Al-TiO2-C grain refiner, preparation method thereof and commercial-purity aluminum refining method

A grain refiner, al-tio2-c technology, applied in Al-TiO2-C grain refiner and its preparation, in the field of industrial pure aluminum refinement, can solve the problem of insignificant refinement effect and fine TiC particles It is not easy to control, poor anti-recession performance, etc., to achieve good grain refinement effect, excellent grain refinement effect, and moderate quantity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 Al-TiO 2 -The preparation method of C grain refiner

[0041] 1. Material preparation

[0042] In this embodiment, Al powder (purity is 99.9%, particle size is 40-50 μ m), TiO 2 Powder C (purity 99.9%, particle size 30nm) and C powder (purity 99.9%, particle size 30-95 μm) are raw materials.

[0043] 2. Preparation method

[0044] This embodiment prepared 6 different C:TiO 2 Ratio [All C:TiO appearing in the abstract of the specification, abstract drawings, claims, specification and drawings of the specification of the present invention 2 Both refer to the amount of substance of C and TiO 2 The ratio of the amount of substance, no longer repeat them one by one] Al-TiO 2 -C grain refiner. C:TiO 2 The molar ratios are 0, 1:30, 1:25, 1:20, 1:15, 1:10 in turn. Al powder, TiO 2 Powder [TiO in this embodiment 2 The amount of powder added is Al powder, TiO 2 10wt% of the total mass of C powder and C powder], C powder mixed, ball milled on a star ball mill ...

Embodiment 2

[0050] Embodiment 2 Refining method of industrial pure aluminum

[0051] 1. Raw materials and refinement methods of industrial pure aluminum

[0052] Al-TiO prepared with embodiment 1 2 -C grain refiner and industrial pure aluminum are used as raw materials for refinement test; the refinement test is carried out in a crucible resistance furnace, in which Al-TiO 2 The mass of the -C grain refiner is 0.2wt% (mass fraction, the same below) of the mass of industrial pure aluminum. Use a graphite crucible to melt industrial pure aluminum in a crucible resistance furnace. After the temperature rises to 750°C and keep it warm for 30 minutes, add the grain refiner preheated to 250°C into the graphite crucible and stir to make the grain refiner Evenly distributed in pure aluminum. After 30 minutes of heat preservation, it is poured into the KBI standard mold preheated at 200°C, and the pouring temperature is 700°C.

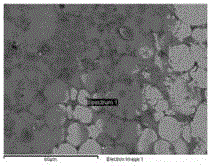

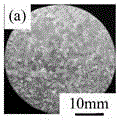

[0053] 2. Different C:TiO 2 Thinning effect than refiner

[005...

Embodiment 3

[0061] In this example Al-TiO 2 The difference between the preparation method of -C grain refiner and embodiment 1 is:

[0062] (1) The amount of C and TiO 2 The ratio of the amount of substance (C:TiO 2 ) is fixed at 1:20;

[0063] (2) Add the following ball milling solvent during ball milling: 1,4-butanediamine, or ethanol, or acetone, or a mixed solvent with a volume ratio of 1,4-butanediamine and ethanol of 2:1, or a volume ratio of ethanol and acetone It is a mixed solvent of 1:3, or a mixed solvent of 1,4-butanediamine, ethanol and acetone with a volume ratio of 2:1:3; after ball milling, dry until the ball milling solvent evaporates completely.

[0064] The Al-TiO that this embodiment makes 2 -C grain refiner is used for industrial pure aluminum refinement, other test conditions are the same as in Example 2, and the test results are shown in Table 1 below:

[0065] Table 1

[0066]

[0067]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com