Preparation method and application of kapok fiber non-woven mask base material

The technology of kapok fiber and kapok fiber web is applied in the field of beauty and skin care, which can solve the problems of small decrease of the breaking strength of the blended yarn, decrease of the elongation at break of the blended yarn, large hollowness, etc., and achieves good water locking and hand feeling. Almost transparent, low specific gravity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

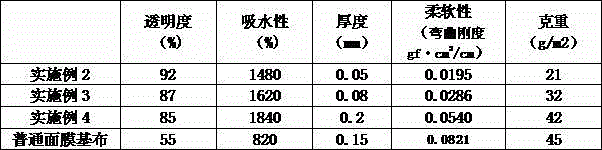

Examples

Embodiment 1

[0036] Carry out light alkali partial degreasing pretreatment to kapok fiber;

[0037] The kapok fibers damaged into flat strips during the pretreatment process are restored to hollowness and softened;

[0038] Dehydrating and drying the kapok fiber after the hollowness recovery and softening treatment, to obtain the kapok fiber with good spinnability;

[0039] After the kapok fiber after dehydration and drying treatment is opened, mixed and carded, a kapok fiber web is obtained;

[0040] The kapok fiber web is reinforced by a high-pressure jet method, so that the fibers in the kapok fiber web are entangled with each other;

[0041] drying the reinforced kapok fiber web to obtain the kapok fiber non-woven mask substrate.

Embodiment 2

[0043] Imported kapok fiber is selected, the length is 16mm, and the kapok fiber is treated by light alkali partial degreasing pretreatment process. The process is as follows:

[0044] a. Use light alkali solution for degreasing pretreatment, the bath ratio of the light alkali solution is 1:50, soda ash NaCO 3 The dosage is 0.1% (mass percentage), the soap dosage is 0.2% (mass percentage), the penetrant dosage is 0.5% (mass percentage), the treatment temperature is 30°C, and the treatment time is 30 minutes;

[0045] b. Wash the partially degreased kapok fiber with water until the pH value is neutral, then dehydrate and spin dry.

[0046] Then, restore the hollowness and softening treatment to the kapok fiber pretreated by the light alkali solution. The specific process is as follows:

[0047] a. Use ultrasonic waves to restore hollowness and soften the kapok fibers in a solution containing hydrophilic silicone oil, wherein the bath ratio of the solution is 1:100, and the amo...

Embodiment 3

[0052] Imported kapok fiber is selected, the length is 25mm, and the kapok fiber is treated by light alkali partial degreasing pretreatment process. The process is as follows:

[0053] a. Use light alkali solution to carry out degreasing pretreatment, the bath ratio of this light alkali solution is 1: 100, soda ash NaCO 3 The dosage is 0.3% (mass percentage), the soap dosage is 0.4% (mass percentage), the penetrant dosage is 0.8% (mass percentage), the treatment temperature is 50°C, and the treatment time is 45 minutes;

[0054] b. Wash the partially degreased kapok fiber with water until the pH value is neutral, then dehydrate and spin dry.

[0055] Then, restore the hollowness and softening treatment to the kapok fiber pretreated by the light alkali solution. The specific process is as follows:

[0056] a. Ultrasonic waves are used to restore hollowness and soften the kapok fiber in a solution containing hydrophilic silicone oil, wherein the bath ratio of the solution is 1:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com