Copper strip surface treatment method and device

A technology for surface treatment and copper tape, applied in the field of non-ferrous metal processing, can solve problems such as copper tape sticking, and achieve the effect of preventing adhesion, no color difference, and high surface quality of copper tape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

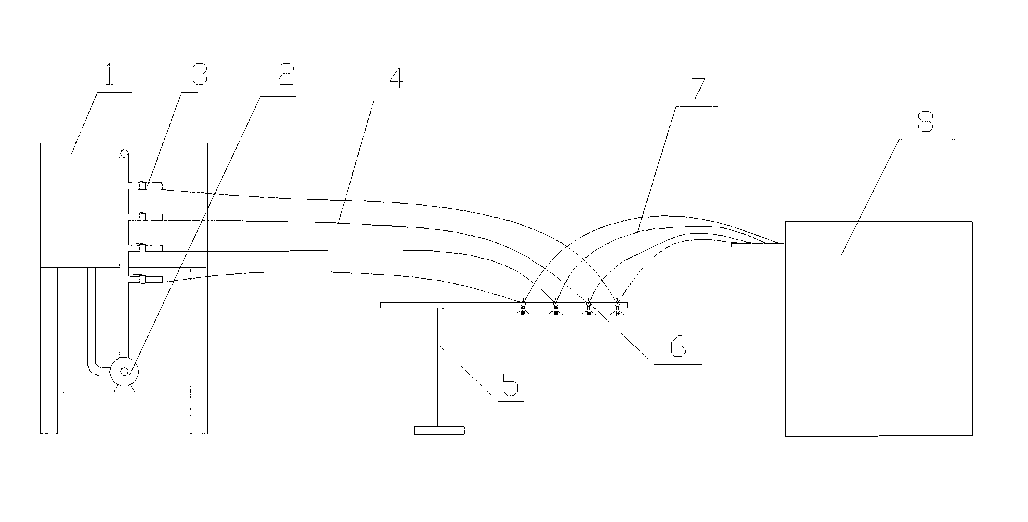

[0015] The implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0016] A copper strip surface treatment method in this embodiment includes rolling, spraying anti-sticking agent, and annealing process, and firstly carries out the rolling process: the rolling process adopts a reversible hydraulic AGC cold rolling mill to roll the copper strip, and the copper strip The thickness of the incoming material is 1.5mm-0.1mm, the front tension is controlled at 1.0-8.0KN, the rear tension is controlled at 2.5-10.0KN, the rolling speed is 250-360m / min, and the processing rate of the rolling pass: 20-40% , the thickness of the copper strip after rolling is 1.2 mm to 0.06 mm.

[0017] Then carry out the spray anti-sticking agent process: adopt the described copper strip surface treatment device, such as figure 1 As shown, it includes an anti-sticking agent solution tank 1, a water pump 2, a ball valve 3, a hose 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com