Large block porous zeolite composed of nano-crystal grains and preparation method thereof

A porous zeolite, nanocrystalline technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., to achieve good thermal and hydrothermal stability, diffusion rate and acid site accessibility improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] At room temperature, dissolve 5.31g of sodium chloride, 5.30g of tetrapropylammonium bromide (TPABr), and 1.13g of sodium aluminate in 60mL of distilled water to form a clear and transparent solution, then add 1.70g of 98% concentrated sulfuric acid dropwise, and stir well , slowly add 76.00g of 40% silica sol, then add 4.08g of sodium hydroxide, and continue to stir evenly.

[0030] Heat the above gel and keep the temperature at 80°C, add 2.00g of sodium carboxymethylcellulose, continue to stir for 180min, and dry until there is no obvious weight loss to make a block dry gel.

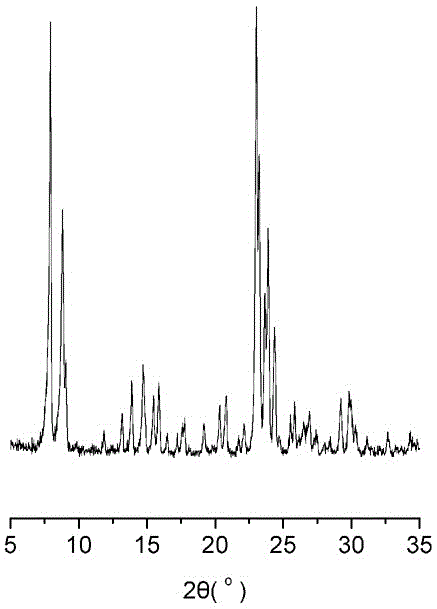

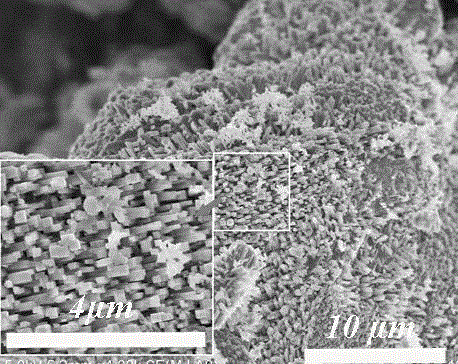

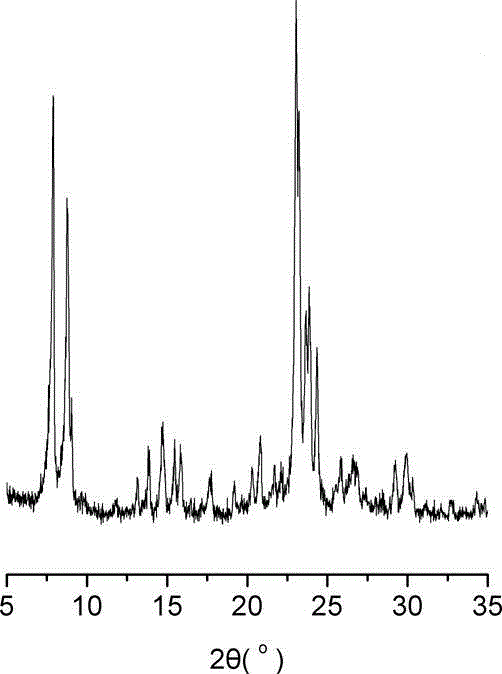

[0031] Place a bracket at the bottom of the stainless steel reaction kettle, place a container with a hole in the bottom on the upper layer of the bracket, weigh 5.00g of the above block dry glue, wrap it with filter paper and put it on the container with holes. Inject 3.00g of ethylenediamine, a gas template in the vapor phase inversion process, into the bottom of the reactor, seal it, and crys...

Embodiment 2

[0033] At room temperature, dissolve 10.00g of sodium chloride, 5.30g of tetrapropylammonium bromide (TPABr), and 1.13g of sodium aluminate in 40mL of distilled water to form a clear and transparent solution, then add 1.25g of 98% concentrated sulfuric acid dropwise, and stir well , slowly add 89.00g of 40% silica sol, then add 8.00g of sodium hydroxide, and continue to stir evenly.

[0034] Heat the above gel and keep the temperature at 75°C, add 1.50g of sodium hydroxyethyl cellulose, continue to stir for 120min, and dry until there is no obvious weight loss to make a block dry gel.

[0035]Place a bracket at the bottom of the stainless steel reaction kettle, place a container with a hole in the bottom on the upper layer of the bracket, weigh 6.00g of the above-mentioned block dry glue, wrap it with filter paper and put it on the container with holes. Inject 5.00 g of the mixed solution of ethylenediamine and diethylamine, the gas template in the vapor phase inversion proces...

Embodiment 3

[0038] At room temperature, dissolve 6.50g of sodium chloride, 6.89g of tetrapropylammonium bromide (TPABr), and 1.13g of sodium aluminate in 40mL of distilled water to form a clear and transparent solution, then add 1.00g of 98% concentrated sulfuric acid dropwise, and stir well , slowly add 25.00g of 40% silica sol, then add 1.00g of sodium hydroxide, and continue to stir evenly.

[0039] Heat the above gel and keep the temperature at 60°C, add 0.50 g of sodium carboxymethylcellulose, continue to stir for 30 min, and dry until there is no obvious weight loss to make a block dry gel.

[0040] Place a bracket at the bottom of the stainless steel reaction kettle, place a container with a hole in the bottom on the upper layer of the bracket, weigh 2.00g of the above-mentioned block dry glue, wrap it with filter paper and put it on the container with holes. Inject 2.00 g of the mixed solution of diethylamine and triethylamine as the gas template in the vapor phase inversion proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com