High-temperature electric dust-removing system for flue gas of industrial kilns

An electrostatic precipitator and kiln technology, applied in the direction of electrode structure, electrostatic separation, electrode cleaning, etc., to achieve the effects of small thermal deformation, small secondary dust, and high dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A preferred embodiment of the present invention will be specifically introduced below in conjunction with the accompanying drawings.

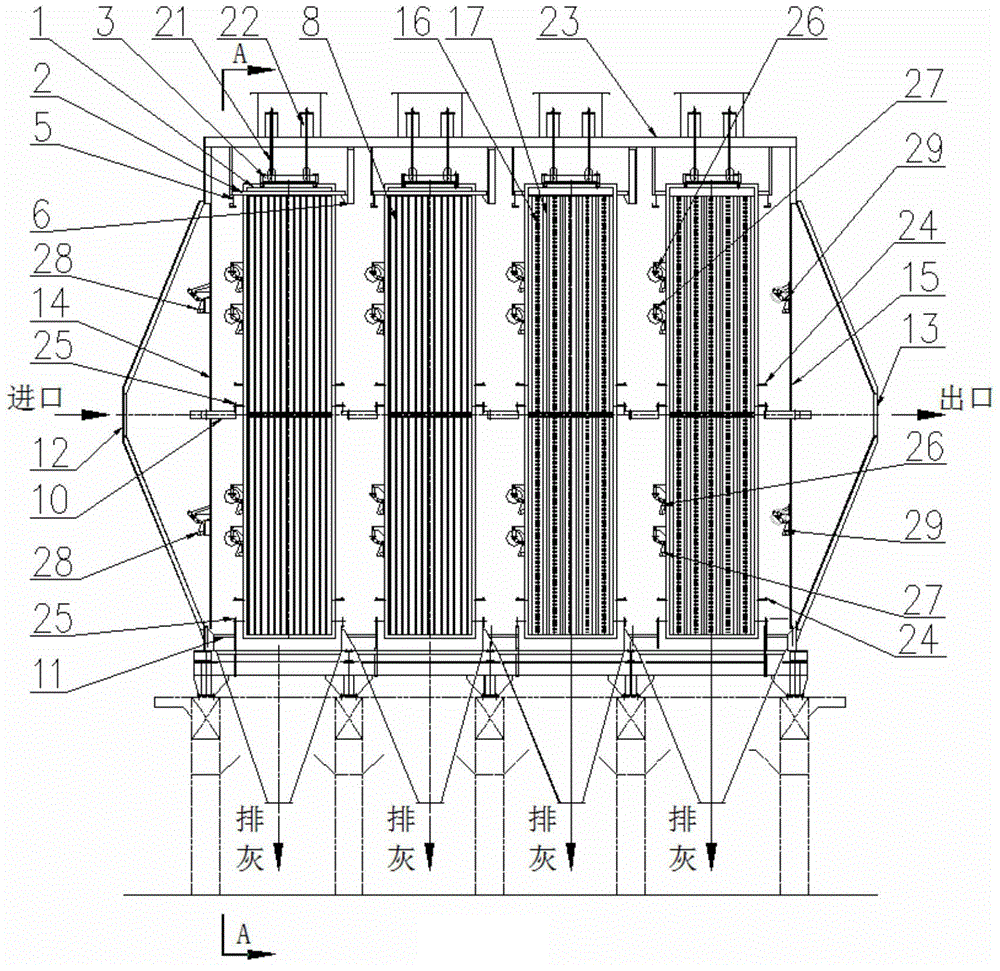

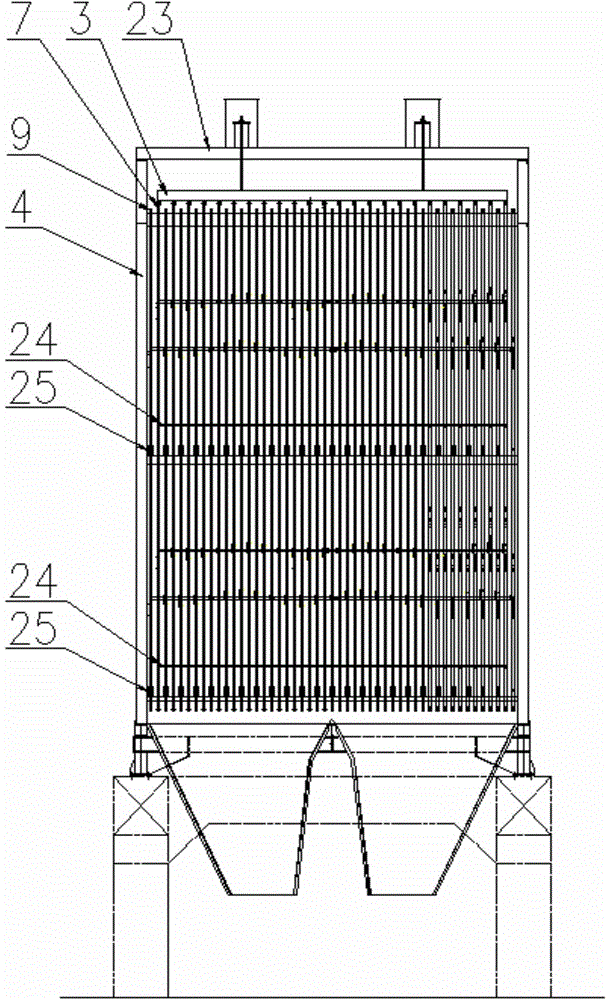

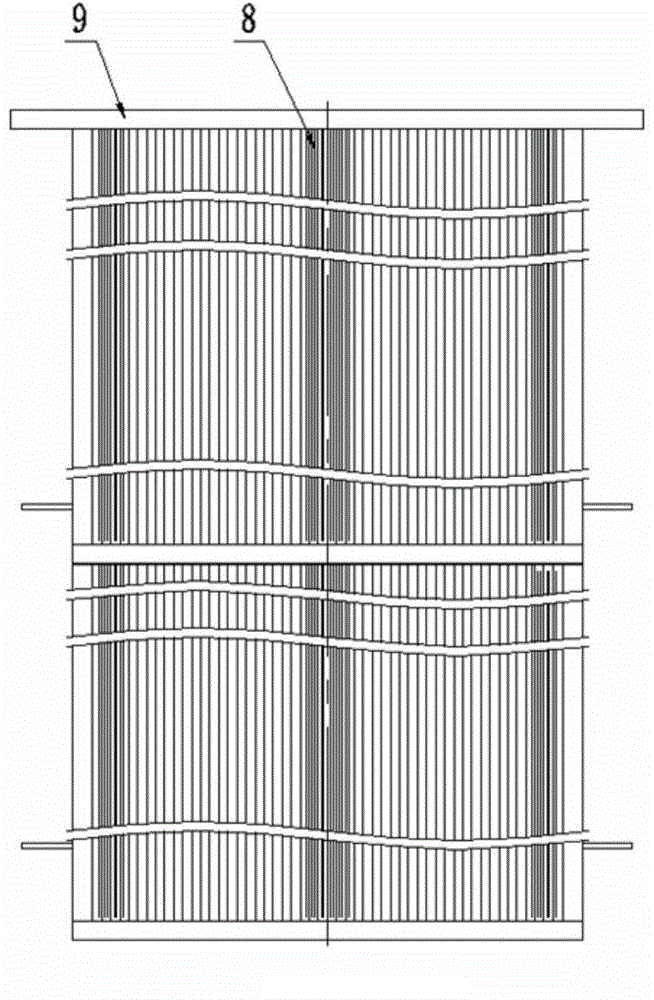

[0028] Such as figure 1 As shown, the industrial kiln flue gas high-temperature electrostatic precipitator system of the present invention includes a shell 4, and four sets of high-voltage electric fields are arranged in the shell 4. According to needs, there may be more than four sets or less than four sets. Both sides of the housing 4 are provided with an inlet 12 and an outlet 13, an inlet distribution plate 14 is provided between the inlet 12 and the electric field, an outlet distribution plate 15 is provided between the outlet 13 and the electric field, and an ash discharge port is provided below the electric field; The group of high-voltage electric fields is composed of multiple rows of vertically arranged dust collecting electrodes 8 , discharge electrodes 16 and auxiliary electrodes 17 . Such as Figure 5 As shown, the dust co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com