Working face integrated support and mining method for steep seam

A mining method and technology of working face, which are applied in ground mining, mine roof support, mining equipment and other directions, can solve the problems of low degree of mechanization, poor stability of support, low mining efficiency, etc., and achieve simplified process flow, increased operating rate, mining Efficiency-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

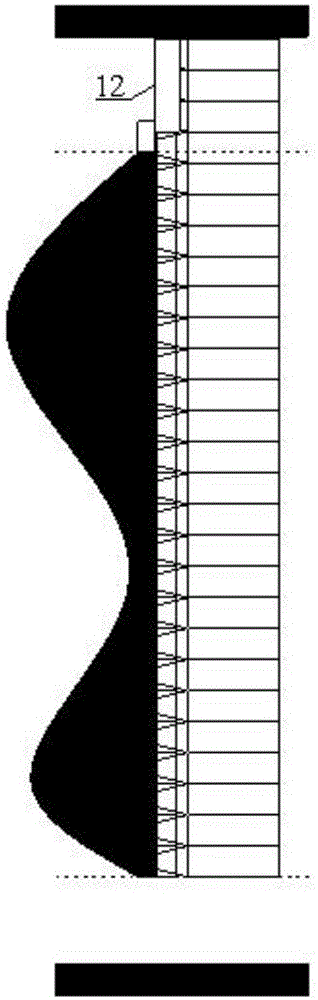

[0048] Embodiment: The specific moving process of the working face of this mining method is as follows, wherein, Fig. 3(a), Fig. 3(b), Fig. 3(c), Fig. 3(d), Fig. 3(e), Fig. 3(f ), Fig. 3 (g) is the concrete moving engineering schematic diagram of this mining method. Figure 3(a), 1 in the working plane # The hydraulic support and the loader 17 in the transportation lane 15 at the lower end are connected to each other as a whole through the push jacks 10 between the support bases 4. Before the frame is moved, the mutual push jacks 10 are in a contracted state; Fig. 3(b) coal shearer 12 When cleaning the floating coal upwards, the reloading machine 17 moves forward by a cut depth by its own traveling mechanism, and the reloading machine 17 and 1 # The push jack 10 between the hydraulic supports is stretched out; Fig. 3 (c) after the loader 17 moves to the designated position and stabilizes, 1 # The support strut is unloaded, and the loader 17 and 1 # The push jack 10 between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com