Conductive polymer material and preparation method thereof

A conductive polymer, conductive carbon black technology, applied in sustainable manufacturing/processing, chemical industry, climate sustainability, etc. Product is light, good mechanical properties, good effect of PTC effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

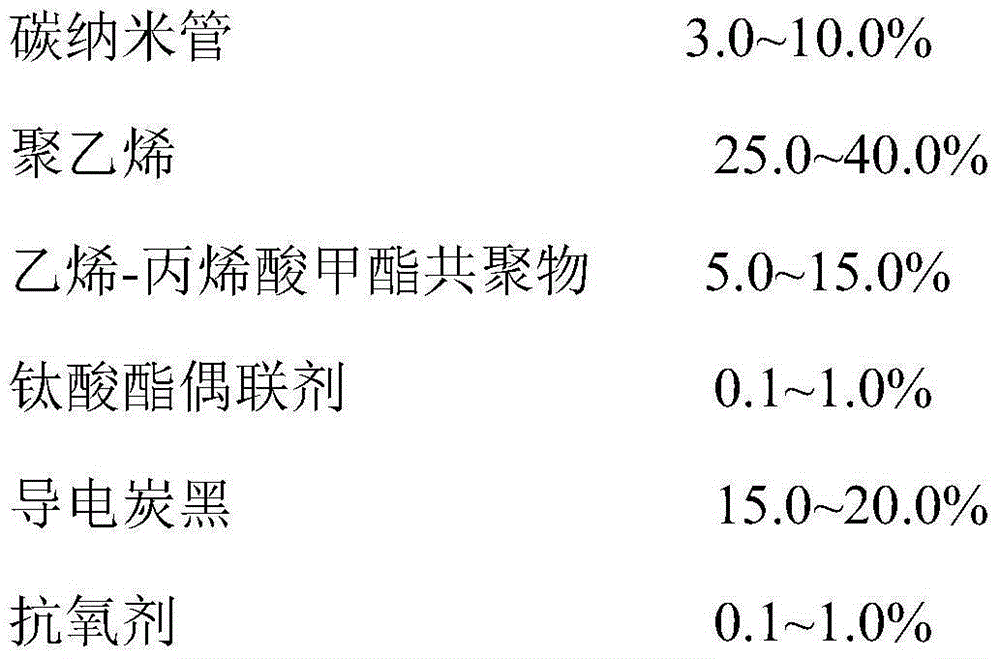

[0019] The conductive polymer material comprises the following components by weight percentage:

[0020]

[0021]

[0022] The conductive polymer material is prepared by tableting method at normal temperature, and the specific steps are as follows: add the ethylene-vinyl acetate, polyethylene, and ethylene-methyl acrylate copolymer in the above-mentioned formula amount into a low-mixer and mix well, and the low-mixer The rotation speed is 30-50rpm / min, stirring for 5-15min; continue to add the above formula amount of carbon nanotubes, conductive carbon black, titanate coupling agent and antioxidant into the low mixer, stir for 5-8min, and The above materials are fully mixed; the mixed materials are extruded and granulated by a twin-screw extruder, the speed of the twin-screw extruder is 80-200rpm / min, and the extrusion temperature is 180-200°C; The pellets are dried at a temperature of 70-80°C for 1-2 hours, and a conductive polymer material is obtained after drying.

...

Embodiment 2

[0025] The conductive polymer material according to Example 1 also includes the following components in weight percent:

[0026] Fragrance 0.1~1.0%

[0027] Under the condition of normal temperature, the conductive polymer material is prepared by tableting method, and the specific steps are as follows: add the ethylene-vinyl acetate, polyethylene, ethylene-methyl acrylate copolymer and aromatic agent in the formula amount into the low mixer and mix evenly. The speed of the mixer is 30-50rpm / min, stirring for 5-15 minutes; continue to add the formula amount of carbon nanotubes, conductive carbon black, titanate coupling agent and antioxidant into the low-speed mixer, and stir for 5-8 minutes. Fully mix the above materials; extrude the mixed materials into pellets through a twin-screw extruder, the speed of the twin-screw extruder is 80-200rpm / min, and the extrusion temperature is 180-200°C; The molded pellets are dried at a temperature of 70-80° C. for 1-2 hours, and a conduct...

Embodiment 3

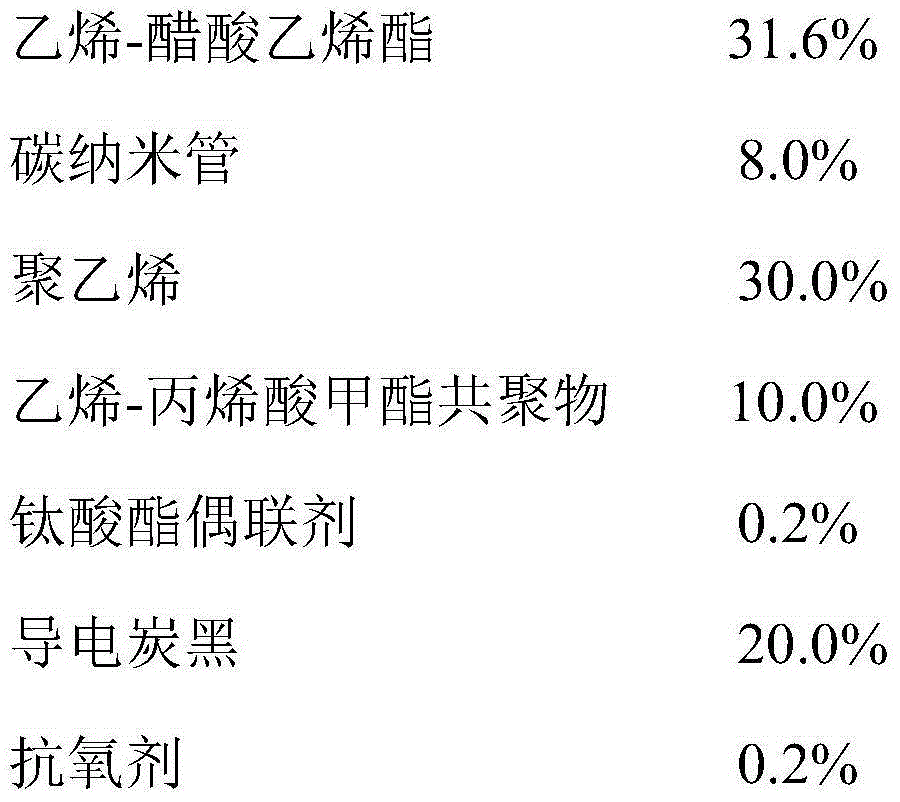

[0030] The conductive polymer material comprises the following components by weight percentage:

[0031]

[0032] When preparing 1000g of conductive polymer material, add 316g of ethylene-vinyl acetate, 300g of polyethylene and 100g of ethylene-methyl acrylate copolymer into the low mixer at a speed of 50rpm / min, and stir for 10min; in the low mixer Continue to add 8g of carbon nanotubes, 200g of conductive carbon black, 2g of titanate coupling agent and 2g of antioxidant, continue to stir for 8 minutes, and fully stir and mix the above materials; extrude the mixed materials through a twin-screw extruder For granulation, the speed of the twin-screw extruder is 100rpm / min, and the extrusion temperature is 200°C; after extrusion, the molded pellets are dried at a temperature of 80°C for 1 to 2 hours, and the conductive polymer is obtained after drying. Material.

[0033] The tensile strength of the conductive polymer material is 12MPa, the elongation at break is 953%, the fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| stretching rate | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com