Vegetable and fruit waste integrated treatment process

A treatment process and waste technology, which is applied in the field of integrated treatment process of vegetable and fruit waste, can solve the problems of long time of retting, low fertilizer efficiency, waste, etc., and achieve the effect of shortening composting time, reducing pollution, and high content of nutrient elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

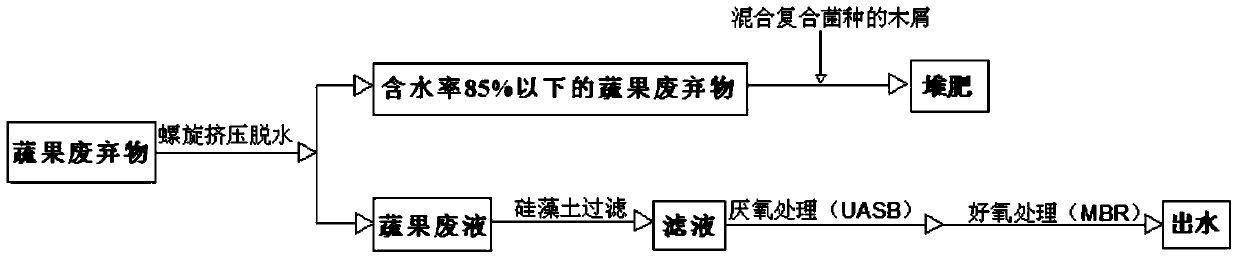

[0016] use figure 1 The process for the integrated treatment of fruit and vegetable waste includes the following steps:

[0017] (1) First, the vegetable and fruit waste is dehydrated by a screw extrusion method, and the moisture content of the dehydrated vegetable and fruit waste is 80%, and the dehydrated vegetable and fruit waste is mixed with Bacillus subtilis and Bacillus microbiota at a mass ratio of 1:0.4. , Bacillus megaterium, Bacillus jelly, and Enterococcus faecalis are evenly mixed, and the moisture content after mixing is 60%, and then stacked into a long strip with a bottom width of 1 meter and a height of 0.5 meters. After the temperature rises to 55 degrees Celsius, Keep it for 2 days, then turn the pile twice a day. After turning the pile continuously for 18 days, you will get a fully fermented organic fertilizer. After testing, the nitrogen content is 550mg / kg, the phosphorus content is 1006mg / kg, the potassium content is 15.9g / kg, and the organic matter con...

Embodiment 2

[0020] An integrated treatment process for fruit and vegetable waste, first dehydrating the fruit and vegetable waste, and dehydrating the fruit and vegetable waste by means of screw extrusion, the dehydrated fruit and vegetable waste has a moisture content of 84%, and the dehydrated fruit and vegetable waste is mixed with Composting and fermenting sawdust mixed with compound strains together, the mass ratio of dehydrated vegetable and fruit waste to sawdust mixed with compound strains was 1:0.5. The mixture of dehydrated fruit and vegetable waste and sawdust mixed with compound strains has a moisture content of 59% and a carbon-to-nitrogen ratio of 30:1. For Bacillus and Enterococcus faecalis, inoculate the culture medium of Bacillus subtilis, Bacillus microbiota, Bacillus megaterium, Bacillus jelly and Enterococcus faecalis on the medium at a volume ratio of 3:2:1:1:1, after After culturing, the mixed bacterial solution is obtained, put the mixed bacterial solution into the ...

Embodiment 3

[0023] An integrated treatment process for fruit and vegetable waste, first dehydrating the fruit and vegetable waste, and dehydrating the fruit and vegetable waste by means of screw extrusion, the dehydrated fruit and vegetable waste has a moisture content of 75%, and the dehydrated fruit and vegetable waste is mixed with Composting and fermenting sawdust mixed with compound strains together, the mass ratio of dehydrated vegetable and fruit waste to wood chips mixed with compound strains was 1:0.3. The moisture content of the mixture of dehydrated vegetable and fruit waste and sawdust mixed with composite strains is 60%. The composite strains include Bacillus subtilis, Bacillus microbiota, Bacillus megaterium, Bacillus jelly and Enterococcus faecalis, The culture solution of Bacillus subtilis, Bacillus microbiota, Bacillus megaterium, Bacillus jellies and Enterococcus faecalis was inoculated on the medium at a volume ratio of 5:4:3:1:1, and a mixed bacterial solution was obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com