Linaclotide solid-phase synthesis method

A technology of linaclotide and solid-phase synthesis, applied in the field of biochemistry, can solve the problems of unsuitability for large-scale production, difficult purification, high cost, etc., achieve considerable economic and practical value, simple reaction operation, and increase the effect of cyclization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

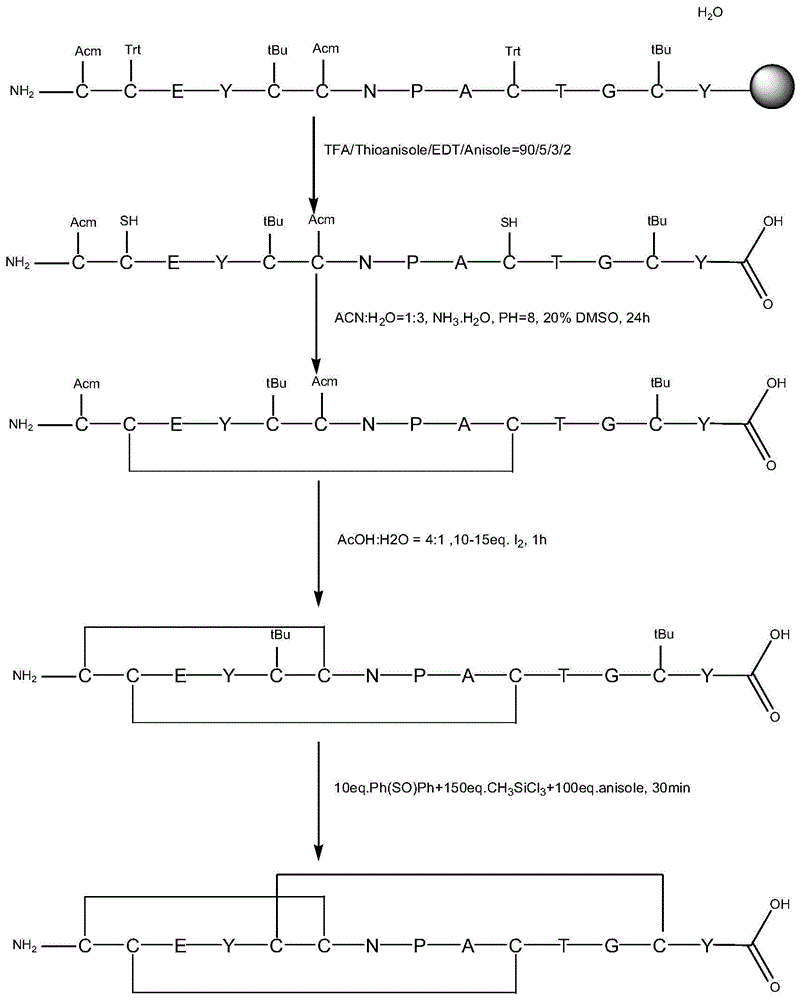

Method used

Image

Examples

Embodiment 1

[0064] Example 1: Preparation of Linaclotide Linear Fully Protected Peptide Resin.

[0065] (1) Resin swelling: Weigh 5g of 2-Chlorotrityl Chloride Resin (SD=0.84mmol / g), add it into a reactor with a sieve plate, and use dichloromethane twice the resin volume to swell twice, 30min each time, The dosage is 5-10ml / g resin each time, and dichloromethane is removed by suction filtration.

[0066] (2) Preparation of Fmoc-Tyr(tBu)-resin: Weigh the swollen resin, Fmoc-Tyr(tBu)-OH and DIPEA according to the molar ratio of 1:(1~2):(2~4), respectively, at room temperature Shake for 1-3 hours, add methanol (0.8-1ml / g resin) to the direct-phase reaction solution to block for 30 minutes. Then wash with dimethylformamide, dichloromethane, and methanol three times respectively, drain the resin, and detect that the degree of substitution is 0.5 mmol / g.

[0067] (3) Removal of the Fmoc protecting group: 50-80 ml of 20% piperidine / DMF (v / v) solution was added to the reactor, stirred at room t...

Embodiment 2

[0074] Example 2: Cleavage of linaclotide linear fully protected peptide resin.

[0075] (1) Add the linear fully protected peptide resin obtained in Example 1 into a 500ml round bottom flask, configure cutting agent 1 (trifluoroacetic acid, phenol, water, triisopropylsilane according to volume ratio 88:5:5:2 Mix) or cutting agent 2 (mix trifluoroacetic acid, thioanisole, ethanedithiol, and anisole in a volume ratio of 90:5:3:2), add 120ml (10ml / g) cutting agent to the circle In the bottom flask, shake at 720r / min for 3 hours.

