A universal joint outer ball cage and its processing technology

A processing technology and outer ball cage technology, which is applied in the field of automotive parts fixtures, can solve problems that affect the service life and use effect, the material has no self-lubricating performance, and the process route becomes longer, so as to shorten the processing route and improve wear resistance and performance. Self-lubricating performance, the effect of reducing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

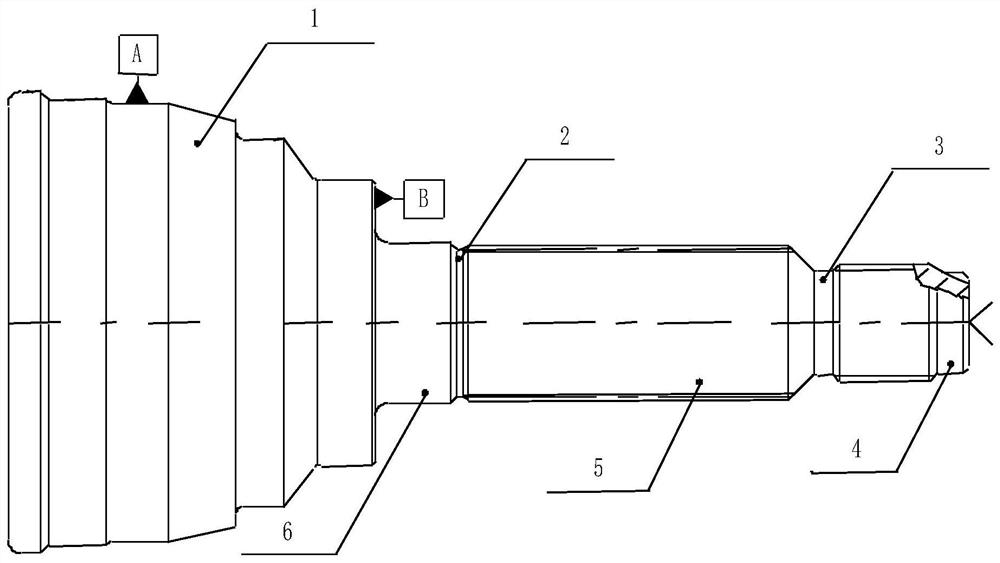

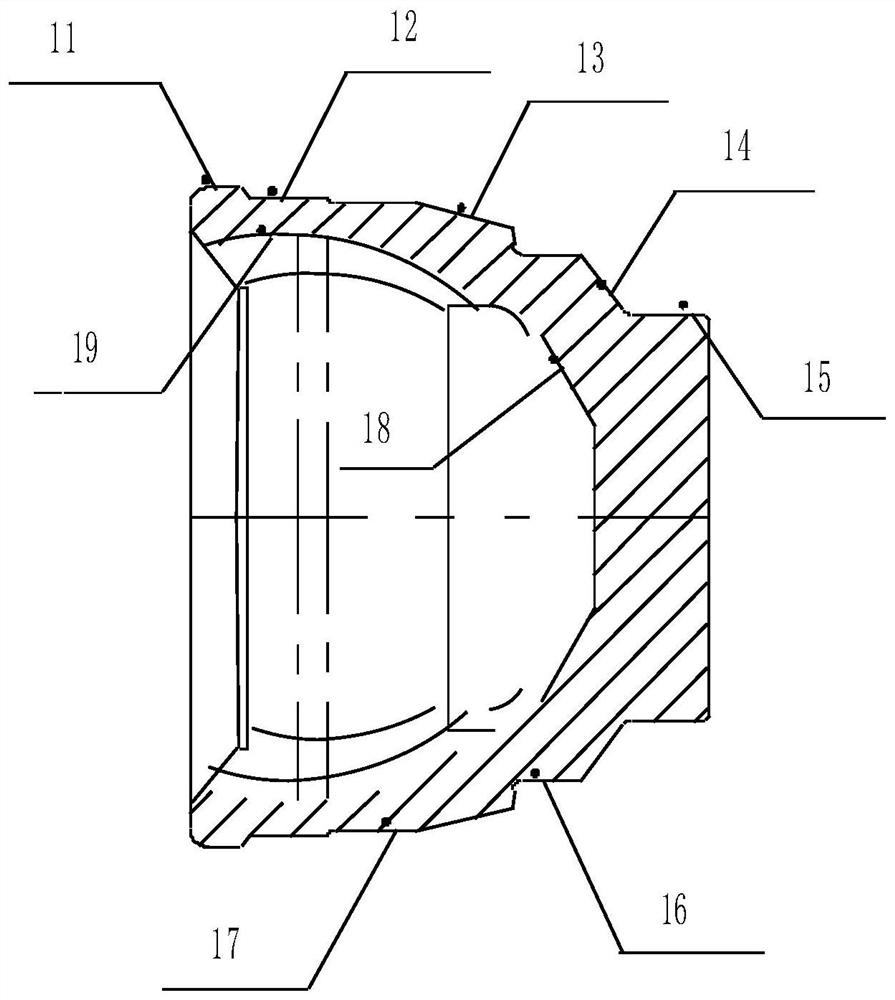

[0036] figure 1 and figure 2 Shows a specific embodiment of the present invention, a universal joint outer cage, including a bell section 1, a first transition section 2, a second transition section 3, an external thread section 4, a spline section 5 and a cylindrical section 6 , the right end face of the bell section 1 is provided with a cylindrical section 6 and the junction of the bell section 1 and the cylindrical section 6 adopts a circular arc transition, the right end surface of the cylindrical section 6 is provided with a first transition section 2 and the cylindrical section 6 The junction with the first transition section 2 is provided with a chamfer, the right end surface of the first transition section 2 is provided with a spline section 5 and the right end surface of the spline section 5 is provided with a chamfer, and the right end surface of the spline section 5 is A second transition section 3 is provided at the right end surface of the second transition sect...

Embodiment 2

[0045] A processing technology for an outer ball cage of a universal joint, comprising the following steps:

[0046] Step 1: Carry out bar blanking according to the external dimensions of the universal joint outer ball cage. The bar is made of Fe: 54% to 68%, Cr: 12% to 15%, Ni: 11% to 12%, and the balance impurities, prefabricated mixed matrix;

[0047] Step 2: The bar is drawn and hot forged by a forging die to produce a universal joint outer ball cage blank, while drawing and hot forging, adding C: 11.2% to 13.5%, Si: 1.4% to 1.8%, Mn: 0.1% to 0.5%, S: ≤0.015% powder; drawing and hot forging temperatures are controlled at 810°C to 830°C, and air-cooled to room temperature at the same time, so that the hardness reaches HRC55 and the tensile strength reaches 780MPa.

[0048] Step 3: Clamp the left end of the blank through the chuck, use a CNC lathe to rough the outer diameter and drill a hole at the center of the right end face of the external thread section 4;

[0049] Ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com