A kind of precision casting automatic cutting device and method

An automatic cutting device and precision casting technology, which is applied in the field of precision casting, can solve problems such as low production efficiency, high risk factor, and high labor intensity, and achieve strong applicability, simple equipment, and the effect of solving alignment problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

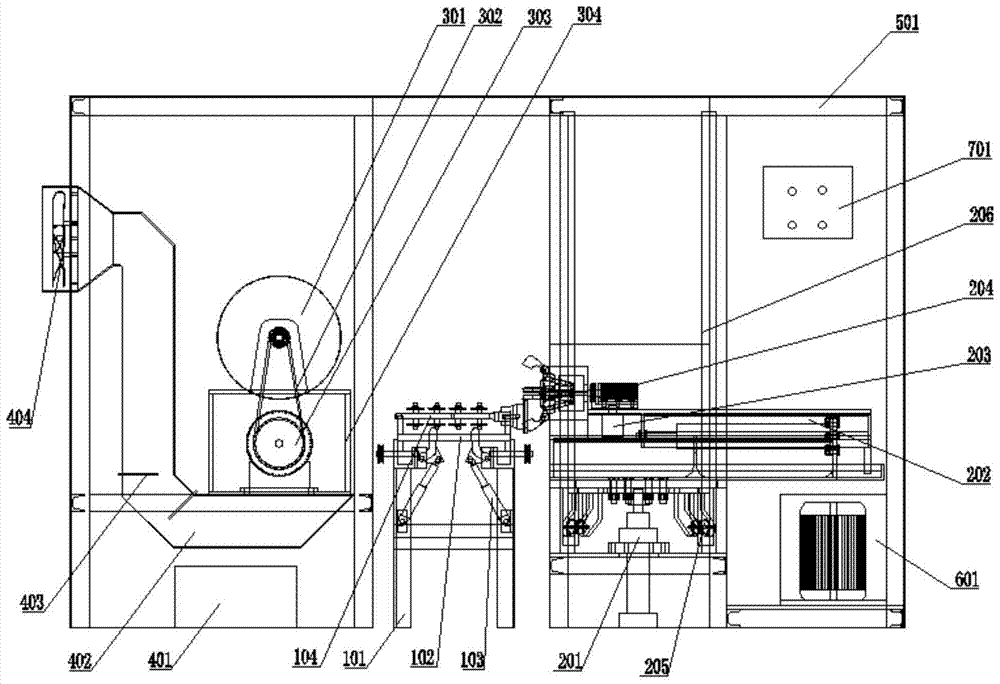

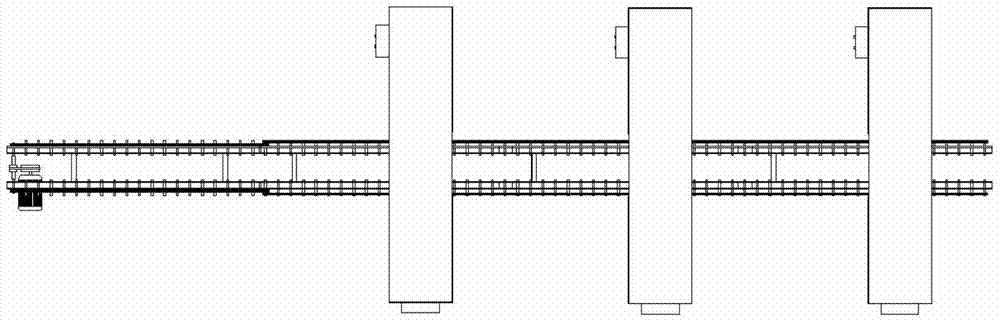

[0034] A casting automatic cutting device, such as figure 1 shown, including:

[0035] Rack 501;

[0036] The automatic transportation system includes: a transmission device 101 passing through the frame 501 , a casting standard pallet 102 placed on the transmission device 101 , and a limit mechanism 103 installed on the transmission device 101 .

[0037] The automatic pick-up system includes: a jacking device 201, a feeding device 202 installed on the jacking device 201, a rotating device 203 installed at one end of the feeding device, and a clamping device 204 installed at one end of the rotating device.

[0038] The cutting machine system includes: the saw blade 301 is connected with the motor 303 through the belt 302, the motor 303 is installed on the base 304, and the base is installed on the frame 501.

[0039] And a set of hydraulic sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com