A branched modifier and corresponding flame retardant nylon resin

A flame retardant nylon and modifier technology, applied in the field of nylon resin, can solve the problems of poor high temperature resistance, affecting the scope of application, easy decomposition, etc., to achieve fast reaction rate, high melt fluidity, and high flame retardant efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

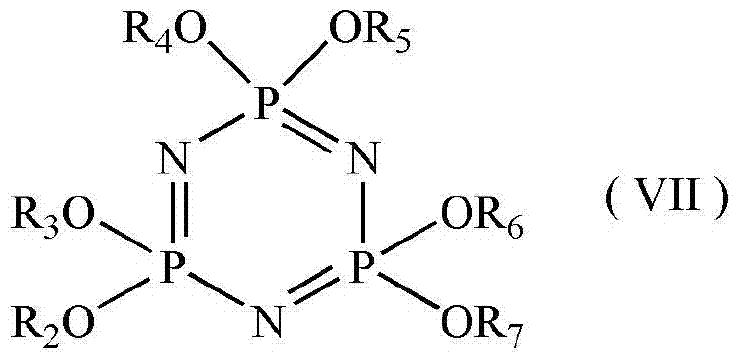

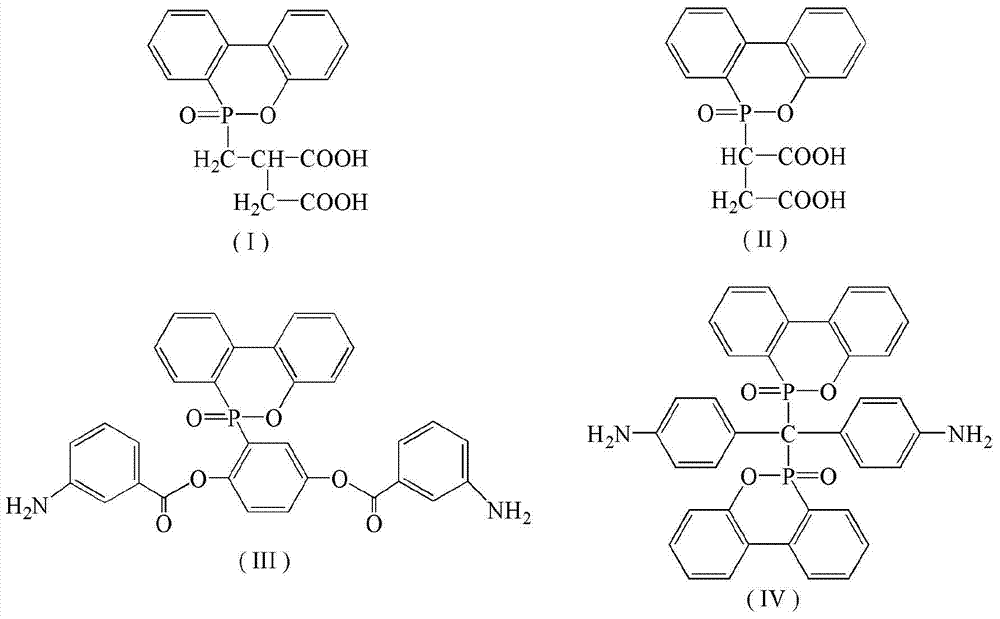

[0039] Preparation method of carboxyl-terminated ring triphosphazene branched modifier

[0040] Taking six (4-carboxyphenoxy) cyclotriphosphazene as an example, its synthesis steps are as follows:

[0041] Equipped with a magnet, thermometer, constant pressure dropping funnel, condensing return tube and N 2In the 1L three-neck flask of the protection device, add 125g of p-hydroxybenzaldehyde, 140g of anhydrous potassium carbonate and 500ml of tetrahydrofuran in sequence, stir at room temperature to dissolve it; weigh 50g of hexachlorocyclotriphosphazene and dissolve it in 100ml of tetrahydrofuran, and slowly Add it dropwise to the above reaction system, and reflux at 65°C for 24h after the dropwise addition. Filtrate, concentrate the filtrate, pour it into deionized water to produce a white precipitate, the precipitate obtained is washed twice with deionized water, recrystallized in ethyl acetate, and vacuum-dried at room temperature for 24h, the intermediate product hexa(4- ...

preparation example 2

[0045] Preparation method of amino-terminated cyclotriphosphazene branched modifier

[0046] Taking six (4-aminophenoxy) cyclotriphosphazene as an example, its synthesis steps are as follows:

[0047] Equipped with a magnet, thermometer, constant pressure dropping funnel, condensing return tube and N 2 In the 500ml there-necked flask of protection device, add 20g hexachlorocyclotriphosphazene, 58g p-nitrophenol, 58g potassium carbonate and 250ml tetrahydrofuran successively; 2 Heated and stirred under protection, and refluxed at 65°C for 24h. The reacted mixture was filtered while it was hot, and the filter residue was washed with ice water, acetone, methanol and diethyl ether in sequence, and finally the solid was put into a vacuum drying oven and dried at room temperature for 24 hours to obtain a white powder as the intermediate product hexa(4-nitrophenoxy ) cyclotriphosphazene with a yield of 84.7%.

[0048] Weigh 10g of hexa(4-nitrophenoxy)cyclotriphosphazene, 60g of st...

Embodiment

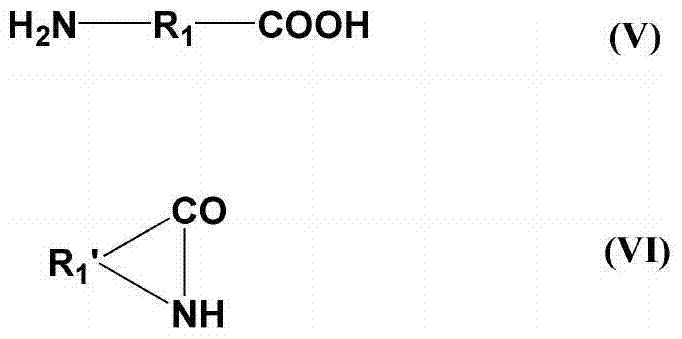

[0051] Embodiment 1-6 and comparative example 1-4 all prepare nylon resin by raw material and consumption shown in table 1, wherein comparative example 1 and 2 do not use reactive flame retardant and branched modifier, comparative example 3 does not use branched Chemical modifier, comparative example 4 did not use reactive flame retardant. The specific preparation method is as follows:

[0052] (1) According to the ratio shown in Table 1, first salt the reactive flame retardant with diamine or dicarboxylic acid in water, and then mix the obtained salt solution with nylon polymer monomer and branched modifier evenly .

[0053] (2) Put the prepared materials into the high-pressure reaction kettle, close the feeding cover tightly, and connect the condensed water; fill the high-purity nitrogen until the pressure in the kettle is 0.2-0.5MPa, and slowly open the exhaust valve to vacuum to make the pressure in the kettle Reduce to -0.03 to -0.05MPa, repeat this operation 3 times, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com