A two-color optical fiber coloring mold

A two-color optical fiber and mold technology, applied in the direction of bundled optical fibers, marked conductors/cables, coatings, etc., can solve the problems of slow production speed and reduced production efficiency, and achieve the goal of improving production efficiency, increasing production speed, and reducing production processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

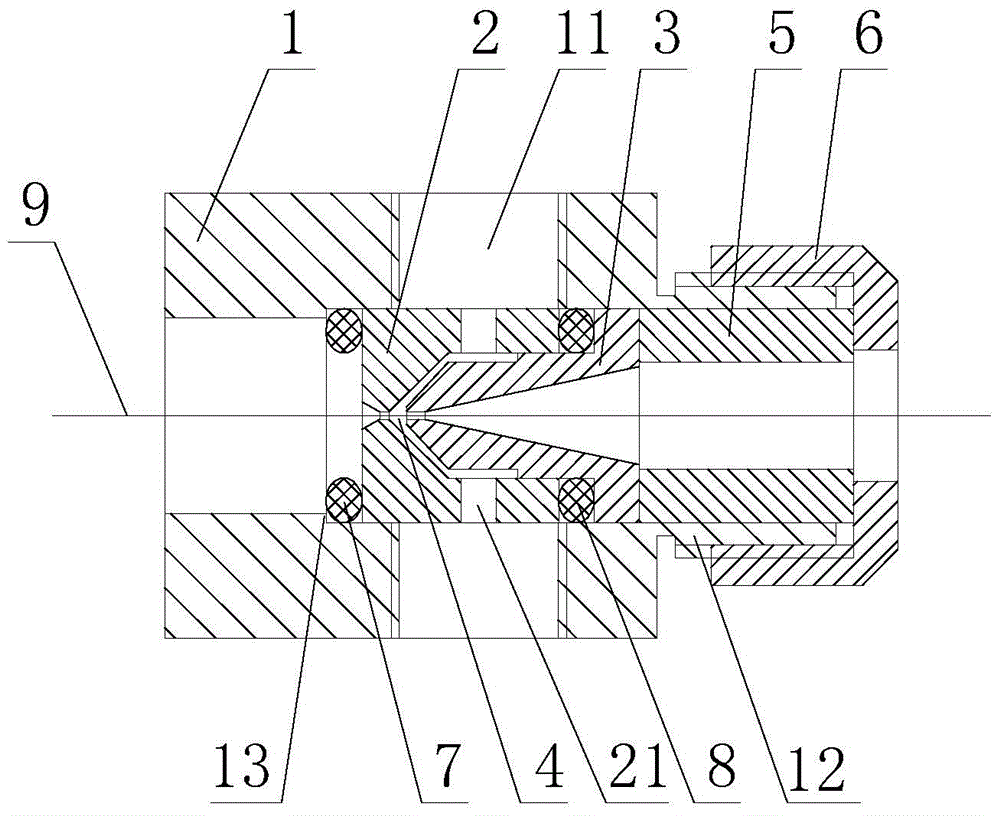

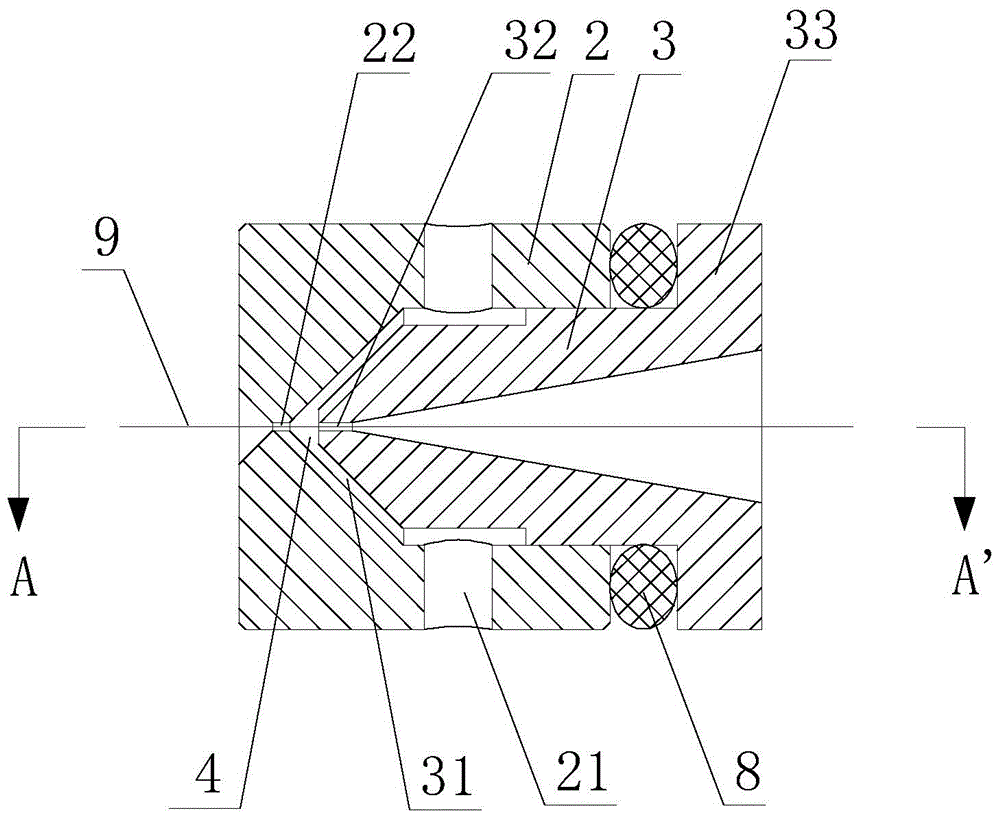

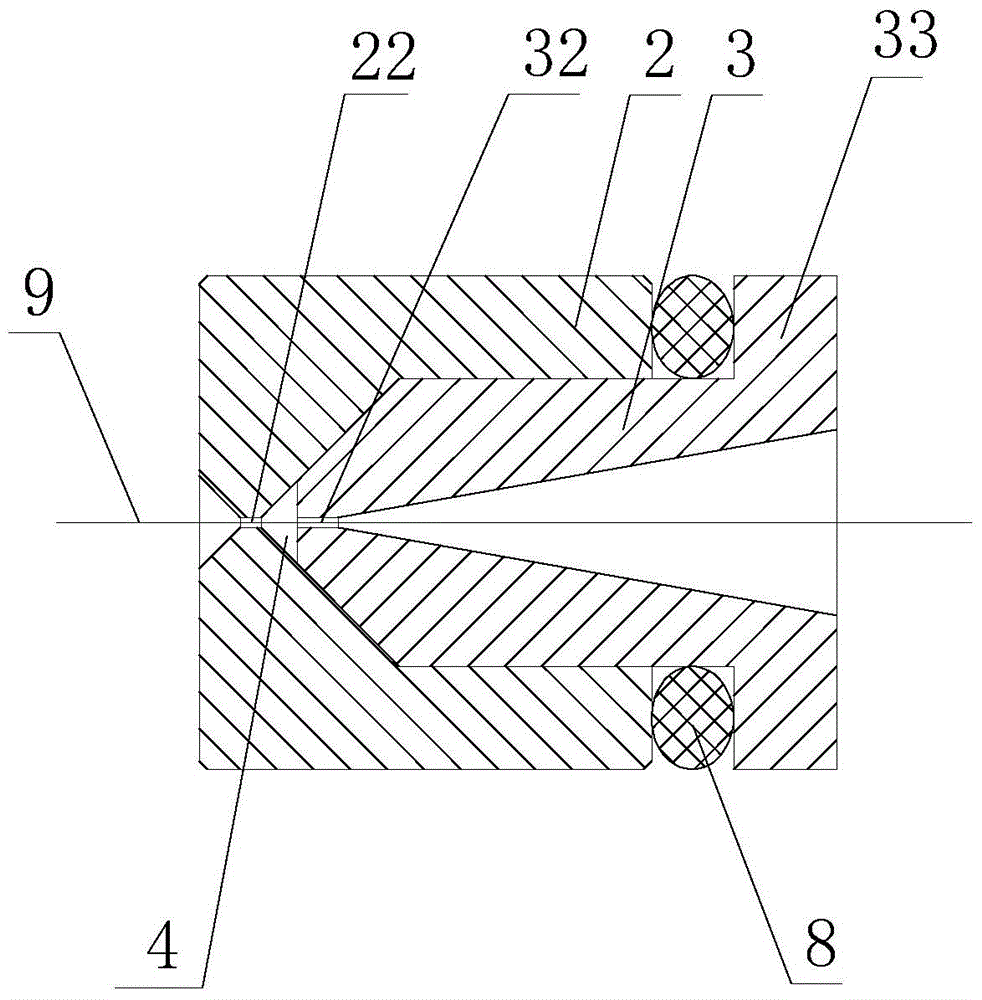

[0030] The two inks are injected into the two injection ports 11 of the ink cup 1 through the same pressure system. The ink is isolated through the first tapered mating surface and the second tapered mating surface between the inlet die 3 and the outlet die 2, and the two separated inks pass through the feed channel 31 in the ink chamber 4 under the same pressure. Start mixing, because the optical fiber 9 travels faster at this time, the ink flowing here is quickly taken out of the outlet die 2 by the optical fiber 9 before it can be mixed, and after passing through the UV curing furnace, the inks of the two colors are cured on the optical fiber. On, a two-color fiber is formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com