Large-stroke quick-response X-Y micro-motion workbench with double displacement magnification

A technology of displacement amplification and quick response, which is applied to the parts of the instrument, instruments, etc., can solve the problems of system motion accuracy decrease, motion platform displacement inconsistency, and affect positioning accuracy, so as to improve the load carrying capacity, improve the quick response, Eliminate the effect of displacement coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

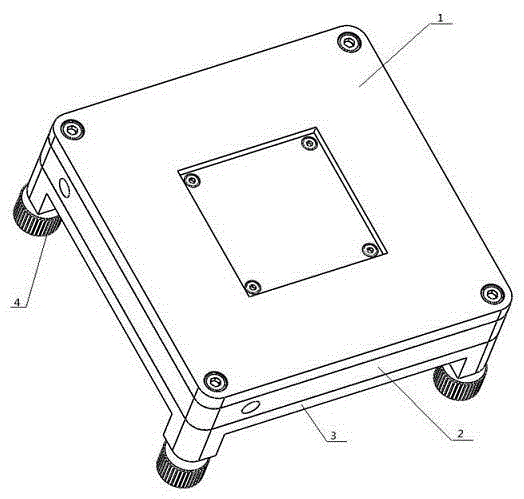

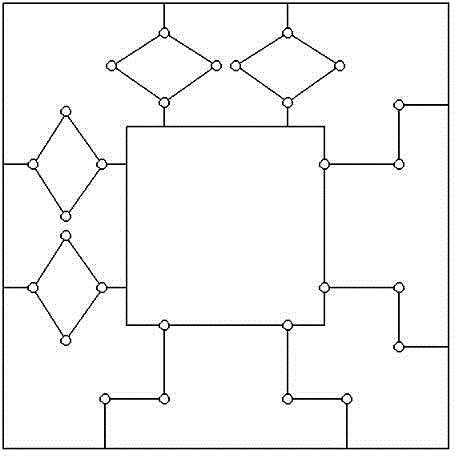

[0036] Such as figure 1 , as shown in 2 and 4, a large-stroke X-Y micro-motion worktable with a double displacement amplification mechanism provided by the present invention is characterized in that it mainly includes a base 3, a motion platform 2, a top cover 1, leveling screws 4, Piezoelectric ceramics (11, 12, 13, 14), stage 7, capacitive displacement sensors (5, 6, 8, 9) and locking screws 10. Wherein the leveling screw 4 is installed on the four corners of the base 3, the base 3 is the motion platform 2, the motion platform 2 is the top cover 1, the base 3, the motion platform 2 and the top cover 1 are fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com