Five-axis robot gumming equipment and technology

A robot and gluing technology applied in the field of gluing to achieve the effects of shortened cleaning time, convenient installation and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

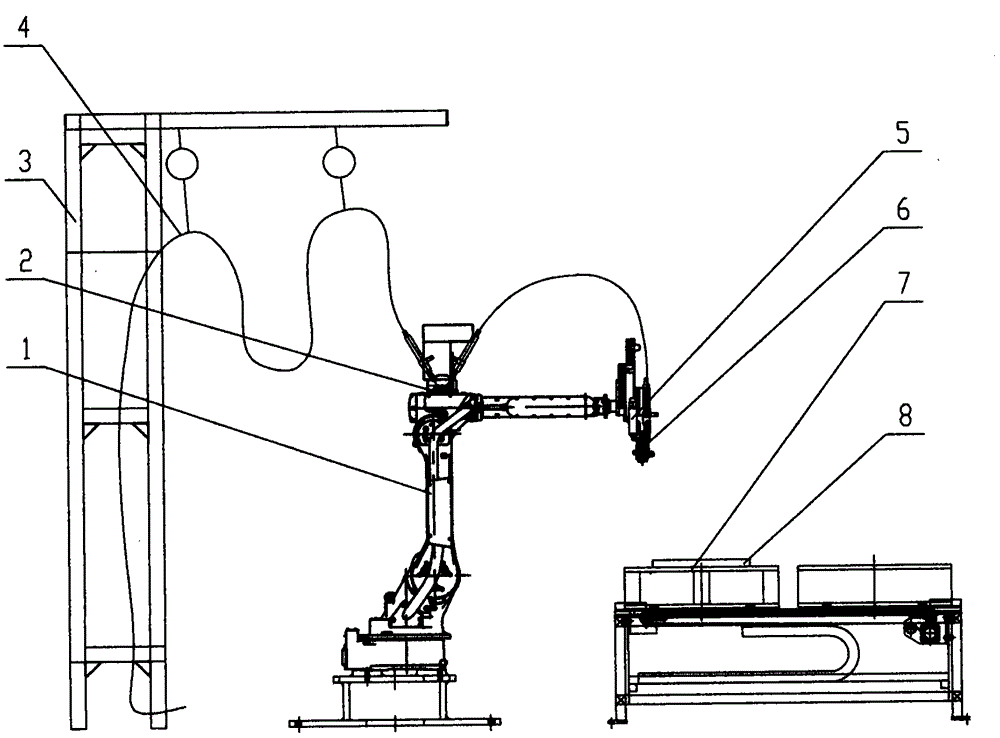

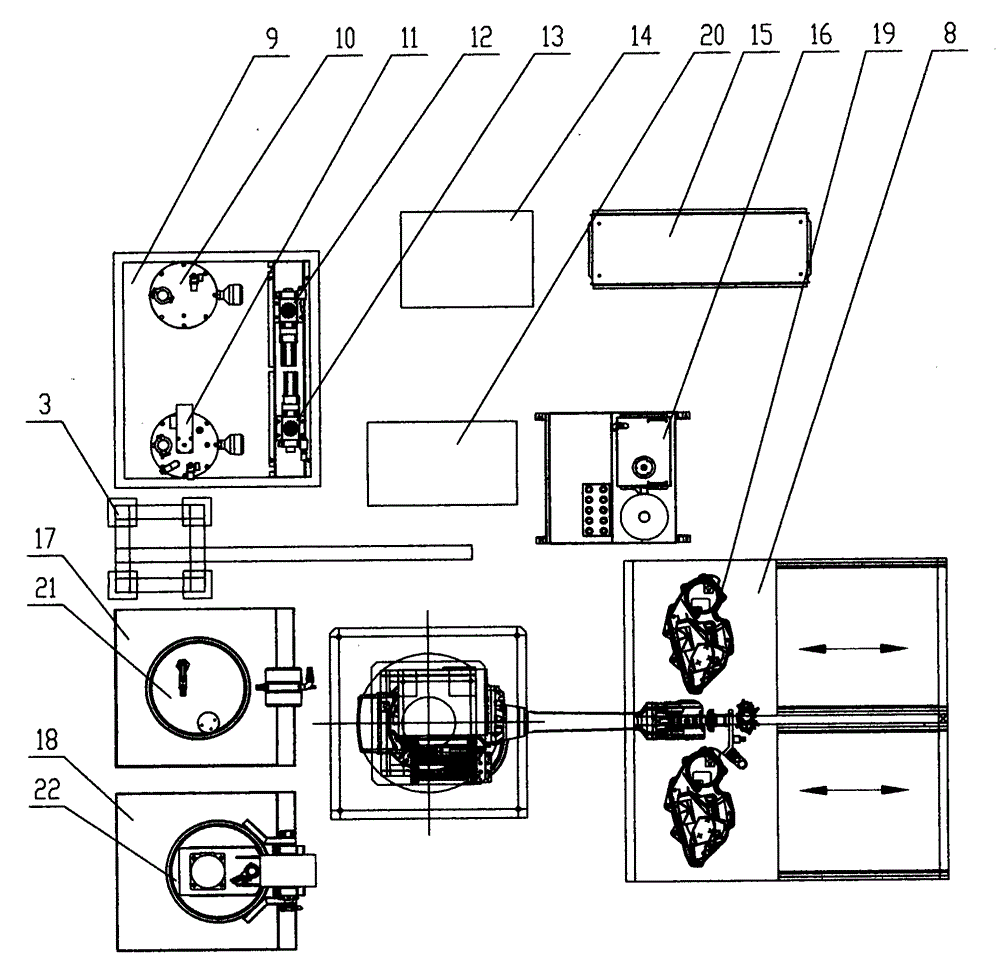

[0027] Specific implementation mode one: as Figure 1~4 As shown, a five-axis robot gluing equipment and process technology is characterized in that it includes a five-axis robot 1, a glue supply device 9, a two-component gluing head 6, a double-station automatic gluing workbench 8 or a multi-station Automatic rotary gluing workbench 23, plasma treatment equipment 20, cleaning waste liquid recovery device 16, intelligent control system;

[0028] The five-axis robot 1 is a five-joint robot. The workpiece 19 is placed on the double-station automatic gluing workbench 8 or the multi-station automatic rotating gluing workbench 23. The workpiece 19 is fixed or can be moved along a free degrees or two degrees of freedom to rotate or swing or move, the two-component gluing head 6 and the plasma processing head 5 can realize linkage with the five-axis robot 1; the five-axis robot 1 has the function of automatic control operation, can complete programmable operations, and can Realize a...

specific Embodiment approach 2

[0037] Specific implementation mode two: as Figure 1~4 As shown, the five-axis robot gluing equipment and process technology are characterized in that they include a five-axis robot 1, a glue supply device 9, a two-component gluing head 6, a double-station automatic gluing workbench 8 or multiple Automatically rotating gluing workbench 23, cleaning waste liquid recovery device 16, and intelligent control system; only automatic gluing work is realized on workpiece 19, and surface plasma treatment is not performed. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0038] Specific implementation mode three: as Figure 1~4 As shown, the five-axis robot gluing equipment and process technology are characterized in that the intelligent control system includes a robot control cabinet 14, an electric control cabinet 15, an industrial computer, a touch screen and control software, and the control system adopts an intelligent design, Automatic control five-axis robot 1, plasma processing equipment 20, double-station automatic gluing workbench 8 or multi-station automatic rotating gluing workbench 23, glue supply device 9, two-component gluing head 6. Other compositions and connections are the same as those in Embodiments 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com