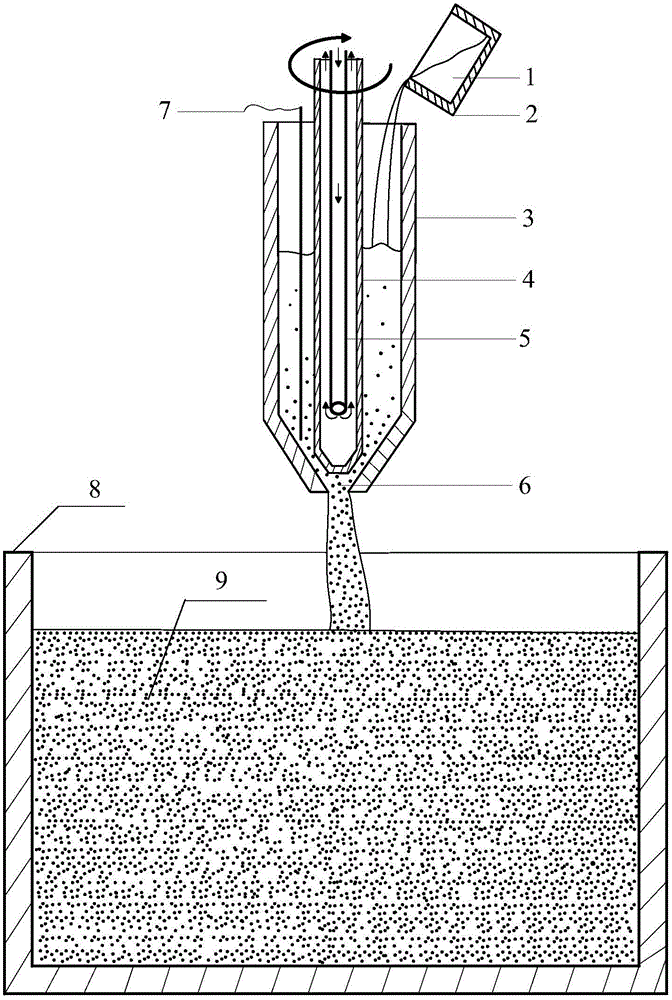

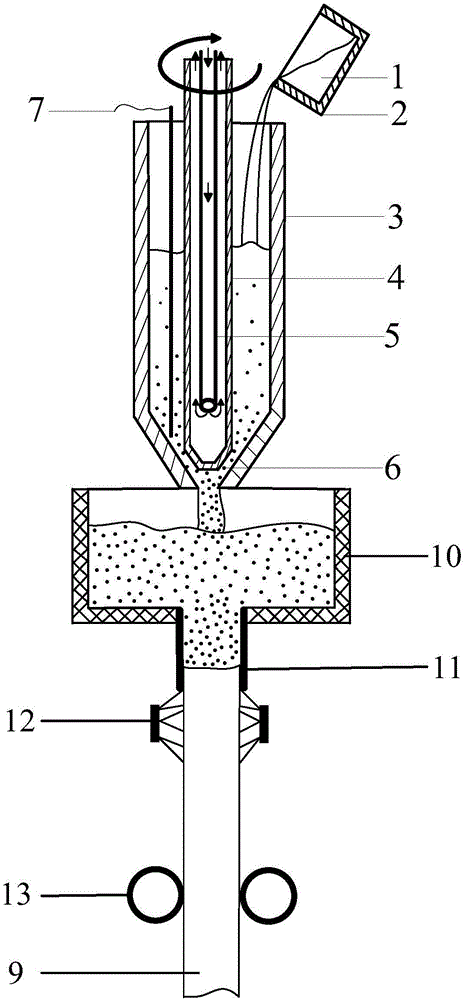

Device and method for preparing large-diameter semi-solid alloy billet

A semi-solid, large-diameter technology, applied in the field of semi-solid alloy processing, can solve problems such as poor reliability of continuous work, small size of billet preparation, and difficulty in industrialization, so as to achieve a wide range of applicable alloys, reduce billet cracking, and improve surface quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Embodiment 1: Preparation of large-diameter semi-solid A380 aluminum alloy billet, the steps are as follows:

[0069] (1-1) The liquidus and solidus temperatures of the die-casting A380 aluminum alloy used in the test are 596°C and 521°C, respectively, and the A380 aluminum alloy ingot is placed in a crucible resistance furnace with a preheating temperature of 300°C. The temperature is raised to 680°C and refined after complete melting. Use a bell jar to press the dried hexachloroethane into the bottom of the melt. The amount added is 0.5% of the total weight of the alloy liquid. Shake gently to remove the alloy melt Gas, slag removal and refining treatment, and finally the alloy melt is cooled to 620°C and then kept warm.

[0070] (1-2) Set the width of the annular gap formed between the inner wall of the pulping chamber and the outer wall of the stirring rod of the semi-solid alloy billet preparation device in this embodiment to be 50 mm, and the angle formed at the c...

Embodiment 2

[0071] Embodiment 2: preparing large-diameter semi-solid 7075 aluminum alloy billet, comprising the following steps:

[0072] (2-1) The liquidus and solidus temperatures of the 7075 aluminum alloy used in the test are 635°C and 477°C, respectively. Put the 7075 aluminum alloy ingot into a crucible resistance furnace with a preheating temperature of 350°C, The temperature is raised to 720°C and refined after complete melting. Press the dried hexachloroethane into the bottom of the melt with a bell jar. The amount added is 0.5% of the total weight of the alloy liquid. Shake gently to remove the alloy melt. Gas, slag removal and refining treatment, and finally the alloy melt is cooled to 660°C and then kept warm.

[0073] (2-2) Set the width of the annular gap formed between the inner wall of the pulping chamber and the outer wall of the stirring rod of the semi-solid alloy billet preparation device in this embodiment to be 70 mm, and the angle formed at the connection between th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com