Polyacrylic acid-calcium phosphate composite nano-drug carrier and preparing method and application thereof

A nano-drug carrier, polyacrylic acid technology, applied in the direction of pharmaceutical formulations, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve the problems of difficult pharmaceutical preparations, easy agglomeration, precipitation, etc., to avoid Toxic and side effects, environmentally friendly production process, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

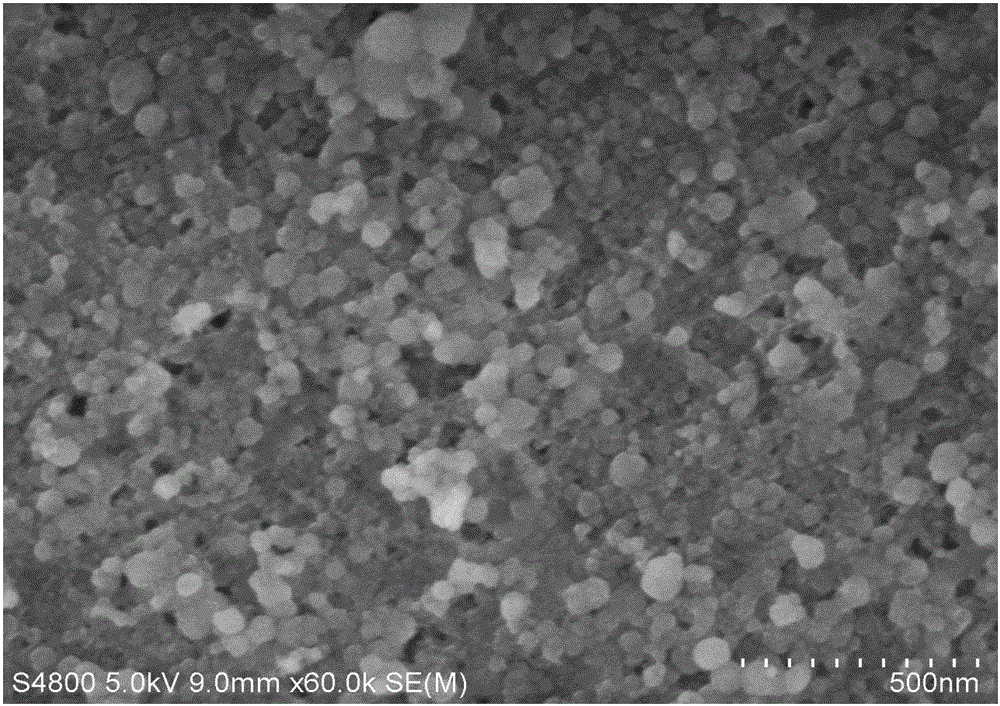

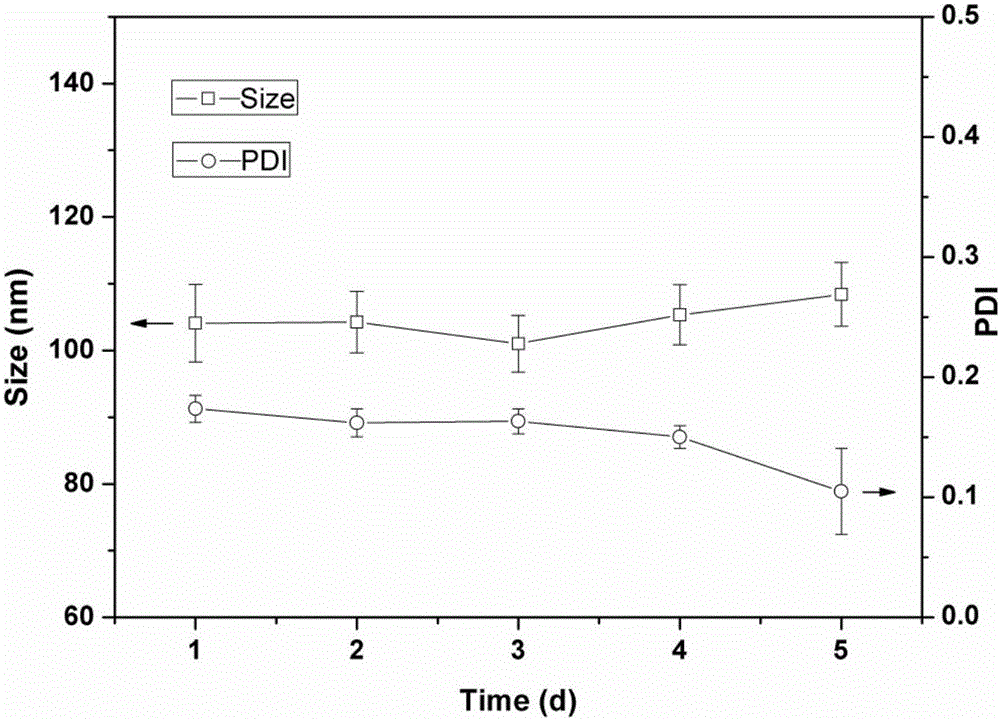

[0027] First, prepare 20 mL of calcium nitrate aqueous solution, Ca 2+ The concentration is 0.0334mol / L; prepare 20mL diammonium hydrogen phosphate aqueous solution, PO 4 3- The concentration is 0.02mol / L. According to the molar ratio Ca / P=1.67, quickly pour the diammonium hydrogen phosphate solution into the calcium nitrate solution at room temperature, adjust the pH value to 10 with ammonia water, stir and mix evenly, react for 20 minutes, centrifuge to obtain the precipitate, and wash with deionized water three times After redispersing in 40mL of deionized water, polyacrylic acid was added (the concentration after adding the solution was 0.3mg / mL), and the high-energy ultrasonic probe was ultrasonically dispersed for 4 minutes to obtain a stable polyacrylic acid-calcium phosphate composite nanoparticle suspension. The average particle size (ZAve) recorded by the laser particle size analyzer is 99.2nm, and the polydispersity index (PDI) is 0.167 (such as figure 1 shown), ...

Embodiment 2

