A high-power motor frequency conversion switching system and a control method thereof

A switching system and electromechanical technology, applied in the field of frequency converters, can solve the problems of excitation shock, inconsistent initial phase, and low phase requirements of the motor, and achieve the effects of preventing current shock, increasing stability and success rate, and making the system simple and efficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

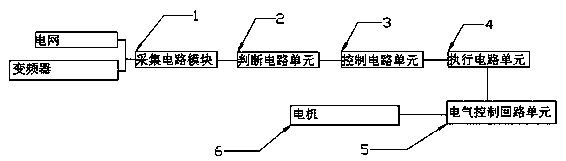

[0025] A frequency conversion switching system for high-power electrical engineering, including:

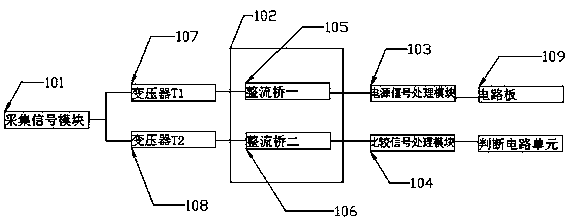

[0026] The acquisition circuit unit (1) is used to acquire the voltage of the two-phase electricity of the power grid and the two-phase electricity output by the frequency converter in the same phase;

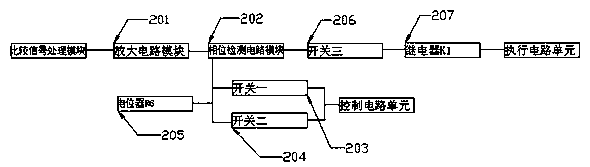

[0027] A judging circuit unit (2), used for comparing and processing the collected voltage and phase signals;

[0028] The control circuit unit (3) is used to control the acquisition circuit unit (1) and the judgment circuit unit (2) to perform back and forth actions until the corresponding control requirements are met;

[0029] The execution circuit unit (4) is mainly used to perform the conduction work of the electrical control circuit unit (5);

[0030] The electrical control circuit unit (5) controls the motor (6) to complete the phase-locking of the output waveform, and at the same time controls the main circuit switching circuit unit to complete the conversion of industrial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com