High-durability thin-type IPS polaroid and manufacturing method thereof

A durable and polarizer technology, applied in the direction of optics, optical components, polarizing components, etc., can solve the problems of increasing product thickness, high moisture permeability, easy film breakage or wrinkling, etc., to reduce production processes, save time, and prevent volatilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

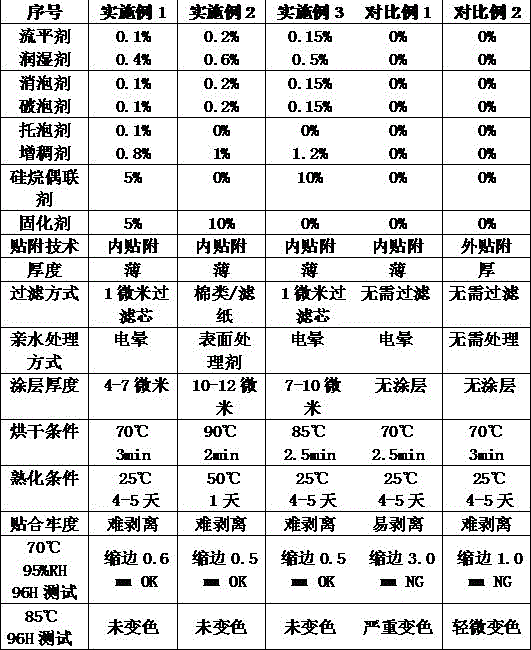

Embodiment 1

[0029] The first step is to prepare a hydrophilic coating solution. The polyurethane is diluted with water to obtain the hydrophilic coating mother liquor; the auxiliary agent is added to the hydrophilic coating mother liquor to obtain the hydrophilic coating solution. The auxiliary agent includes 0.1% of the mass fraction of the hydrophilic coating solution, a leveling agent, 0.4% of a wetting agent, and 0.8% of a thickening agent.

[0030] Because the bubbles in the hydrophilic coating solution can cause point defects in the coating on the polarizer, such point defects are even visible to the naked eye. Therefore, the defoaming agent, the foaming agent and the foam breaking agent which account for 0.1% of the mass fraction of the hydrophilic coating solution are respectively added.

[0031] In order to increase the adhesion of the hydrophilic coating solution, 5% of the mass fraction of the hydrophilic coating solution is added with a silane coupling agent and 5% of a curing age...

Embodiment 2

[0040] The first step is to prepare a hydrophilic coating solution. The steps are the same as in Example 1, but the added additives include a leveling agent, 0.6% wetting agent, 1% thickener, 0.2% defoamer, and 0.2% of the mass fraction of the hydrophilic coating solution. 0.2% foam breaker, 10% curing agent. Do not add any foaming agent and silane coupling agent.

[0041] After adding all the additives, stir well, and then filter the hydrophilic coating solution with 2-3 layers of cotton or filter paper.

[0042] In the second step, a surface treatment agent is applied to the surface of the PC film, and the surface treatment agent is a corona-free surface treatment agent or a PET film attachment accelerator. After the treatment agent is applied, a hydrophilic coating solution is applied to the upper layer. The thickness of the dry glue is controlled at 10-12 microns by the method of scraping.

[0043] The third step is the same as the third step in Example 1.

[0044] The fourth ...

Embodiment 3

[0049] The first step is to prepare a hydrophilic coating solution. The steps are the same as in Example 1, but the added additives are 0.15% of the mass fraction of the hydrophilic coating solution, a leveling agent, 0.5% wetting agent, 1.2% thickener, 0.15% defoamer, 0.15% foam breaker, 10% silane coupling agent. Do not add any foaming agent and curing agent.

[0050] After adding all the additives, stir well, and then filter the hydrophilic coating solution with a 1 micron filter.

[0051] The second step is the same as the second step of Example 1, but the coating thickness is controlled at 7-10 microns.

[0052] The third step is the same as the third step in Example 1.

[0053] The fourth step is the same as the fourth step of Example 1, but the drying temperature of the PVA glue is 85°C for 2.5 minutes.

[0054] The fifth step is the same as the fifth step in Example 1.

[0055] The sixth step is the same as the sixth step in Example 1.

[0056] The seventh step is the same as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com