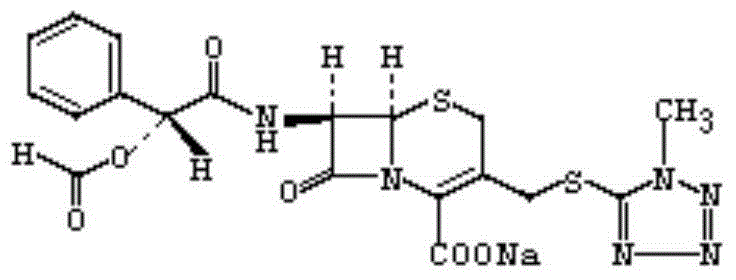

Cefamandole nafate compound entity used for children and preparation thereof

A technology of cefamandole sodium and compound, which is applied in the field of cefamandole sodium compound entity and its preparation for children, can solve the problems of low purification efficiency and increase the difficulty of separation, and achieves improved extraction efficiency, less impurities, The effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) take by weighing 100g of cefamandole sodium crude product, add 1000ml of water to dissolve, add sodium bicarbonate solution to adjust pH to 6.5-7.5, add 10g activated carbon, stir and decolorize, filter;

[0025] (2) Add 10ml of ethyl acetate to the above-mentioned filtrate under stirring, transfer to a 1000ml pressure-resistant container, ensure that it is full and remove air bubbles, seal the container, shake, and take out after freezing at -18°C for 8 hours;

[0026] (3) Liquid-solid separation, after the ice melts, transfer to a crystallizing tank, add 5000ml of ethanol dropwise for about 30 minutes, stir at a slow speed for 30 minutes, continue to grow crystals for 1 hour, suction filtration, wash with ethanol, vacuum dry, and aseptically separate The finished product of cefamandole sodium is obtained. Maximum single miscellaneous 0.23%, total miscellaneous 0.52%.

Embodiment 2

[0028] (1) take by weighing 100g of cefamandole sodium crude product, add 1000ml of water to dissolve, add sodium bicarbonate solution to adjust pH to 6.5-7.5, add 10g activated carbon, stir and decolorize, filter;

[0029] (2) Add 7ml of chloroform to the above-mentioned filtrate under stirring, transfer to a 1000ml pressure-resistant container, ensure that it is full and remove air bubbles, seal the container, shake, and take out after freezing at -18°C for 8 hours;

[0030] (3) Liquid-solid separation, after the ice melts, transfer to a crystallizing tank, add 5000ml of ethanol dropwise for about 30 minutes, stir at a slow speed for 30 minutes, continue to grow crystals for 1 hour, suction filtration, wash with ethanol, vacuum dry, and aseptically separate The finished product of cefamandole sodium is obtained. Maximum single miscellaneous 0.39%, total miscellaneous 0.59%.

Embodiment 3

[0032] (1) take by weighing 100g of cefamandole sodium crude product, add 1000ml of water to dissolve, add sodium bicarbonate solution to adjust pH to 6.5-7.5, add 10g activated carbon, stir and decolorize, filter;

[0033] (2) Add 10ml of ether to the above-mentioned filtrate under stirring, transfer it to a 1000ml pressure-resistant container, ensure that it is full and remove air bubbles, seal the container, shake, and take out after refrigerating at -18°C under temperature control for 3 hours;

[0034] (3) Remove the organic phase, after the ice melts, transfer to a crystallizing tank, add 5000 ml of ethanol dropwise for about 30 minutes, stir at a slow speed for 30 minutes, continue to grow crystals for 1 hour, filter with suction, wash with ethanol, vacuum dry, and aseptically separate The finished product of cefamandole sodium is obtained. The largest single miscellaneous 0.27%, the total miscellaneous 0.54%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com