Precharging circuit and photovoltaic inverter

A pre-charging circuit, photovoltaic inverter technology, applied in the direction of photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve the problems of low pre-charging voltage of DC bus, current impact, etc., to avoid current impact and solve pre-charging voltage. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

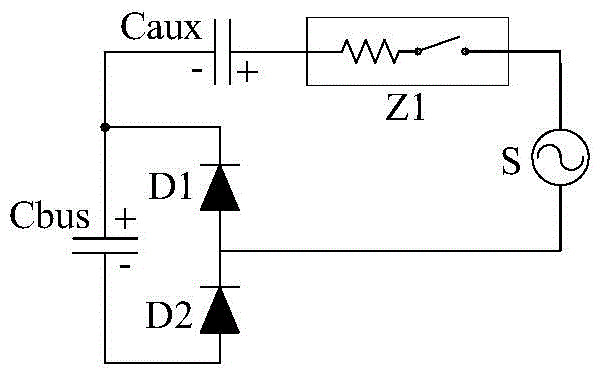

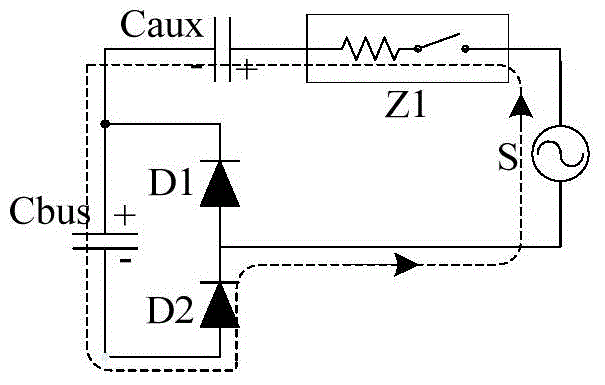

[0056] See Figure 2a For example, the pre-charging circuit has an AC power supply S, a rectifier half-bridge connected in series by a diode D1 and a diode D2, and an auxiliary charging capacitor Caux (in the figure, Z1 represents the series connected to the pre-charging circuit The only switching current limiting device on the charging path; Cbus represents the target charging capacitor. After reaching the charging steady state, the voltage across the target charging capacitor is the DC bus precharge voltage): when the AC power supply S is at the forward voltage, the charging path Such as Figure 2b As shown, the current flows through Z1, Caux, Cbus, and D2 to form a charging loop to charge Cbus and Caux positively; when the AC power supply S is at a negative voltage, the charging path is as follows Figure 2c As shown, the current flows through D1, Caux, and Z1 to form a charging loop to charge Caux in reverse. Since the positive charging loop impedance includes Caux and Cbus,...

example 2

[0067] See Figure 4a Take the pre-charging circuit with 1 AC power supply S, 1 rectifier half bridge connected in series by diodes D1 and D2, and 2 auxiliary charging capacitors Caux1~Caux2 as an example (switch current limiting device Z1 is connected in series with Caux1. On the path, the switching current limiting device Z3 is connected in series on the charging path where Caux2 is located, and the switching current limiting device Z3 is connected in series on the charging path shared by Caux1 and Caux2):

[0068] When the AC power supply S is at a forward voltage, there are two charging paths, such as Figure 4b As shown, one of the currents passes through Z2, D1, Cbus, Caux2, and Z3 to form a charging loop to charge Cbus and Caux2; the other current passes through Z2, D1, Caux1, and Z1 to form a charging loop to charge Caux1 in reverse. When the AC power supply S is at a negative voltage, there are two charging paths, such as Figure 4c As shown, one of the currents passes th...

example 3

[0079] In order to make the charging speed faster, the DC side load capacity with the inverter is stronger, and the three-phase power rectification can also be fully utilized. Such as Image 6 As shown, the pre-charging circuit includes 3 AC power supplies, 3 rectifying half bridges, 1 auxiliary charging capacitor Caux, and 4 switch current limiting devices. Image 6 versus Figure 2a The only difference is that the number of AC power supplies and rectifier half bridges has been increased, and the charging principle remains the same. Refer to Figure 2b~Figure 2c The relevant description can be.

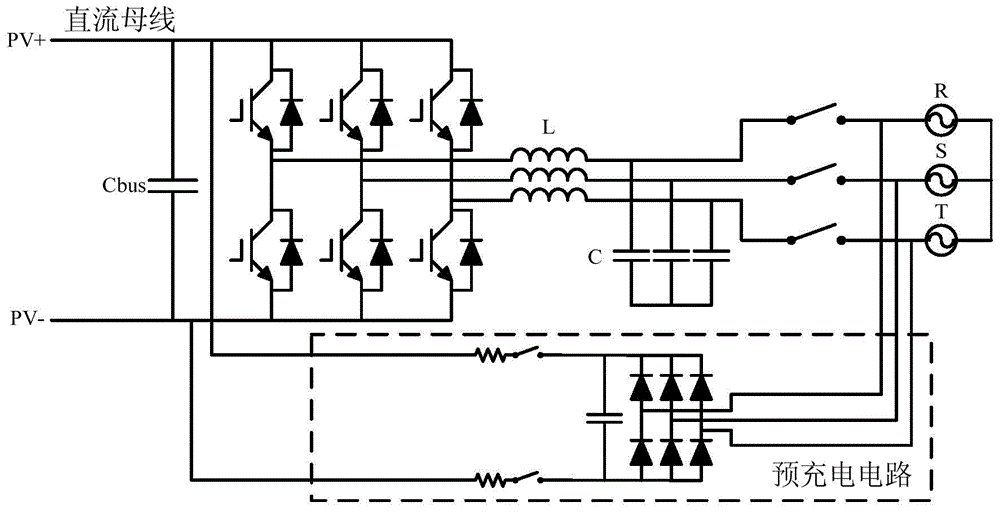

[0080] will Image 6 The circuit shown is applied to Figure 7 In the three-phase two-level photovoltaic inverter shown, additional auxiliary charging capacitors Caux1, three rectifier half bridges, and three switch current limiting devices Z1 to Z3 can be added to realize the pre-charging function. Comparison figure 1 It can be seen that Figure 7 The circuit shown is equivalent to dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com