Thermal insulation functional coating for exterior walls

A technology of thermal insulation and functional coatings, applied in coatings and other directions, can solve poor performances such as weather resistance, water resistance, alkali resistance, erosion resistance, elasticity, stability, etc., and poor thermal insulation effect of external wall thermal insulation coatings Ideal, poor protection ability and other problems, to achieve the effect of excellent thermal insulation performance, simple construction and short drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

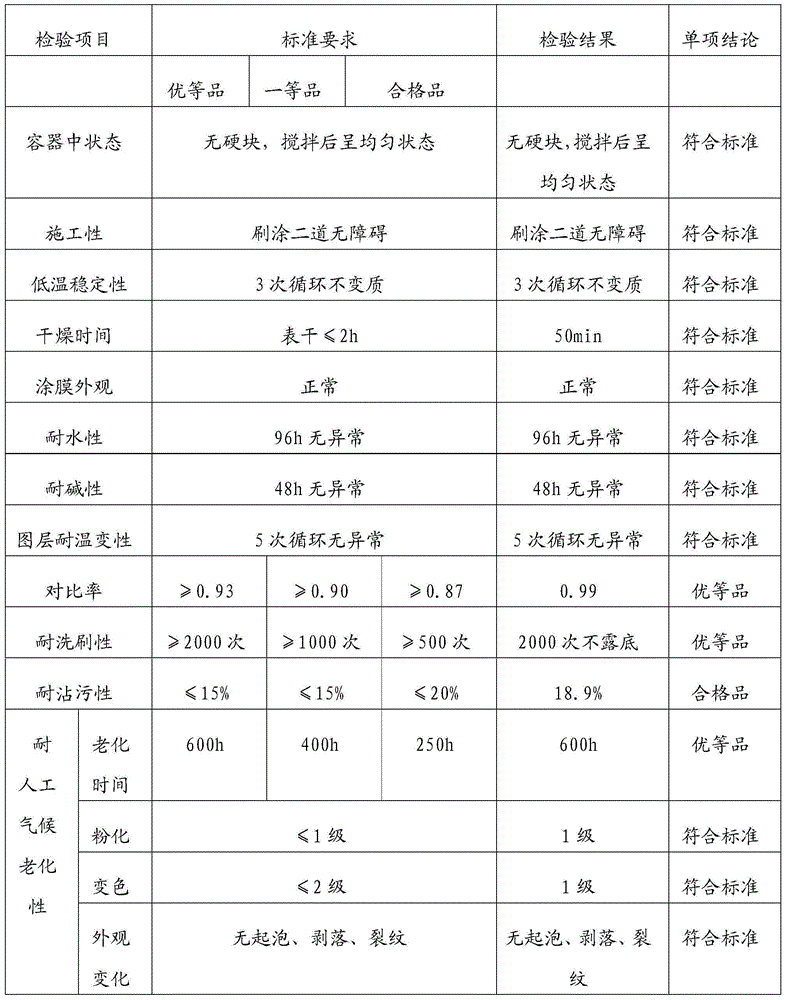

Examples

Embodiment 1

[0024] This embodiment provides a thermal insulation functional coating for exterior walls, including 100 parts by weight of deionized water, 1 part of hydroxyethyl cellulose with a molecular weight of 30,000, 0.3 parts of H436 wetting agent, 2-amino - 1.6 parts of 2-methyl-1-propanol (AMP-96) additive, 3 parts of WP-5040 dispersant, 3 parts of SPA-202 defoamer, 8 parts of propylene glycol, 20 parts of alcohol ester-12 film-forming aid Parts, 60 parts of rutile titanium powder R-215 colorant, 20 parts of heavy calcium carbonate 800 colorant, 20 parts of kaolin 1250 colorant, 80 parts of mica powder 1250 filler, containing silicon dioxide and aluminum oxide and the fineness is 40 parts of 600-mesh PM2.5 dust nano-beads, 460 parts of GK-996 styrene-acrylic emulsion, 0.7 parts of YN-215 preservative, 45 parts of ATW-2000 aqueous solution, 45 parts of ATW-60 aqueous solution, 2-amino-2 - 0.5 parts of methyl-1-propanol (AMP-95); wherein in the aqueous solution of ATW-2000 and the a...

Embodiment 2

[0032] This embodiment provides a thermal insulation functional coating for exterior walls, including 360 parts by weight of deionized water, 0.5 parts of hydroxyethyl cellulose with a molecular weight of 30,000, 1.7 parts of BZ201 wetting agent, 2-amino - 0.4 parts of 2-methyl-1-propanol (AMP-96) additive, 13 parts of BZ401 dispersant, 1 part of SPA-202 defoamer, 32 parts of propylene glycol, 8 parts of alcohol ester-12 film-forming aid, 240 parts of rutile titanium powder R-215 coloring agent, 80 parts of heavy calcium carbonate 800 coloring agent, 80 parts of kaolin 1250 coloring agent, 20 parts of glass flake filler, containing silicon dioxide and aluminum oxide with a fineness of 1000 mesh PM2 .5 260 parts of dust nano-beads, 100 parts of GK-996 styrene-acrylic emulsion, 3.3 parts of YN-215 preservative, 22.5 parts of ATW-2000 aqueous solution, 7.5 parts of ATW-60 aqueous solution, 2-amino-2-methyl - 1.5 parts of 1-propanol (AMP-95); wherein in the aqueous solution of ATW...

Embodiment 3

[0040] This embodiment provides a thermal insulation functional coating for exterior walls, including 230 parts by weight of deionized water, 0.75 parts of hydroxyethyl cellulose with a molecular weight of 30,000, 1 part of H436 wetting agent, 2-amino - 1 part of 2-methyl-1-propanol (AMP-96) additive, 8 parts of WP-5040 dispersant, 2 parts of BZ404 defoamer, 20 parts of ethylene glycol, 14 parts of alcohol ester-12 film-forming aid Parts, 150 parts of rutile titanium powder R-215 coloring agent, 50 parts of heavy calcium carbonate 800 coloring agent, 50 parts of kaolin 1250 coloring agent, 50 parts of mica powder 1250 filler, containing silicon dioxide and aluminum oxide and the fineness is 150 parts of 800-mesh PM2.5 dust nano-beads, 280 parts of YS-8201 styrene-acrylic emulsion, 2 parts of aluminum tripolyphosphate preservative, 40 parts of ATW-2000 aqueous solution, 20 parts of ATW-60 aqueous solution, 2-amino- 1 part of 2-methyl-1-propanol (AMP-95); wherein in the aqueous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com