Ultralow-temperature coal economizer for single-reheat unit

A reheating unit, ultra-low temperature technology, applied in feed water heaters, preheating, reducing greenhouse gases, etc., can solve problems such as lifting the heat consumption of the unit and increasing exergy losses, and achieve the effect of reducing losses and reducing coal consumption for power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

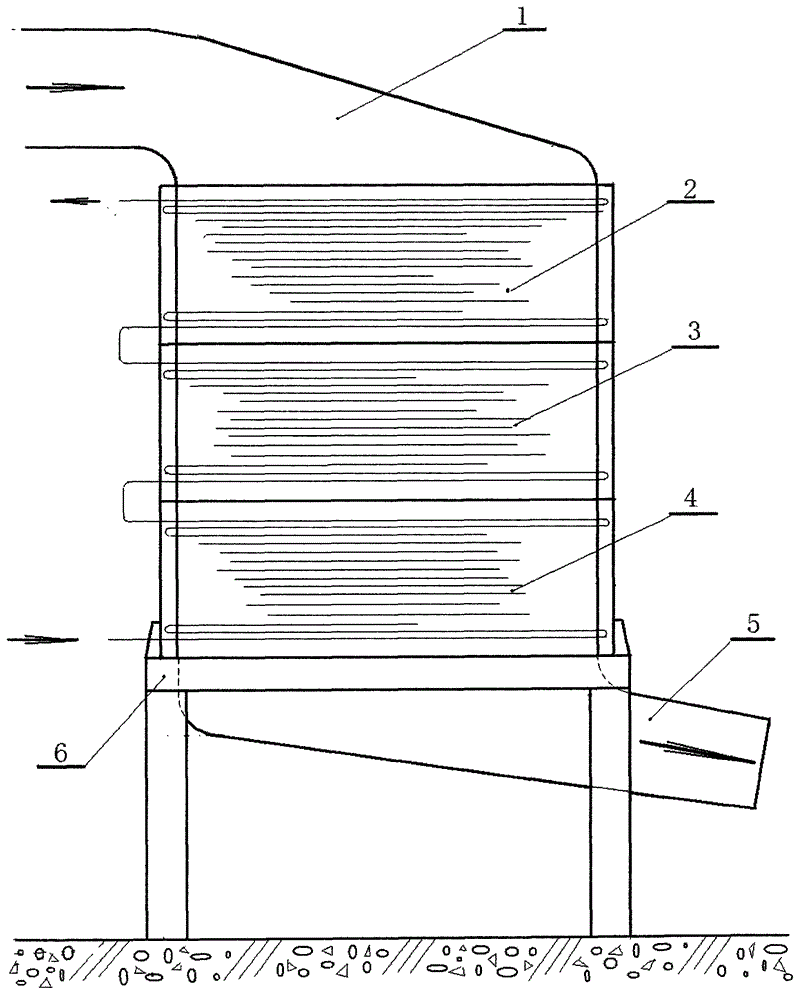

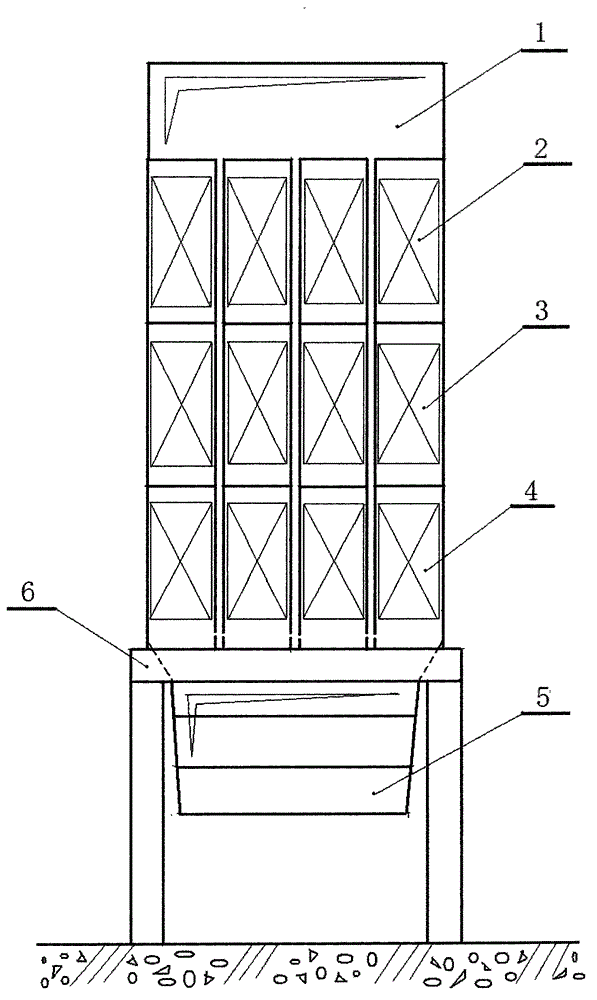

[0031] Combine now figure 1 , figure 2 The optimal way of realizing the invention is illustrated by taking an ultra-low temperature economizer configured with a 1100MW primary reheating unit as an example.

[0032] The ultra-low temperature economizer used in the primary reheating unit of the present invention adopts a completely different technical route from the prior art, and provides a kind of ultra-low temperature economizer used in the primary reheating coal-fired generating set, which replaces the low-pressure heater to heat the condensed water, and can dissipate the smoke The gas temperature is reduced to 50 ℃, and the ultra-low temperature economizer that recovers the latent heat of vaporization of the water vapor contained in part of the exhaust gas; it has the dual benefits of energy saving and environmental protection.

[0033] The technical feature of the ultra-low temperature economizer used in the primary reheating unit of the present invention is a condensing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com