Preparation method and application of bicontinuous-structural nanocomposite material

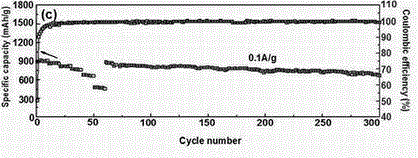

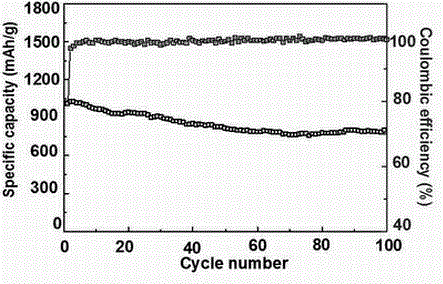

A nanocomposite, bicontinuous technology, applied in structural parts, active material electrodes, electrical components, etc., can solve the problems of low electronic conductivity, poor rate performance, and poor cycle performance of silicon materials, and achieve high specific capacity, The effect of good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0024] A method for preparing a silicon-carbon continuous dual-phase composite material, the basic implementation process of which is as follows:

[0025] Step 1, the purpose is to prepare porous silicon dioxide with suitable particle size and relatively pure. That is, the raw material diatomite should be pre-treated. The method is: constant temperature calcining in the air atmosphere to remove the organic matter and keep the porous structure from being destroyed. The temperature setting was changed from 5°C / min to 400°C at a heating rate of 1°C / min. After reaching 700°C and keeping the temperature unchanged for 120 minutes, natural cooling can be carried out. The orange color of the calcined diatomite indicates that it contains some impurities of metal oxides. It was refluxed in 6M sulfuric acid at 98° C. for 10 hours to remove these impurities. Wash it with water and ethanol until it becomes neutral, and after drying, it becomes a white powder. At this time, relatively pu...

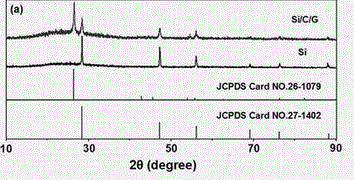

Embodiment 1

[0031] Diatomaceous earth was calcined at constant temperature under air atmosphere to remove organic matter and keep the porous structure from being destroyed. The temperature setting was changed from 5°C / min to 400°C at a heating rate of 1°C / min. After reaching 700°C and keeping the temperature unchanged for 120 minutes, natural cooling can be carried out. The orange color of the calcined diatomite indicates that it contains some impurities of metal oxides. It was refluxed in 6M sulfuric acid at 98° C. for 10 hours to remove these impurities. Wash it with water and ethanol until it becomes neutral, and after drying, it becomes a white powder. At this time, relatively pure diatomite with silicon dioxide as the main component is obtained. It is ball milled in a ball mill to reduce its particle size. The milling time was set at 10 hours, the rotation speed was 4000 rpm, and the dispersant was ethanol. After ball milling, dry it for later use.

[0032] Carry out magnesium th...

Embodiment 2

[0036] Diatomaceous earth was calcined at constant temperature under air atmosphere to remove organic matter and keep the porous structure from being destroyed. The temperature setting was changed from 5°C / min to 400°C at a heating rate of 1°C / min. After reaching 700°C and keeping the temperature unchanged for 120 minutes, natural cooling can be carried out. The orange color of the calcined diatomite indicates that it contains some impurities of metal oxides. It was refluxed in 6M sulfuric acid at 98° C. for 10 hours to remove these impurities. Wash it with water and ethanol until it becomes neutral, and after drying, it becomes a white powder. At this time, relatively pure diatomite with silicon dioxide as the main component is obtained. It is ball milled in a ball mill to reduce its particle size. The milling time was set at 10 hours, the rotation speed was 4000 rpm, and the dispersant was ethanol. After ball milling, dry it for later use.

[0037] The diatomite obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com