[0029] First, prepare 20 mL of calcium nitrate aqueous solution, Ca 2+ The concentration is 0.0334mol / L; prepare 20mL diammonium hydrogen phosphate aqueous solution, PO 4 3- The concentration is 0.02mol / L. According to the molar ratio Ca / P=1.67, quickly pour the diammonium hydrogen phosphate solution into the calcium nitrate solution at room temperature, adjust the pH value to 10 with ammonia water, stir and mix evenly, react for 20 minutes, centrifuge to obtain the precipitate, and wash with deionized water three times Then re-disperse in 40mL deionized water, then add polyacrylic acid (concentration after adding the solution is 0.7mg / mL), and ultrasonically disperse with a high-energy ultrasonic probe for 4 minutes to obtain a stable polyacrylic acid-calcium phosphate composite nanoparticle suspension. The average particle size (ZAve) recorded by the laser particle size analyzer is 121.9nm, and the polydispersity index (PDI) is 0.151 (such as Figure 4 shown), the scannin...

Embodiment 3

[0031] First, prepare 20 mL of calcium nitrate aqueous solution, Ca 2+ The concentration is 0.03mol / L; prepare 20mL diammonium hydrogen phosphate aqueous solution, PO 4 3- The concentration is 0.02mol / L. According to the molar ratio Ca / P=1.5, quickly pour the diammonium hydrogen phosphate solution into the calcium nitrate solution at room temperature, adjust the pH value to 9 with ammonia water, stir and mix evenly, react for 20 minutes, centrifuge to obtain the precipitate, and wash with deionized water three times Then re-disperse in 40mL deionized water, then add polyacrylic acid (the concentration after adding the solution is 0.3mg / mL), and ultrasonically disperse for 4 minutes with a high-energy ultrasonic probe to obtain a stable polyacrylic acid-calcium phosphate composite nanoparticle suspension.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com