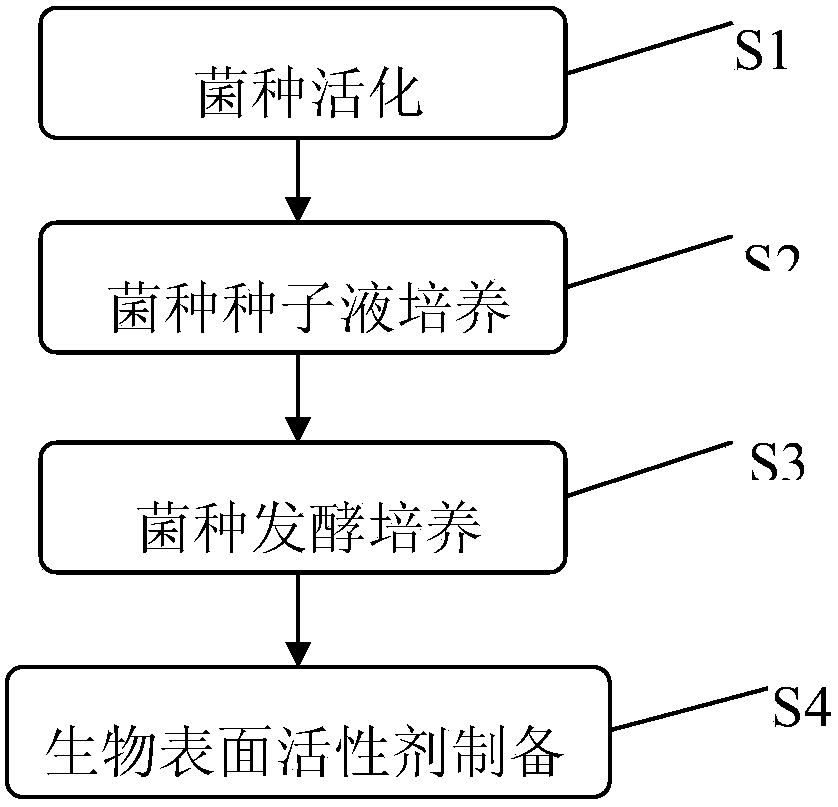

A kind of preparation method of rhodococcus producing surfactant

A technology for producing surfactants and rhodococcus, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of no large-scale production of biosurfactants, and achieve easy application and promotion, simple process, The effect of good emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, preparation fermentation medium

[0027] The fermentation medium is an inorganic salt medium.

[0028] Prepare 60L of liquid fermentation medium: 150g of urea, 60g of K2HPO4, 45g of KH2PO4, 30g of MgSO4·7H2O, add tap water to make up to 60L, adjust the pH to 7.0, add 1200g of soybean oil, and sterilize at 121°C for 30min.

[0029] Prepare 100 mL of solid fermentation medium: 0.25 g of urea, 0.1 g of K2HPO4, 0.075 g of KH2PO4, 0.05 g of MgSO4 7H2O, add distilled water to 100 mL, adjust the pH to 7.0, add 2 g of soybean oil, and sterilize at 121 ° C for 30 min.

Embodiment 2

[0030] Embodiment 2, strain fermentation culture

[0031] Inoculate a single colony of Rhodococcus on the slant of the solid medium and culture it in a 30°C incubator for 1 day, then pick a single colony with an inoculation needle and inoculate it in 500 mL of liquid fermentation medium, and culture it for 1 day at 30°C and a shaker speed of 160 rpm. Obtain the seed liquid; inoculate all the seed liquid in 50L liquid fermentation medium, cultivate 24h under the conditions of 30°C, stirring speed 160rpm, ventilation rate 30slpm (guarantee dissolved oxygen 30%), and obtain the fermentation culture liquid.

Embodiment 3

[0032] Embodiment 3, preparation biosurfactant finished product

[0033] After the fermentation stopped, the tank was removed, and the pH value of the fermentation medium was adjusted to 2 with HCl (5N), and it was allowed to stand at room temperature for 6 h; Remove excess water; extract the paste with chloroform / methanol (1:1) solution, and dry it by rotary evaporation at 70°C and 80rpm to obtain 1.128kg of finished biosurfactant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com