Bolt quenching production line

A production line and bolt technology, applied in the field of heat treatment equipment, can solve problems such as low production efficiency, unstable product quality, and inability to meet large-scale production, and achieve the effects of improving production efficiency, saving manpower and material resources, and a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the present invention will be further described to facilitate the understanding of technical personnel.

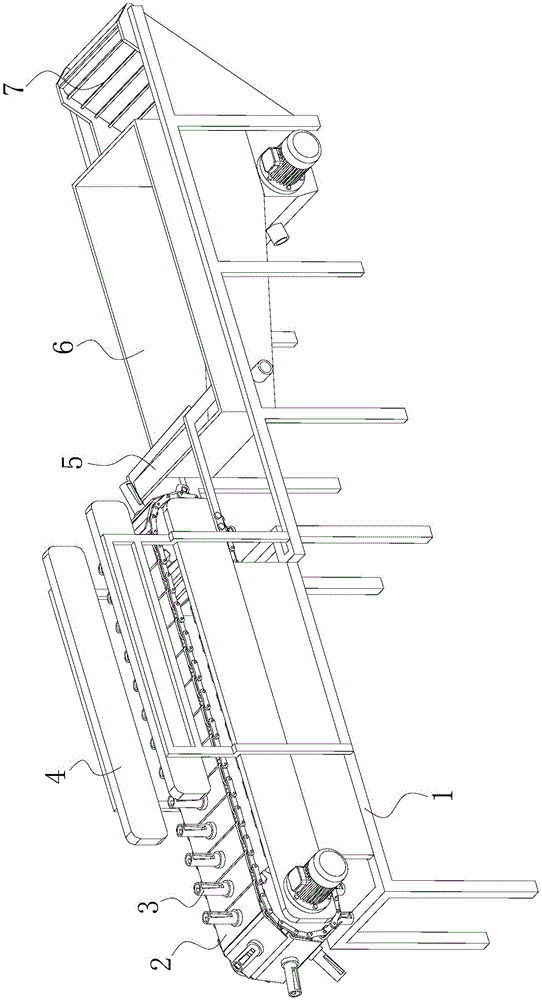

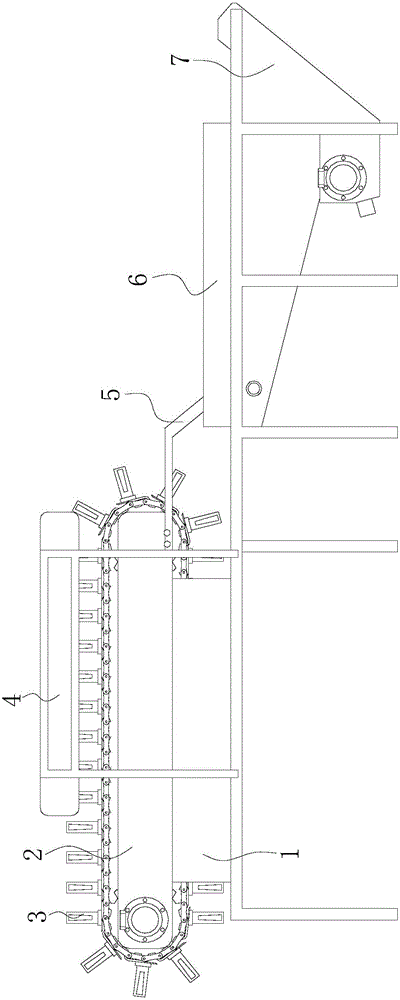

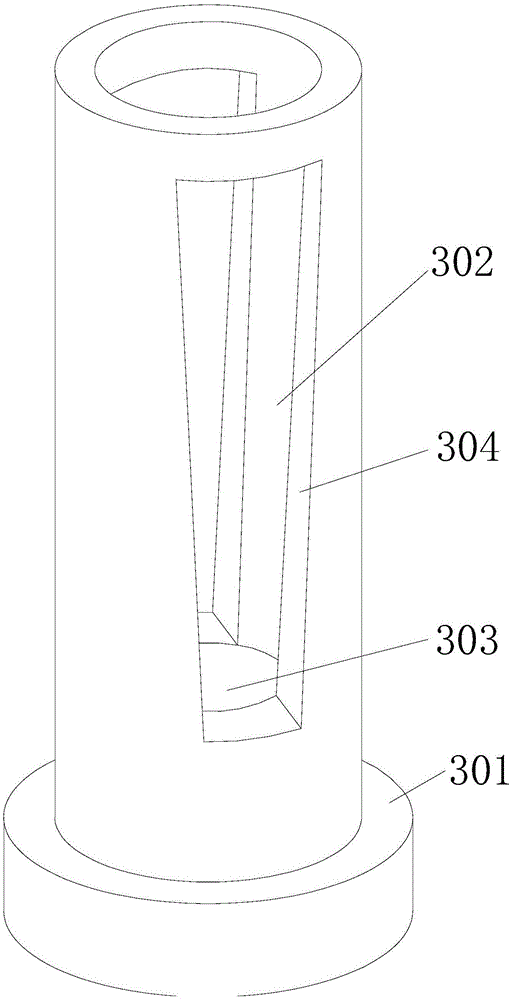

[0018] Such as Figure 1 to Figure 2 As shown, a bolt quenching production line includes a support frame 1, a conveyor belt 2 is installed on the upper end of the support frame 1, a bolt feeder is externally connected to the left end of the conveyor belt 2, and bolt fixing seats 3 are evenly installed on the transmission belt. Heating devices 4 are provided at the front and rear of the conveyor belt, and the heating devices 4 are installed on the support frame 1. The right end of the conveyor belt 2 is fixed with a stripping plate 5 through bolt connection, and the stripping plate 5 is inclined. Set, the bolt slides down thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com