A diameter reducing device for automatic oiling operation

A technology of reducing diameter and applying oil, which can be applied to devices and coatings that apply liquid to the surface. It can solve the problems of rusting of metal and rubber components, uneven coating of anti-rust oil, and difficulty in ensuring the quality of work. , to achieve the effect of shortening production cycle, easy control of operation quality and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The content of the present invention will be described below in conjunction with specific embodiments.

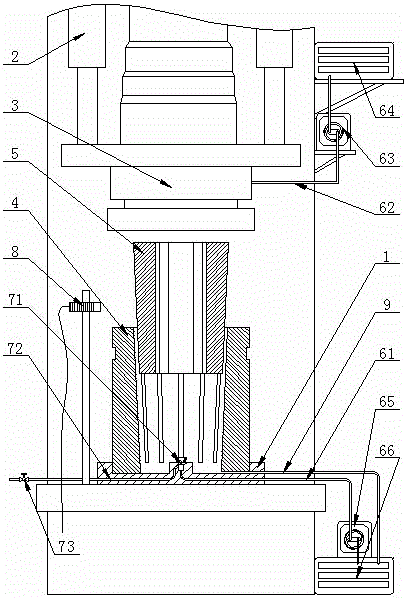

[0025] Such as Figure 1 to Figure 3 As shown, it is a structural schematic diagram of a diameter reducing device for automatic oiling operation according to the present invention. A diameter reducing device for automatic oiling operation according to the present invention, comprising: a diameter reducing mechanism and an oiling mechanism;

[0026] The diameter reduction mechanism includes a diameter reduction base 1 and a diameter reduction cylinder 2 fixedly arranged relative to the diameter reduction base 1. The telescopic working end of the bottom of the diameter reduction cylinder 2 is provided with a diameter reduction pressure head 3; The upper end of the diameter base 1 is provided with a reduced-diameter Huff, and the reduced-diameter Huff is located below the reduced-diameter indenter 3 and includes a cylindrical Huff sleeve 4, a circle arranged in the Huf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com