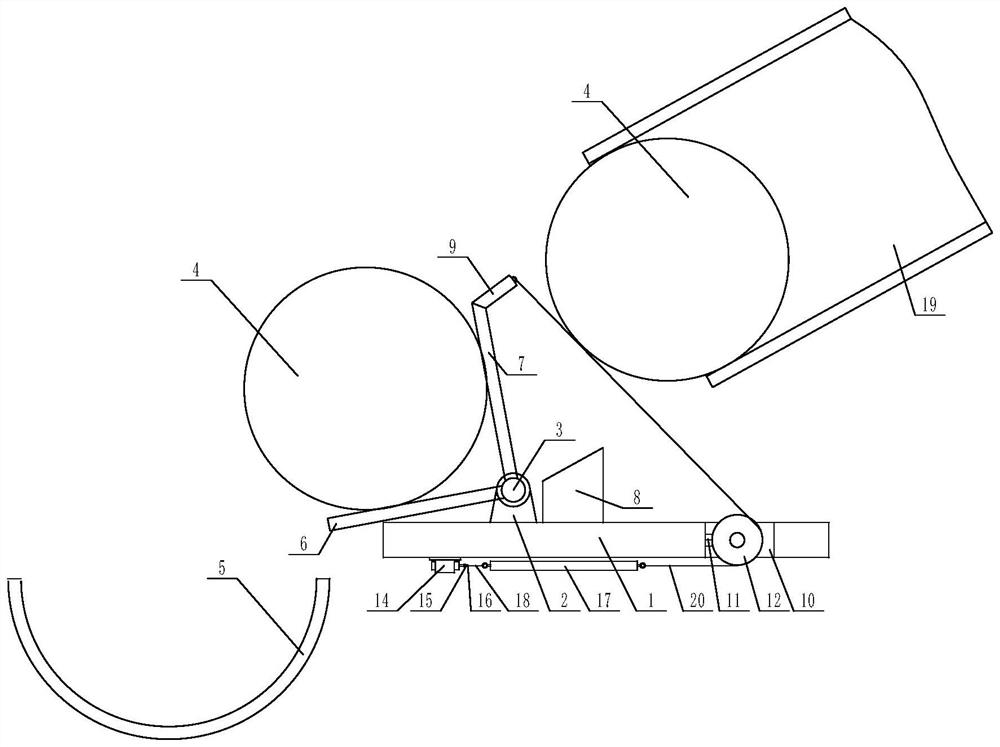

[0026] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 shown;

[0027] The inventive point of the present application is that the limit plate one 6 and the limit plate two 7 are fixedly installed on the rotating shaft, the length direction of the limit plate one and the limit plate two is the same, the limit plate one and the limit plate The angle between the two is greater than sixty degrees and less than one hundred and twenty degrees. The length of the first limit plate is the same as that of the second limit plate and matches the length of the rotating shaft. The first limit plate and the limit plate Plate two can follow the rotation of the shaft, and the upper surface of the base plate is fixedly installed with a block 8, which is located between the feeding channels of the shaft. The shape of the block is a right-angled trapezoid, and the slope of the block faces Above, the slope of the stopper is low on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com