High-transparency polyethylene film and preparation method thereof

A polyethylene film, transparent technology, applied in the field of plastic processing, can solve the problems of good transparency and high heat sealability and physical strength, etc., to achieve the effect of improving transparency, maintaining printing effect, and increasing smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

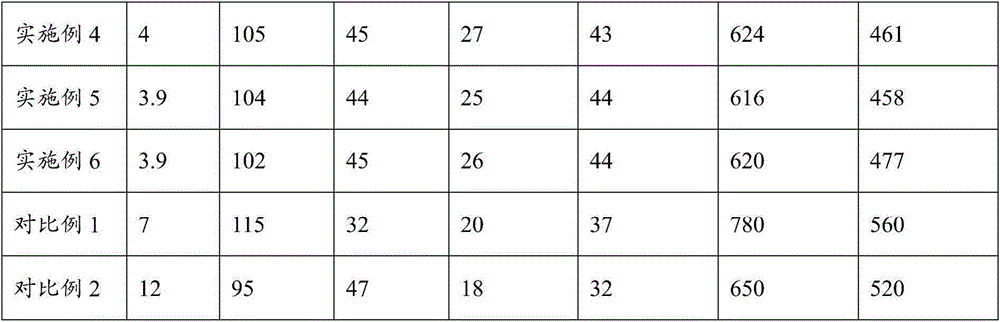

Examples

Embodiment 1

[0024] The high transparent polyethylene film described in this embodiment is composed of three layers of co-extruded film, wherein the outer layer is composed of 35 parts by weight of SP2520 with a melt index of 2g / 10min and 65 parts by weight of 2420H with a melt index of 2g / 10min ; The middle layer is compounded by 70 parts by weight of 920A with a melt index of 1g / 10min and 30 parts by weight of 2426H with a melt index of 2g / 10min; the inner layer is composed of 35 parts by weight of SP2520 and a melt index of 2g / 10min 65 parts by weight of 2426H with a melt index of 2 g / 10 min; the thickness ratio of the outer layer to the middle layer and inner layer is 1:4:1.

[0025] In this embodiment, the raw materials of each layer are added to the extruders of each layer to melt, plasticize and extrude, and the film is blown under the conditions of the inflation ratio of 2.5 and the traction ratio of 6, and then cooled by the cooling air ring. A highly transparent polyethylene film...

Embodiment 2

[0027] The highly transparent polyethylene film described in this example is composed of three layers of co-extruded film, wherein the outer layer is composed of 20 parts by weight of SP2520 with a melt index of 2g / 10min and 80 parts by weight of 2420H with a melt index of 2g / 10min The middle layer is compounded by 80 parts by weight of 920A with a melt index of 1g / 10min and 20 parts by weight of 2426H with a melt index of 2g / 10min; the inner layer is composed of 50 parts by weight of SP2520 and a melt index of 2g / 10min 50 parts by weight of 2426H with a melt index of 2 g / 10 min; the thickness ratio of the outer layer to the middle layer and inner layer is 1:3:1.

[0028] In this embodiment, the raw materials of each layer are added to the extruders of each layer to melt, plasticize and extrude, and the film is blown under the conditions of the inflation ratio of 2 and the traction ratio of 7, and then cooled by the cooling air ring. A highly transparent polyethylene film with...

Embodiment 3

[0030] The highly transparent polyethylene film described in this example is composed of three layers of co-extruded film, wherein the outer layer is composed of 50 parts by weight of SP2520 with a melt index of 2g / 10min and 50 parts by weight of 2420H with a melt index of 2g / 10min The middle layer is compounded by 60 parts by weight of 920A with a melt index of 1g / 10min and 40 parts by weight of 2426H with a melt index of 2g / 10min; the inner layer is composed of 20 parts by weight of SP2520 and a melt index of 2g / 10min 80 parts by weight of 2426H with a melt index of 2 g / 10min; the thickness ratio of the outer layer to the middle layer and inner layer is 1:3.5:1.

[0031] In this embodiment, the raw materials of each layer are added to the extruders of each layer to melt, plasticize and extrude, and the film is blown under the conditions of the inflation ratio of 2.8 and the traction ratio of 5, and then cooled by the cooling air ring. A highly transparent polyethylene film wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com