Pipettor close performance detection device

A technology for inspection devices and pipettes, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and detecting the appearance of fluid at the leak point, etc., which can solve the problems of accuracy of pipetting results, unqualified tightness, etc. problems, to achieve the effect of improving product qualification rate and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

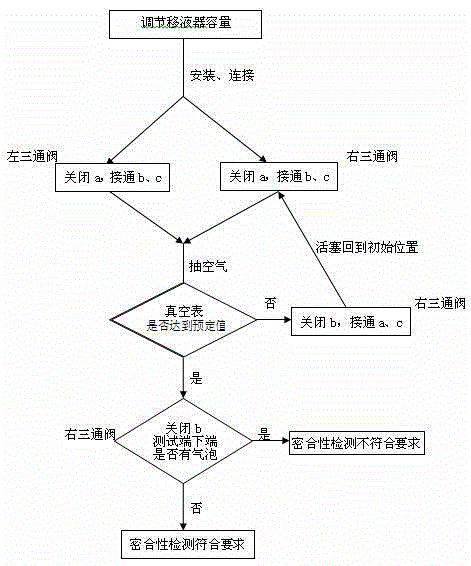

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] Such as figure 1 , figure 2 As shown, a pipette sealing test device, the device consists of a transparent reagent bottle 1, glass syringe 2, right latex tube 3, right three-way valve 4, right glass tube 5, vacuum pressure gauge 6, left glass tube 7. The left three-way valve 8, the left latex tube 9, the liquid suction nozzle 10, and the soft rubber stopper 12 are composed. Soft rubber stopper 12 and the bottleneck of transparent reagent bottle 1 are for tight fit, and it is fixed on the bottleneck of transparent reagent bottle 1. The vacuum pressure gauge 6 is fixed on the central part of the soft rubber bottle stopper 12, and is used for measuring the degree of vacuum in the transparent reagent bottle 1. The right glass tube 5 and the left glass tube 7 are relatively arranged at the two ends of the vacuum pressure gauge 6 . One end of the right glass t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com