A kind of expanded graphite and zinc oxide composite modified polyurethane sponge and preparation method thereof

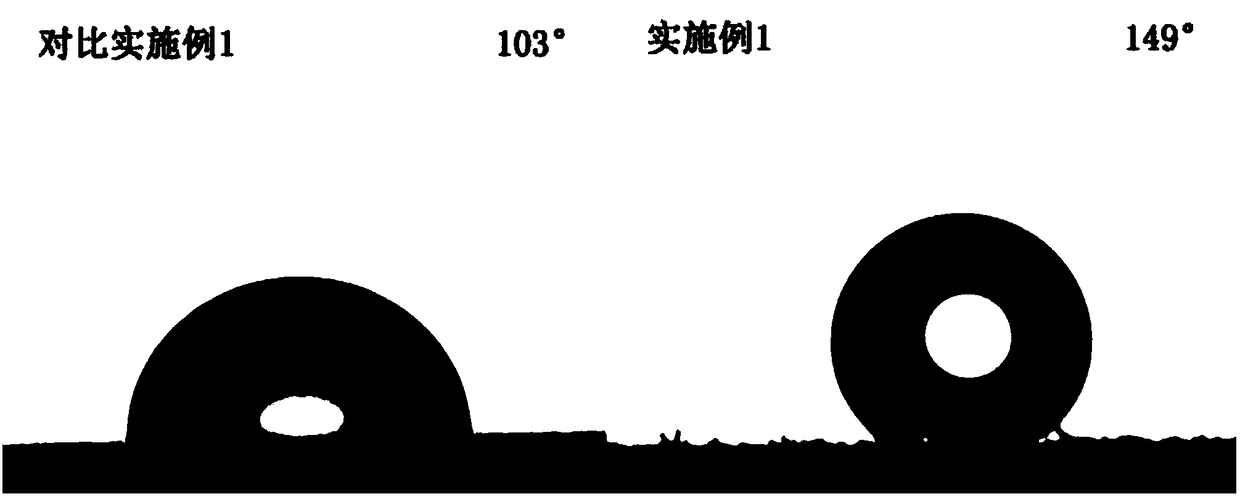

A technology of polyurethane sponge and expanded graphite, applied in the field of polyurethane sponge and its preparation, can solve the problems of weakening the adsorption of oil pollution, restricting development, etc., and achieve the effects of strong oil absorption, environmental protection adsorption material, and strong hydrophobicity and lipophilicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Preparation of expanded graphite dispersion. The expanded graphite prepared in the laboratory with an expansion rate of 310-350mL / g was acid-modified in concentrated sulfuric acid / concentrated nitric acid with a volume ratio of 7:3 for 24 hours, filtered, rinsed with deionized water until neutral, and dried; Put the modified expanded graphite into a mixture consisting of 200ml N,N-dimethylformamide and 6ml tetrabutylammonium hydroxide for 48 hours, filter and wash with ethanol, then ultrasonically disperse in 400ml ethanol solution for 2-3 hours, and filter to obtain expanded graphite The dispersion is ready for use.

[0027] 2) Preparation of zinc oxide colloidal solution. Prepare 200 ml of 0.15 mol / L zinc acetate alcohol solution at 65°C, add ammonia water under stirring conditions until the solution is clear, and continue stirring for 3 hours to obtain a zinc oxide colloidal solution.

[0028] 3) Preparation of polyurethane sponge modified with expanded graphite...

Embodiment 2

[0032] Different oils (diesel oil, lubricating oil, gasoline, soybean oil) and water were separately tested for adsorption by the expanded graphite and zinc oxide composite modified polyurethane sponge prepared by the present invention, in order to obtain the maximum oil / water absorption rate. The test results are shown in Table 1. The oil absorption rate of lubricating oil is as high as 32.86g / g, and the oil absorption rate of gasoline with lower density is 27.79g / g, while the water absorption rate is only 1.24g / g, which shows that the modified Polyurethane sponge has strong hydrophobicity and lipophilicity.

[0033] Table 1 The oil-absorbing and hydrophobic effect of polyurethane sponge modified with expanded graphite and zinc oxide

[0034]

[0035] The expanded graphite and zinc oxide composite modified polyurethane sponge prepared by the invention can be recycled, and after oil absorption, it can be squeezed out to continue oil absorption. Taking diesel oil in water a...

Embodiment 3

[0039] The polyurethane sponge modified by the expansion graphite and zinc oxide compound modified by the present invention is a curve of oil / water absorption rate changing with time. Cut six pieces of modified sponge with a mass of 0.1±0.005g to absorb diesel oil in water, take one of them every once in a while to measure the quality of the modified sponge after adsorption, convert it into adsorption rate, and obtain the curve of oil absorption rate of modified sponge with time ; In the same way, measure the curve of the water absorption of pure water as a function of time of the modified sponge, and the results are as follows: Figure 4 shown. This figure shows that the polyurethane sponge modified with expanded graphite and zinc oxide can reach the saturated adsorption of diesel oil within 2 minutes, and has a very high adsorption rate, while the adsorption rate of water is almost negligible compared with diesel oil. Therefore, The invention can quickly and efficiently selec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com