Sodium prasterone sulfate sustained-release tablet and preparation method thereof

A technology of prasterone sulfate sodium and slow-release tablets, which is applied in the direction of pharmaceutical formulas, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., and can solve problems that need to be deepened

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

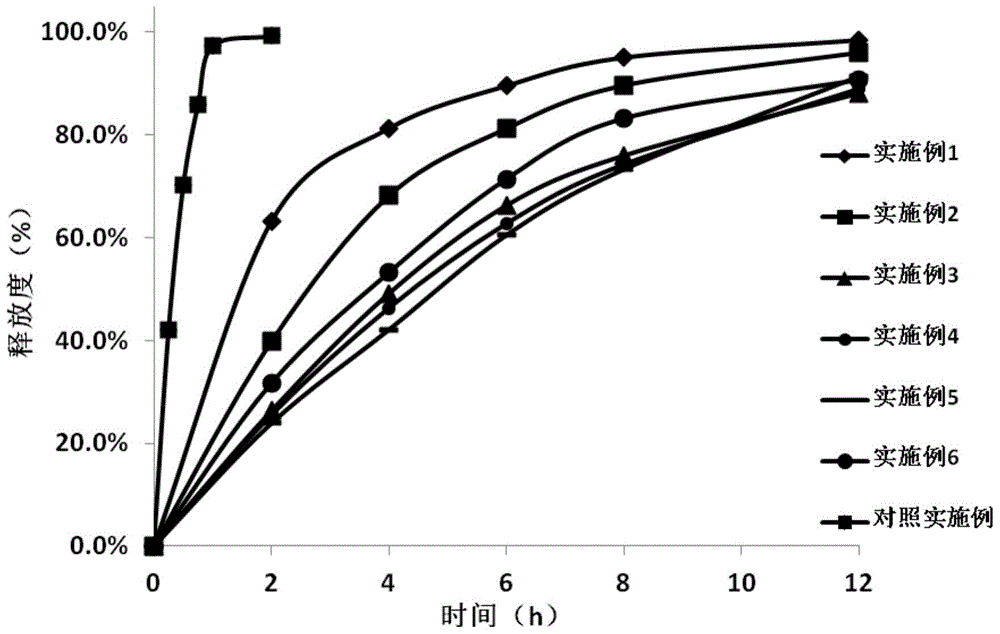

Image

Examples

preparation example Construction

[0049] According to the second aspect of the present invention, the present invention also proposes a method for preparing the aforementioned prasterone sulfate sodium sustained-release tablet. The preparation method of the prasterone sulfate sodium sustained-release tablet according to specific embodiments of the present invention comprises:

[0050] (1) Prasterone Sulfate Sodium, skeleton material and filler are mixed;

[0051] (2) Add binder to the mixture obtained in step (1), and make soft material successively, granulate, and dry;

[0052] (3) Sizing the granules obtained through the drying, adding a lubricant, mixing evenly, and compressing into tablets to obtain the prasterone sulfate sodium sustained-release tablets.

[0053] Thus, the present invention has prepared Prasterone Sulfate Sodium Sustained-release Tablets by adopting the above-mentioned wet granulation tableting technology. According to a specific embodiment of the present invention, the prasterone sulfa...

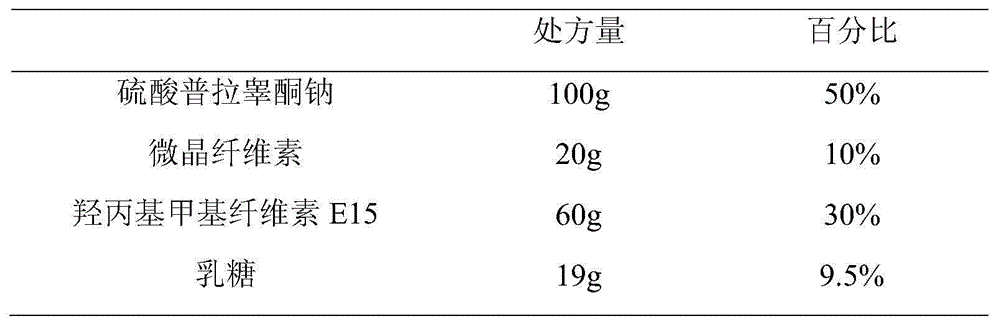

Embodiment 1

[0066]

[0067]

[0068] Preparation:

[0069] (1) Pass through an 80-mesh sieve after the raw and auxiliary materials are pulverized respectively, and set aside;

[0070] (2) Take by weighing prasterone sulfate sodium and hydroxypropyl methylcellulose E15 of prescription quantity and mix for 3 minutes, add microcrystalline cellulose and lactose of prescription quantity and mix for 2 minutes;

[0071] (3) Add an appropriate amount of ethanol to make a soft material, pass through a 24-mesh sieve to granulate, and dry in an oven at 60 degrees Celsius for 1 hour;

[0072] (4) Cross a 26-mesh sieve for granulation, add magnesium stearate in the prescribed amount, mix evenly, and compress the tablet, and the pressure is controlled at 6-7 kg during tablet compression.

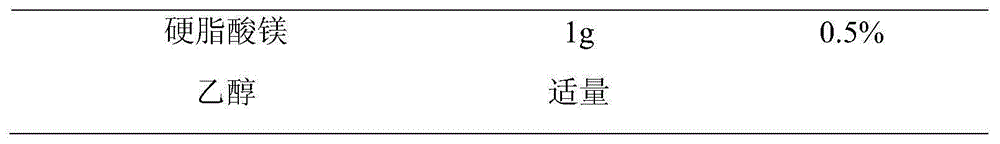

Embodiment 2

[0074] (Specification 100mg, 1000 tablets):

[0075]

[0076] Preparation:

[0077] (1) Pass through a 60-mesh sieve after the raw and auxiliary materials are pulverized respectively, and set aside;

[0078] (2) Take by weighing prasterone sulfate sodium and hydroxypropyl methylcellulose K4M of prescription quantity and mix for 3 minutes, add microcrystalline cellulose and lactose of prescription quantity and mix for 2 minutes;

[0079] (3) adding an appropriate amount of ethanol to make a soft material, passing through an 18-mesh sieve to granulate, and drying in an oven at 40 degrees Celsius for 2 hours;

[0080] (4) Cross a 26-mesh sieve for granulation, add magnesium stearate in the prescribed amount, mix evenly, and compress the tablet, and the pressure is controlled at 7-8 kg during tablet compression.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com