[0076] (2) After the cutting reaction is completed, drop cutting solution 1 or cutting agent 2 into 10 times the volume of ice ether (-20°C), then add 20-30ml of cutting agent to the round bottom flask for cleaning, and take the supernatant and drop Pour into glacial ether and let it settle for half an hour. Centrifuge at 3500r / min at 4°C for 10min. Discard the supernatant, re-add glacial ether for ultrasonic washing, centrifuge at low temperature, ...

Embodiment 3

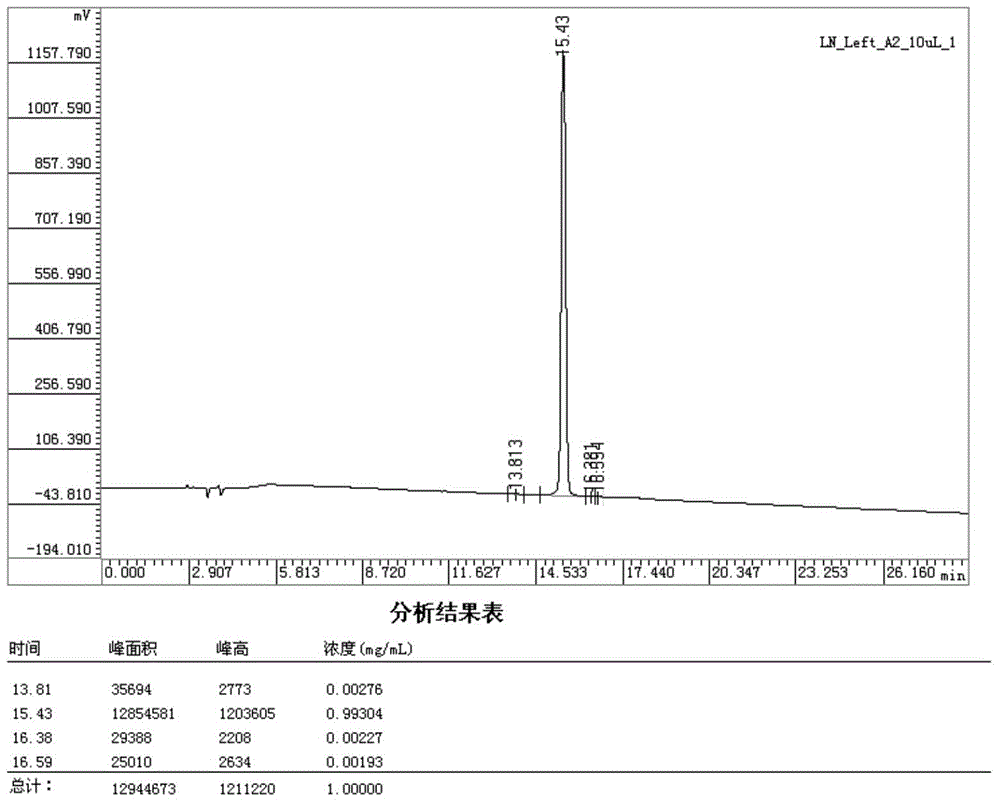

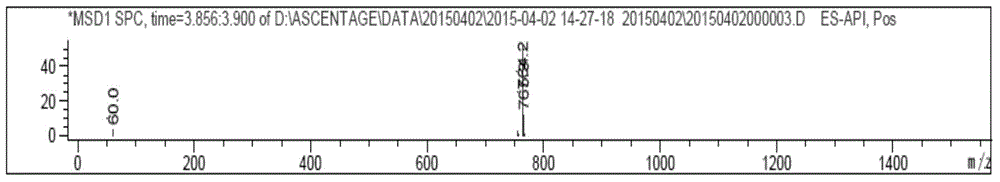

[0077] Example 3: Preparation of linaclotide single disulfide ring crude peptide.

[0078] (1) Add 300 mg of the linear peptide obtained in Example 2 into a 500 ml round bottom flask, add 300 ml of acetonitrile: water volume ratio of 1:3 and dissolve to a concentration of 1 mg / ml, adjust the pH to 8 with ammonia water, add 60 ml of DMSO , 640r / min room temperature shaking reaction for 24 hours.

[0079] (2) After the reaction is over, add 600ml of aqueous solution to terminate the reaction. The solution was lyophilized to obtain 296 mg of crude linaclotide monodithiocyclic peptide, with a crude yield of 98.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com